Jul . 04, 2025 11:06 Back to list

High Quality Deformed Steel Bars China - Leading Manufacturers & Suppliers

- Introduction: Overview of the Deformed Steel Bars Market in China

- Market Data and Growth Trends

- Technical Advantages of Deformed Steel Bars

- Comparison of China Deformed Steel Bars Manufacturers and Suppliers

- Customized Solutions and Product Offerings

- Application Cases and Industry Impacts

- Conclusion: Why Choose Deformed Steel Bars China for Your Projects

(deformed steel bars china)

Introduction: The Booming Market for Deformed Steel Bars China

The demand for deformed steel bars China has surged over the past decade, driven by vast infrastructural projects and rapid urban development. Both local and global contractors rely on these high-strength bars to reinforce concrete structures, ensuring safety and longevity. The affinity for deformed steel bars stands on their mechanical properties and wide acceptance in diverse applications—commercial, residential, and industrial. In this overview, we examine why this market has become central to construction progress and how China deformed steel bars China are setting new standards in the industry.

Market Data and Growth Trends

China is the world’s largest producer and consumer of steel products, accounting for nearly 54% of global crude steel production in 2023 (World Steel Association). The deformed steel bars segment forms a sizeable portion, with annual output exceeding 250 million tons in 2023 alone. Demand is spurred by ambitious infrastructure investments, such as the Belt and Road Initiative and urban renewal policies. Export data shows that deformed steel bars from China make up approximately 40% of global exports, with major destinations including Southeast Asia, Africa, and the Middle East. The table below summarizes key market figures:

| Year | China Output (Million Tons) | Export Volume (Million Tons) | Global Market Share (%) | Top Export Destinations |

|---|---|---|---|---|

| 2021 | 230 | 87 | 36 | Southeast Asia, Africa |

| 2022 | 241 | 95 | 39 | Middle East, South America |

| 2023 | 251 | 102 | 40 | Southeast Asia, Africa |

These figures underscore how China’s production capabilities and logistics efficiency support its dominant marketplace position. With infrastructure projects slated to rise by 8% year-on-year through 2027 (KPMG Infrastructure Outlook), the trajectory points to sustained market growth.

Technical Advantages of Deformed Steel Bars

Deformed steel bars are characterized by their ribbed surface, which enhances the mechanical interlocking with concrete, significantly increasing load-bearing capacity. Chinese manufacturers utilize advanced metallurgical processes, including controlled rolling, quenching, and tempering, to achieve high yield strength—typically ranging from 400 MPa to 600 MPa. This allows designers to reduce the quantity of steel required without compromising structure safety.

- Ductility and Elongation: Modern bars meet or exceed international elongation standards, crucial in seismic zones.

- Corrosion Resistance: Integration of microalloying elements and surface treatments offers superior protection against harsh environments.

- Dimensional Precision: Automated rolling lines maintain strict tolerances, minimizing site wastage and ensuring compatibility with automated rebar processing machinery.

The table below illustrates the technical comparison among leading product standards:

| Standard | Yield Strength (MPa) | Ultimate Strength (MPa) | Elongation (%) | Corrosion Protection |

|---|---|---|---|---|

| ASTM A615 (Grade 60) | 420 | 620 | 11 | Optional Epoxy/Zinc |

| BS4449 (Grade B500B) | 500 | 600 | 5 | Microalloyed Steel |

| GB1499.2 (China HRB400E) | 400 | 570 | 16 | Alloyed + Surface Treated |

These figures demonstrate the technical competitiveness of deformed steel bars manufactured in China, frequently meeting or surpassing international requirements.

Comparison of China Deformed Steel Bars China Manufacturers and Suppliers

Choosing the right manufacturer or supplier is paramount for project reliability and cost efficiency. The Chinese market is home to diverse entities, from large vertically integrated mills to specialized exporters. Key differentiators among deformed steel bars China manufacturers and suppliers include production scale, technical expertise, quality certifications, and logistics capabilities.

| Company | Annual Capacity (MT) | Main Product Grades | Certifications | Export Regions |

|---|---|---|---|---|

| HBIS Group | 4,500,000 | HRB400E, B500B | ISO 9001, CE, ASTM | Global |

| Baosteel Engineering | 3,200,000 | HRB500E, QST Bars | ISO 14001, EN BS | Asia, Middle East |

| Jiangsu Shagang | 2,750,000 | ASTM A615, HRB400 | ISO 9001, SASO | Africa, SEA |

| Zhicheng Steel | 1,300,000 | Customized Grades | ISO 45001 | Domestic, Export |

This variety enables buyers to align product selection with specific project requirements, balancing factors such as lead time, price point, and after-sales support.

