Dec . 20, 2024 17:35 Back to list

Black Nail Wire Production and Supply by Leading Manufacturers in the Industry

The Rise of Black Nail Wire Manufacturers A Comprehensive Overview

In the realm of manufacturing and construction, the significance of high-quality materials cannot be overstated. Among these, black nail wire has emerged as a vital component in various applications. Black nail wire, known for its durability and strength, is primarily used in the production of nails, staples, and other fasteners. As industries evolve and the demand for reliable materials increases, black nail wire manufacturers are carving out a niche in the global market.

What is Black Nail Wire?

Black nail wire is a type of steel wire that has been coated with a black oxide to provide increased resistance to corrosion. This coating not only enhances the physical appearance of the wire but also improves its performance in various conditions. The wire is usually produced with high-carbon steel, which grants it the strength necessary to withstand significant tensile stress. This makes it an ideal choice for making nails that require robust holding power in construction and woodworking tasks.

The Manufacturing Process

The production of black nail wire involves several critical steps. First, raw steel is drawn down to the desired diameter using precision drawing equipment. This process, known as wire drawing, is crucial as it affects the wire's final strength and flexibility. Once the wire is drawn to size, it undergoes a heat treatment process. This helps to increase its tensile strength and durability, making it more suitable for heavy-duty applications.

After heat treatment, the wire is subjected to a blackening process, which typically involves immersing it in a chemical solution that creates a black oxide layer. This layer serves multiple purposes it protects the wire from rust, enhances its aesthetic appeal, and provides better grip for fasteners during use.

The Role of Manufacturers

Black nail wire manufacturers play an integral role in ensuring the availability and quality of this essential material. These companies often focus on innovation and sustainability, striving to reduce their environmental footprint while meeting industry standards. Many manufacturers are now investing in advanced technologies and processes that allow for the production of high-quality wire with less waste.

black nail wire manufacturer

Moreover, competitive manufacturers are also focusing on customer service and responsiveness. In today’s fast-paced market, the ability to deliver products promptly and efficiently is a key differentiator. Customization is also becoming increasingly important, as clients seek specific dimensions and grades of black nail wire to suit their unique project requirements.

Applications of Black Nail Wire

The applications of black nail wire are diverse and expansive. In the construction industry, it is predominantly used to create various types of nails, including framing nails, roofing nails, and finishing nails. These nails are pivotal in securing materials together, ensuring structural integrity in buildings and other constructions.

In addition to construction, black nail wire finds application in the manufacturing of furniture, where it is used in creating staples and fasteners that hold joints together. Its corrosion-resistant properties also make it suitable for outdoor furniture and structures exposed to harsh weather conditions.

Market Trends and Challenges

The market for black nail wire is influenced by several factors, including the overall growth of the construction industry, advancements in manufacturing technology, and shifts in consumer preferences toward sustainable products. However, manufacturers face challenges such as fluctuating raw material costs, which can impact pricing and profitability.

Moreover, competition in the global market is intensifying, with numerous players striving to gain a foothold. This competition drives innovation but can also lead to price wars, affecting smaller manufacturers who may struggle to keep up with larger companies.

Conclusion

In summary, black nail wire manufacturers are vital players in the construction and manufacturing industries. By focusing on quality, innovation, and customer satisfaction, these manufacturers contribute significantly to the production of durable and reliable fasteners. As the demand for high-quality construction materials continues to rise, the role of black nail wire and its manufacturers will only become more critical. In this dynamic market, staying abreast of trends and challenges will be key for manufacturers aiming to maintain their competitive edge.

-

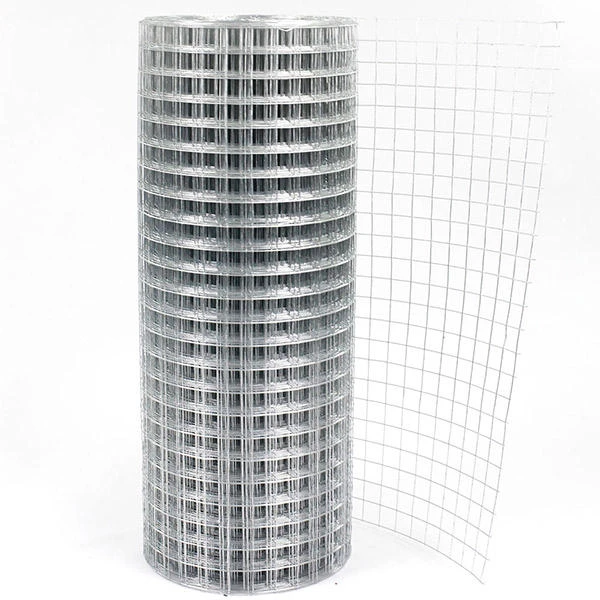

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025