Dec . 18, 2024 19:58 Back to list

3x3 galvanized welded wire mesh fence factories

The Importance of 3x3 Galvanized Welded Wire Mesh Fence Factories

In the modern construction and agricultural industries, the demand for durable and reliable fencing solutions has surged. Among the various options available, 3x3 galvanized welded wire mesh fences have emerged as a popular choice. This article delves into the significance of these fences and the role that specialized factories play in their production.

What is 3x3 Galvanized Welded Wire Mesh?

The term 3x3 refers to the 3-inch spacing between the vertical and horizontal wires in the mesh, and galvanized indicates that the wire has been coated with a layer of zinc to prevent rusting and corrosion. This combination creates a robust and long-lasting fencing solution that is ideal for various applications, including residential, commercial, and agricultural settings. The welded design adds structural integrity, making it resistant to warping, bending, and breaking under stress.

Applications of 3x3 Galvanized Welded Wire Mesh Fences

1. Agricultural Use Farmers frequently use galvanized welded wire mesh fences to protect livestock and crops from predators. The fence serves as a physical barrier that discourages animals from entering specific areas, thus maintaining the health and safety of the farm.

2. Commercial Fencing Businesses utilize these fences for security purposes. They can be installed around warehouses, construction sites, and commercial properties to deter trespassing and potential theft. The visibility of a welded wire fence also allows for easy monitoring of the premises.

3. Residential Enclosures Homeowners appreciate the aesthetic and functional benefits of 3x3 welded wire mesh fences in gardens and backyards. They provide a way to delineate property boundaries while maintaining an open feel that allows for visibility and light.

The Role of Factories in Producing Quality Fences

3x3 galvanized welded wire mesh fence factories

The production of 3x3 galvanized welded wire mesh fences is a specialized process that requires expertise and advanced machinery. Factories that focus on this type of fencing are equipped with state-of-the-art technology to ensure the highest quality standards. Here are several key aspects of what these factories do

1. Material Selection Quality begins with the selection of raw materials. Factories source high-grade steel wire that meets industry standards, ensuring that the final product will have the strength and durability needed for effective fencing.

2. Galvanization Process A crucial step in the production is the galvanization of the wire. This process protects against rust and prolongs the lifespan of the fence. Factories utilize hot-dip galvanization techniques to ensure that every inch of the wire is adequately coated.

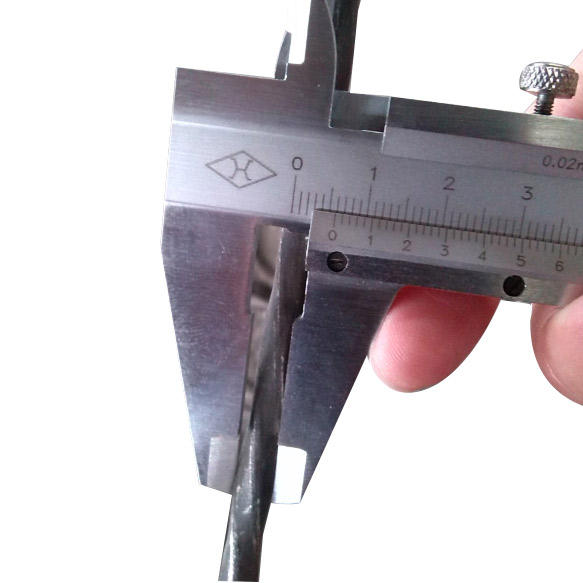

3. Precision Welding Using advanced welding techniques, factories ensure that the wires are securely bonded together at all intersections. This not only provides additional strength but also enhances the safety and stability of the fence.

4. Quality Control Reputable factories implement strict quality control measures throughout the manufacturing process. Each batch is tested for strength, durability, and compliance with safety standards before being shipped to customers.

5. Customization and Flexibility Many factories offer customizable options, allowing clients to specify dimensions, coatings, and even colors. This flexibility caters to a diverse range of needs across various industries.

Conclusion

In summary, 3x3 galvanized welded wire mesh fences serve multiple purposes and have become an indispensable resource in agricultural, commercial, and residential applications. The factories dedicated to producing these fences play a crucial role in ensuring that the products meet high-quality standards, providing customers with reliable and effective fencing solutions. As demand grows, these factories are poised to innovate and adapt, further enhancing the value of their products in an ever-evolving market.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025