Oct . 12, 2024 09:30 Back to list

3x3 Galvanized Welded Wire Mesh Fence Manufacturers and Suppliers Overview

The Landscape of 3x3 Galvanized Welded Wire Mesh Fence Production

In recent years, the demand for durable, secure, and versatile fencing solutions has surged globally. One notable product that has gained prominence in this realm is the 3x3 galvanized welded wire mesh fence. With its robust structure and corrosion-resistant properties, this type of fencing is ideal for various applications, from residential to commercial and industrial settings. This article delves into the factories that produce these fences, outlining their production processes, product benefits, and market trends.

Understanding 3x3 Galvanized Welded Wire Mesh Fence

The 3x3 galvanized welded wire mesh fence features a grid pattern where each square measures 3 inches by 3 inches. Constructed from high-quality steel wire, this fence is galvanized, meaning it is coated with a protective layer of zinc to prevent rust and corrosion, ensuring a long lifespan even in challenging weather conditions. The welding process involved in manufacturing this fence enhances its strength, making it an excellent option for security and enclosure purposes.

Production Process of the Fence

The manufacturing of 3x3 galvanized welded wire mesh fences typically involves several key steps

1. Wire Drawing The process begins with wire drawing, where high-quality steel is drawn into thin wires. This is a crucial step as the diameter of the wire affects the overall strength and characteristics of the final product.

2. Welding Once the wires are prepared, they are arranged in a grid format and welded together at the junctions. The welding technique ensures that each intersection is strong, providing the structural integrity necessary for the fence.

3. Galvanization After welding, the mesh is subjected to galvanization. This can be done through hot-dip galvanization or electro-galvanization processes. Hot-dip galvanization is more common for its ability to form a thicker and more durable zinc coating.

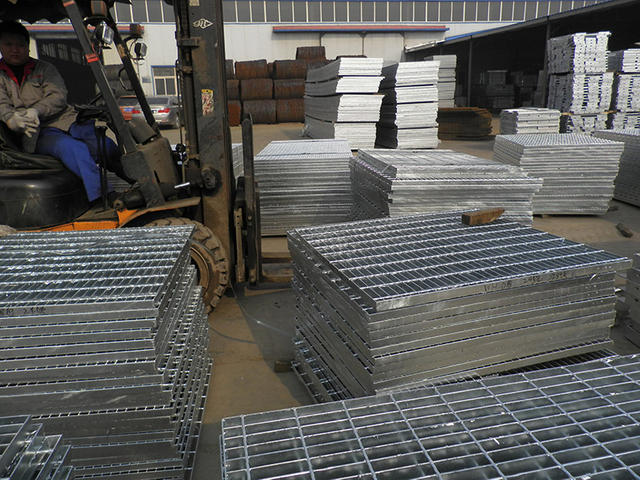

4. Cutting and Packaging The finished wire mesh is then cut to specifications and packaged for distribution. Factories often have quality control measures in place to ensure that each batch meets industry standards.

Benefits of Galvanized Welded Wire Mesh Fences

The popularity of 3x3 galvanized welded wire mesh fences can be attributed to numerous benefits

3x3 galvanized welded wire mesh fence factories

- Durability Due to the galvanization process, the fence is resistant to rust and corrosion, making it suitable for outdoor use.

- Security The robust design provides an effective barrier against intruders, making it a preferred choice for residential and commercial properties.

- Versatility This type of fencing can be used in a wide array of applications, including farms, construction sites, parks, and residential yards.

- Cost-Effectiveness While initially, it may seem more expensive than other types of fencing, its longevity and minimal maintenance requirements can lead to cost savings over time.

- Aesthetic Appeal Available in various colors and finishes, these fences can be tailored to suit the aesthetic needs of different properties.

Market Trends and Forecast

The market for 3x3 galvanized welded wire mesh fences is expected to witness significant growth in the coming years. Factors such as urbanization, population growth, and increasing awareness about security will drive demand. Additionally, advancements in manufacturing technologies and strict regulations regarding fencing solutions will further contribute to market expansion.

Countries experiencing rapid infrastructure development, coupled with a rise in commercial establishments, are likely to see an increase in the use of welded wire mesh fences. Emerging markets in Asia-Pacific and Africa stand out as particularly promising areas for manufacturing factories, driven by both domestic demand and export potential.

Global Factory Landscape

As the demand for 3x3 galvanized welded wire mesh fences rises, numerous factories globally have emerged to meet this need. These factories leverage modern production techniques and employ skilled labor to ensure high-quality output. Many suppliers are also focusing on sustainability, using eco-friendly practices in their manufacturing processes.

In conclusion, the 3x3 galvanized welded wire mesh fence represents a blend of durability, security, and versatility. With the backing of advanced manufacturing processes and a growing market, these fences are set to remain a popular choice for a wide range of applications. As consumers continue to prioritize safety and aesthetics, the factories producing this vital product will play an essential role in meeting the ever-evolving demands of the marketplace. As the industry moves forward, innovation and quality assurance will be key drivers in establishing a competitive edge in a bustling marketplace.

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025