Jan . 14, 2025 10:19 Back to list

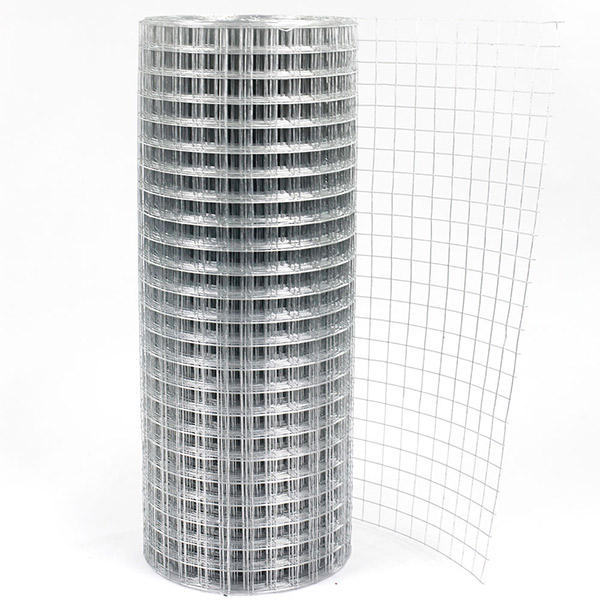

galvanized brick coil wire mesh masonry factories

In the realm of industrial materials, hot galvanized wire stands out due to its multifaceted utility and cost-effective nature. This article delves into the intricate world of hot galvanized wire, offering an expert analysis backed by industry experience, underscoring its unbeatable value proposition for businesses worldwide.

Trustworthiness is further established through transparent business practices and customer testimonials. Companies offering hot galvanized wire at competitive prices frequently provide detailed product specifications, certifications, and performance data, helping clients make informed purchasing decisions. Customers consistently report positive experiences, praising the product's durability and the cost savings realized over time. In practical applications, hot galvanized wire has carved a niche for itself in sectors such as telecommunications, where it serves as a dependable grounding material due to its excellent conductivity and resistance to elements. In the agricultural domain, its use in making sturdy farm fences ensures livestock safety and crop protection, all while maintaining a lower budgetary footprint. As industries continue to evolve, the demand for reliable, affordable materials like hot galvanized wire is poised to rise. Companies that prioritize integrating high-quality galvanized wire into their operations are likely to experience improved efficiency and reduced maintenance costs. This strategy not only supports sustainable growth but also demonstrates a commitment to leveraging expert-approved, authoritative solutions to meet modern industrial challenges. In summary, hot galvanized wire presents an unparalleled blend of affordability, reliability, and versatility. By leveraging advanced production expertise and adhering to stringent quality standards, manufacturers ensure that this material remains an indispensable asset across various sectors. Buyers can confidently invest in hot galvanized wire, knowing they are supported by a product that combines proven performance with exceptional economic value.

Trustworthiness is further established through transparent business practices and customer testimonials. Companies offering hot galvanized wire at competitive prices frequently provide detailed product specifications, certifications, and performance data, helping clients make informed purchasing decisions. Customers consistently report positive experiences, praising the product's durability and the cost savings realized over time. In practical applications, hot galvanized wire has carved a niche for itself in sectors such as telecommunications, where it serves as a dependable grounding material due to its excellent conductivity and resistance to elements. In the agricultural domain, its use in making sturdy farm fences ensures livestock safety and crop protection, all while maintaining a lower budgetary footprint. As industries continue to evolve, the demand for reliable, affordable materials like hot galvanized wire is poised to rise. Companies that prioritize integrating high-quality galvanized wire into their operations are likely to experience improved efficiency and reduced maintenance costs. This strategy not only supports sustainable growth but also demonstrates a commitment to leveraging expert-approved, authoritative solutions to meet modern industrial challenges. In summary, hot galvanized wire presents an unparalleled blend of affordability, reliability, and versatility. By leveraging advanced production expertise and adhering to stringent quality standards, manufacturers ensure that this material remains an indispensable asset across various sectors. Buyers can confidently invest in hot galvanized wire, knowing they are supported by a product that combines proven performance with exceptional economic value.

Next:

Latest news

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025