máj . 13, 2025 10:55 Späť na zoznam

Weld Wire Mesh: Durable, Versatile Solutions for Industrial and Structural Applications

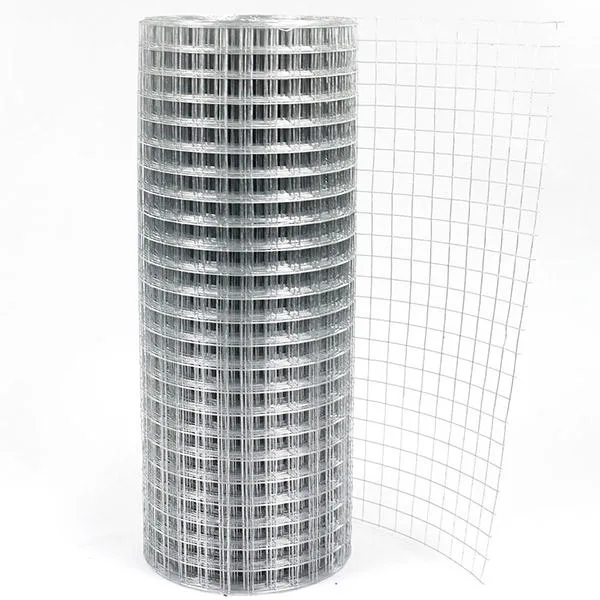

Weld wire mesh, also known as welded wire mesh, is one of the most widely used and cost-effective reinforcement and fencing materials in the world. Its strength, versatility, and ease of installation make it suitable for both structural concrete reinforcement and a wide range of industrial and commercial applications.

Whether you’re sourcing BRC welded wire mesh for concrete slabs, PVC zvárané drôtené pletivo for fencing, or general zvárané drôtené pletivo pre priemysel, this guide will walk you through types, uses, and what to look for when buying.

What Is Weld Wire Mesh?

Weld wire mesh is a grid of intersecting steel wires that are welded together at each junction. The welding creates a rigid structure that maintains its shape under stress, making it ideal for reinforcement, containment, and barrier applications.

Key features:

Available in square or rectangular grid patterns

Wire diameters typically range from 1 mm to 12 mm

Supplied in flat sheets or rolls

Options for galvanized, black (plain), or PVC-coated finishes

This mesh is used across construction, agriculture, fencing, mining, and manufacturing industries.

Types of Welded Wire Mesh

BRC Welded Wire Mesh

BRC welded wire mesh refers to prefabricated steel mesh panels used for reinforcing concrete structures. It gets its name from British Reinforcement Company (BRC), a widely recognized format in the construction industry.

Vlastnosti:

Produced according to BS 4483 standards

Common types: A142, A193, A252, A393, etc.

Used in slab reinforcement, beams, walls, and foundations

High yield strength (≥ 500 MPa)

BRC mesh is valued for its uniformity, compliance with building codes, and quick installation — helping reduce construction time and labor.

PVC Welded Wire Mesh

PVC zvárané drôtené pletivo is steel wire mesh coated with polyvinyl chloride (PVC), offering improved corrosion resistance, weatherproofing, and aesthetics.

Ideal for:

Fencing for gardens, schools, and sports fields

Animal cages and enclosures

Decorative or protective barriers

Coastal or high-moisture environments

PVC coating not only protects the steel from rust but also adds color (usually green or black) and a smoother finish, making it safer and more attractive for public or residential use.

Galvanized Welded Wire Mesh

Hot-dip or electro-galvanized welded mesh is commonly used in both industrial and residential settings for durability and rust protection.

Applications include:

Machine safety guards

Partitions

Poultry netting

Concrete reinforcement (light-duty)

HVAC duct mesh

Welded Wire Mesh for Industry: Broad Applications

Welded wire mesh for industry plays a key role in:

Construction – concrete slabs, retaining walls, tunnels

Manufacturing – machine guards, racks, screens

Agriculture – fencing, crop protection, livestock enclosures

Mining – screening, safety barriers, ground support

Energy – reinforcement for wind turbine bases and power plants

Transportation – infrastructure reinforcement, sound barriers

Its strength, stability, and adaptability make it one of the most reliable materials in industrial construction and safety systems.

Specifications to Consider

When buying welded wire mesh, key parameters include:

|

Špecifikácia |

Typical Range |

|

Priemer drôtu |

1 mm – 12 mm |

|

Veľkosť oka |

25 x 25 mm up to 200 x 200 mm (custom options too) |

|

Sheet Size |

2.1 x 5.0 m (standard) or custom sizes |

|

Rolls |

Up to 30 meters long, especially for fencing mesh |

|

Coating Options |

Galvanized, PVC-coated, black (uncoated) |

|

Standards |

ASTM A1064, BS 4483, ISO 10692, etc. |

Choosing a Weld Wire Mesh Supplier

When sourcing weld wire mesh, especially for bulk or industrial use, ensure your supplier provides:

Verified steel grades and tensile strength

Consistent weld quality at intersections

Full documentation (COA, mill test certificate)

Compliance with regional standards

Customization capabilities (cutting, bending, coating)

Whether you’re working with a BRC welded wire mesh manufacturer or a general zvárané drôtené pletivo pre priemysel supplier, direct communication and technical support are key to getting the right product for your project.

Bulk Packaging & Delivery

Most welded mesh is delivered in:

Flat steel pallets (for panels)

Rolls wrapped in plastic or shrink wrap (for flexible mesh)

Container loads (for international shipping)

Consider the following:

Will mesh be stored outdoors? Choose galvanized or PVC-coated.

Do you need to bend or cut mesh on-site? Request pre-cut or pre-shaped panels.

Is crane access available? Confirm packaging and unloading support.

Weld Wire Mesh FAQs

Q1: What’s the difference between BRC mesh and standard welded mesh?

A: BRC mesh refers to high-strength steel mesh used specifically for concrete reinforcement. It’s standardized and tested for structural use, while general welded mesh may not meet structural load requirements.

Q2: Can PVC welded wire mesh be used for security fences?

A: Yes, it’s suitable for low to medium-security fencing. For high-security applications, tighter mesh spacing and thicker wire are recommended.

Q3: Is welded wire mesh better than woven wire mesh?

A: Welded mesh is stronger and more rigid, making it better for structural and industrial applications. Woven mesh is more flexible and suited for filtration or light-duty screens.

Q4: How long does PVC welded mesh last?

A: With proper installation and environmental care, it can last 10–20 years, depending on the quality of the PVC coating and exposure.

Q5: Can I order custom-sized mesh panels?

A: Yes. Many factories offer cut-to-size or bent mesh panels for specific project requirements.

Whether you're reinforcing a concrete slab, fencing a property, or designing custom industrial barriers, weld wire mesh is a proven solution for strength, flexibility, and durability. From BRC welded wire mesh for structural builds to weather-resistant PVC zvárané drôtené pletivo for fencing and enclosures, there’s a product tailored to every need.

-

Versatile Black Annealed Binding Wire The Ultimate Solution

SprávyJun.26,2025

-

Ultimate Chain Link Fence Solution Durable Versatile

SprávyJun.26,2025

-

Superior Twisted Square Bar Construction Reinforcement Solution

SprávyJun.26,2025

-

Ssential Reinforcing Mesh For Modern Construction Projects

SprávyJun.26,2025

-

Precision Engineered Cold Drawn Wire For Heavy Industry

SprávyJun.26,2025

-

High Strength Welded Wire Mesh Project Must Have

SprávyJun.26,2025