Nov . 19, 2024 10:45 Back to list

30m Roll of BWG22 Galvanized Welded Wire Mesh from Leading Manufacturers

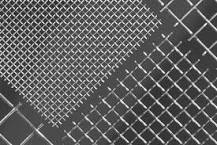

Exploring BWG22 Galvanized Welded Wire Mesh Key Features and Manufacturing Insights

Galvanized welded wire mesh has become a staple in various industries due to its versatility, durability, and cost-effectiveness. Among the many specifications available in the market, BWG22 galvanized welded wire mesh stands out for its unique characteristics and benefits. This article delves into the features, applications, and manufacturing insights pertaining to BWG22 galvanized welded wire mesh available in 30-meter rolls.

Understanding Wire Gauge and Specifications

BWG, or Birmingham Wire Gauge, is a standardized wire gauge system that quantifies the thickness of wire. A BWG22 wire measures approximately 0.025 inches (0.64 mm) in diameter. This thickness strikes a perfect balance between strength and flexibility, making BWG22 a popular choice for various applications requiring structural integrity and moderate load-bearing capacity.

Galvanization adds another layer of protection to the wire mesh. The process involves coating the steel wire with a layer of zinc to prevent rust and extend the lifespan of the product. This protective layer is essential, particularly in outdoor or humid conditions, ensuring that the mesh can withstand environmental challenges while maintaining its structural integrity.

Applications of BWG22 Galvanized Welded Wire Mesh

BWG22 galvanized welded wire mesh is employed across a multitude of sectors. Here are some primary applications

1. Construction and Building This wire mesh is commonly used in construction for reinforcing concrete slabs, foundations, and walls. Its robust design helps in distributing loads effectively and enhancing the structural integrity of buildings.

2. Agriculture Farmers utilize BWG22 mesh for fencing livestock and protecting crops from wildlife. The durability and resistance to corrosion make it ideal for outdoor environments where exposure to moisture and soil is constant.

3. Home Improvement Projects DIY enthusiasts often incorporate galvanized welded wire mesh in various home improvement projects, such as creating garden fences, animal enclosures, and decorative structures. Its aesthetic appeal combined with strength makes it a viable option for various applications at home.

bwg22 galvanized welded wire mesh 30m roll manufacturers

4. Industrial Uses In industrial settings, this type of mesh is utilized for safety barriers, machine guards, and storage racks, offering enhanced safety and efficiency in workplace environments.

5. Municipal Applications BWG22 welded wire mesh is also used in municipal applications, including security fencing for parks, schools, and public spaces, providing visibility while ensuring safety.

Manufacturing Process

The manufacturing of BWG22 galvanized welded wire mesh involves several stages, each requiring precision and quality control to ensure the final product meets industry standards. Here’s a brief rundown of the manufacturing process

1. Wire Drawing High-quality steel rods are drawn through a series of dies to achieve the desired wire gauge (BWG22 in this case). This process enhances the tensile strength of the wire.

2. Welding The drawn wire is then formed into a mesh pattern using automated welding machines. This step involves crossing horizontal and vertical wires at pre-determined intervals and welding them at the intersections. The welding process must be carried out meticulously to ensure even and strong connections.

3. Galvanization After welding, the mesh is subjected to galvanization. This can be done through hot-dip galvanizing, where the welded mesh is submerged in molten zinc, or through electro-galvanizing. Hot-dip galvanization typically provides thicker and more durable coatings, while electro-galvanization offers a smoother finish.

4. Cutting and Packaging Once galvanized, the mesh is cut into specified sizes, commonly 30-meter rolls for convenience, and is then packaged for distribution.

Conclusion

BWG22 galvanized welded wire mesh is not just a product; it's a versatile solution that meets a diverse range of needs across industries. Its balance of strength and flexibility, along with the protective benefits of galvanization, makes it an ideal choice for construction, agriculture, and beyond. Manufacturers focused on producing high-quality wire mesh can ensure the longevity and reliability of their products, satisfying the growing demand in both commercial and residential markets. Whether for reinforcing structures or securing livestock, BWG22 galvanized welded wire mesh continues to be a trusted option for professionals and DIYers alike.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025