Tet . 13, 2024 19:50 Back to list

High-Quality Cold Drawn Wire Production at 10% Manufacturer

Exploring the World of 10% 20mm Cold Drawn Wire Manufacturing

The manufacturing of cold drawn wire is a critical component of various industries, contributing significantly to the production of high-quality products used in applications ranging from construction to automotive. Among the many specifications in wire production, the 10% 20mm cold drawn wire stands out due to its versatility and strength. This article explores the process of manufacturing this particular type of wire, its applications, and the benefits it offers.

Understanding Cold Drawn Wire

Cold drawing is a metalworking process used to reduce the diameter of a wire while increasing its length. This is achieved by pulling the wire through one or more die openings at room temperature. The process not only reduces the diameter but also enhances the mechanical properties of the wire, improving its tensile strength and ductility.

In the case of 10% 20mm cold drawn wire, the '10%' refers to the percentage of elongation applied during the cold drawing process, while '20mm' specifies the wire's diameter. This type of wire is characterized by its exceptional precision and uniformity, making it ideal for various manufacturing needs.

The Manufacturing Process

The production of 10% 20mm cold drawn wire involves several steps

1. Wire Rod Preparation The process begins with the selection of high-quality wire rods, usually made from low-carbon or medium-carbon steel. These rods are typically sourced from reputable steel mills, ensuring that they meet the necessary standards.

2. Cleaning and Descaling Before drawing, the wire rods are cleaned to remove any surface impurities, oils, or scales. This is usually done through chemical or mechanical methods to ensure a smooth surface for the drawing process.

3. Annealing To improve the ductility of the wire rod, an annealing process is often performed. This involves heating the wire rod to a specific temperature before slowly cooling it down, relieving internal stresses and making it easier to draw.

4. Cold Drawing The cleaned and annealed wire rod is then drawn through dies of decreasing diameter. This process is repeated until the desired diameter of 20mm is achieved, while ensuring that the wire maintains a uniform cross-section throughout its length.

5. Final Treatment After the wire has been drawn to specifications, it may undergo additional treatments such as tempering or surface coating to enhance its properties further. This step is vital for improving the wire’s resistance to corrosion and wear.

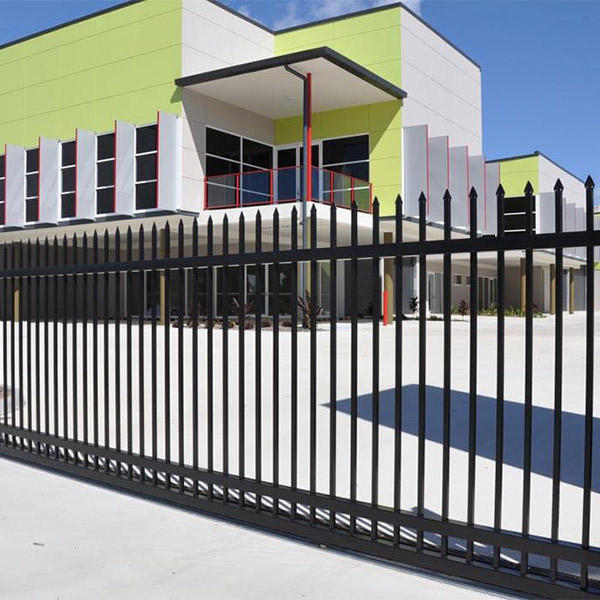

10 mm cold drawn wire factory

Applications of 10% 20mm Cold Drawn Wire

The 10% 20mm cold drawn wire finds applications in various fields, such as

- Construction Due to its strength and durability, this type of wire is frequently used in the reinforcement of concrete structures, providing added strength to buildings, bridges, and other infrastructures.

- Automotive Industry The automotive sector utilizes cold drawn wire in the production of components such as springs, cables, and various fasteners. Its high tensile strength and precision make it ideal for critical applications.

- Manufacturing Manufacturers often use this wire in the production of machinery and equipment where reliability and durability are paramount. The wire can be found in gears, pulleys, and other critical components.

Benefits of 10% 20mm Cold Drawn Wire

Utilizing 10% 20mm cold drawn wire offers several advantages

- High Mechanical Properties The cold drawing process enhances the tensile and yield strength of the wire, making it suitable for heavy-duty applications.

- Precision and Uniformity The manufacturing process ensures that the wire has a consistent diameter and surface finish, which is essential for applications in high-precision environments.

- Cost-Effectiveness Producing cold drawn wire is often more cost-effective compared to other methods due to the reduced need for secondary processing.

Conclusion

The 10% 20mm cold drawn wire is a remarkable product born from meticulous manufacturing processes that enhance its mechanical properties and performance. Its widespread applications in construction, automotive, and manufacturing sectors underline its importance in modern industry. As technology advances, the demand for such high-quality wire products is expected to grow, driving innovations in manufacturing techniques and materials selection. Industries can look forward to continued advancements that enhance the performance and applications of cold drawn wire products.

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025