Customized Solutions and Product Offerings

The growing complexity of modern construction projects often necessitates custom-engineered rebar solutions. Chinese suppliers have invested in R&D and flexible manufacturing technologies to deliver bespoke products. Options include:

- Bespoke Diameter and Length Ranges (typically 6mm to 50mm, custom cut-to-length up to 24m)

- Enhanced Coatings: Epoxy, galvanization, anti-corrosion paint, and stainless overlays for aggressive environments

- QST (Quenching and Self-Tempering) processed bars for performance in high seismic or temperature-variant scenarios

- Integrated rebar couplers and prefabricated cages for modular and onsite assembly

- Batch traceability using QR codes and digital platforms, enhancing quality control and project documentation

These customized deformed steel bar solutions allow optimal structural performance and project economics, while also supporting sustainability initiatives through reduced material wastage and enhanced lifecycle durability.

Application Cases and Industry Impacts

The versatility of deformed steel bars is showcased in landmark projects both within China and globally. Significant application cases include:

- High-Speed Railways: Over 95% of China's 40,000-kilometer high-speed rail network uses deformed bars supplied by leading local manufacturers.

- Commercial Skyscrapers: In megacities such as Shanghai and Shenzhen, reinforced deformed steel bars ensure the structural integrity of over 300 supertall buildings.

- Infrastructure Corridors: Major bridges, tunnels, and ports under the Belt and Road Initiative rely on Chinese deformed steel bars for durability and seismic resilience.

- Overseas Mega Projects: Exported products from deformed steel bars China suppliers have supported stadium, power plant, and dam construction in more than 65 countries.

These impressive case studies underline the crucial role of China deformed steel bars, as reliable, high-performance construction materials, fostering economic growth and modernization.

Conclusion: Harnessing the Strength of Deformed Steel Bars China for Global Success

Robust supply chains, continual innovation, and proven project results have positioned deformed steel bars China as the benchmark for global construction standards. The breadth of available products—from commodity grades to specialty engineered solutions—enables architects, engineers, and developers to maximize safety, efficiency, and value at every stage. Partnering with reputable China deformed steel bars manufacturers and suppliers ensures that every project, regardless of scale, gains from cutting-edge technology, rigorous quality assurance, and reliable delivery. Now more than ever, leveraging the advantages of deformed steel bars from China is key to building the resilient, sustainable infrastructure that the future demands.

(deformed steel bars china)

FAQS on deformed steel bars china

Q: What are deformed steel bars from China?

A: Deformed steel bars China are reinforcing bars with surface ribs, widely manufactured in China. They are used to strengthen concrete structures. Their ribbed design greatly enhances bonding with concrete.Q: How can I find reliable deformed steel bars China manufacturers?

A: You can search for reputable deformed steel bars China manufacturers through B2B platforms and trade directories. Look for companies with certifications and positive customer reviews. Always request quality assurance documents.Q: What are the main advantages of sourcing deformed steel bars from China suppliers?

A: China deformed steel bars suppliers often offer competitive prices and a wide variety of products. Many provide international shipping and custom specifications. They can cater to both large and small quantity orders.Q: Are China deformed steel bars certified for international use?

A: Many deformed steel bars China manufacturers follow international quality standards like ISO and ASTM. Always verify certifications before purchasing. Request documentation to ensure compliance with your project requirements.Q: How do I request a quotation from deformed steel bars China suppliers?

A: Contact deformed steel bars China suppliers via their official websites or B2B platforms. Provide specific details like quantity, size, and grade requirements. Most suppliers respond promptly with pricing and shipping information.-

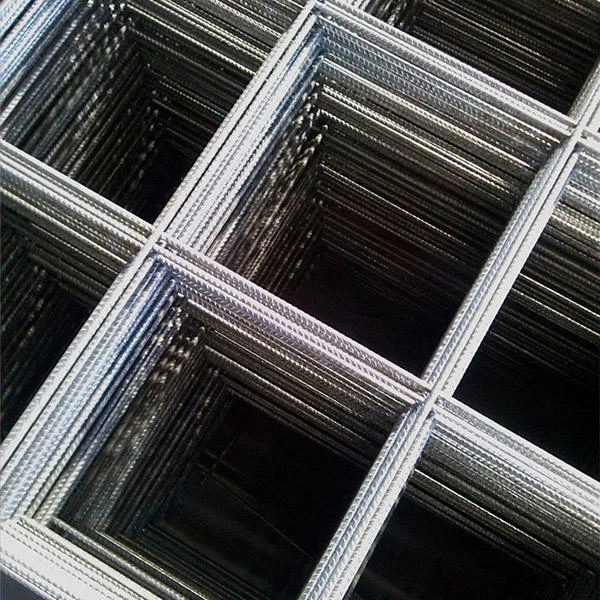

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025

-

Welded Wire Mesh for Industry | Factory Direct Supplies

NewsAug.18,2025