Dec . 23, 2024 21:01 Back to list

Innovative Uses and Benefits of Black Annealed Iron Wire in Various Applications

The Versatility and Applications of Black Annealed Iron Wire

Black annealed iron wire, a material recognized for its unique properties and various industrial applications, has long been utilized in construction, agriculture, and manufacturing sectors. This article delves into the characteristics, production processes, and diverse applications of black annealed iron wire, highlighting its essential role in modern industrial practices.

Characteristics of Black Annealed Iron Wire

Black annealed iron wire is characterized by its dark surface color, which results from the manufacturing process involving annealing—a heat treatment that softens the wire and enhances its ductility. This unique treatment alleviates internal stresses, making the wire more pliable and easier to work with. The wire typically has a tensile strength ranging from low to medium, allowing it to bend without breaking while providing adequate strength for various applications.

Another significant characteristic of black annealed iron wire is its corrosion resistance. Although it is not galvanized, the annealing process gives it a protective layer that helps mitigate the risk of rust when used under certain conditions. However, it is important to understand that black annealed wire is best suited for applications where exposure to moisture is minimal, as it may not withstand harsh environmental conditions as effectively as coated wires.

Production Process

The production of black annealed iron wire begins with drawing iron wire through different gauge sizes to achieve the desired diameter. The wire is then subjected to an annealing process, which involves heating it in a controlled atmosphere and then cooling it gradually. This step is crucial as it reduces hardness, increases ductility, and enhances the wire’s overall mechanical properties.

The final product is typically available in various gauges and lengths, catering to the specific needs of users. The wire can be produced in coils or straightened and cut to specific lengths, depending on its intended application.

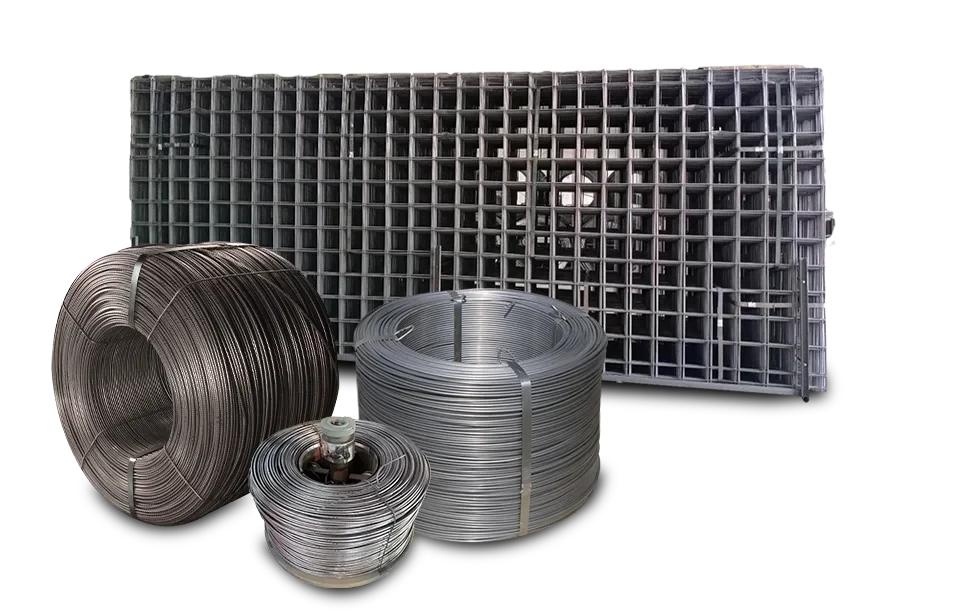

black annealed iron wire

Diverse Applications

1. Construction One of the primary applications of black annealed iron wire is in the construction industry. It is often used to tie rebar in concrete structures, providing additional support and ensuring the integrity of the building. Its flexibility allows for easy manipulation and secure binding, which is essential in reinforcement tasks.

2. Agriculture Farmers utilize black annealed wire for a variety of purposes, including fencing, trellises for climbing plants, and securing crops. Its durability and resistance to bending make it an ideal choice for creating strong and reliable boundaries, protecting livestock, and supporting vine growth.

3. Manufacturing In the manufacturing sector, black annealed wire is employed in making various products such as springs, mesh, and wire forms. Its ability to withstand deformation while returning to its original shape makes it suitable for applications requiring resilience and flexibility.

4. Craft and DIY Projects The wire’s easy-to-bend nature makes it a popular choice among crafters and DIY enthusiasts. Whether for creating decorative items, sculptures, or homemade jewelry, black annealed iron wire proves to be a versatile material that can be shaped into numerous forms.

5. Electrical Applications Some forms of black annealed iron wire are used in electrical applications, particularly in making connectors and grounding systems. Its conductivity, combined with its mechanical properties, ensures reliability in electrical systems.

Conclusion

Black annealed iron wire serves as a testament to the fusion of functionality and versatility in industrial materials. Its unique properties, combined with a wide range of applications, make it an indispensable tool across various sectors. As industries continue to evolve, the demand for reliable and adaptable materials like black annealed iron wire is likely to grow, ensuring that it remains a fundamental component of modern manufacturing, construction, and agricultural practices.

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025