feb . 16, 2025 09:18 Back to list

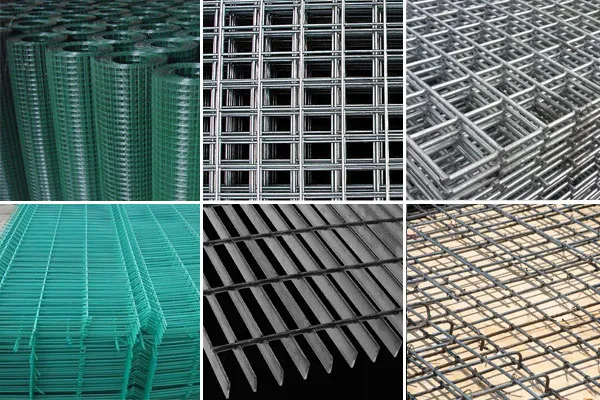

diamond steel grating factories

Hot-dipped galvanized steel grating is a highly sought-after component in various industrial and commercial applications due to its robustness and versatility. With over a decade of experience in the steel industry, I have had the privilege of working closely with numerous manufacturers and suppliers to understand the intrinsic benefits and quality determinants of this essential product.

Authoritativeness in the field of steel grating production is often linked to the producer’s commitment to innovation and continuous improvement. Leading OEM providers engage in rigorous product testing and actively pursue certifications from reputable standards organizations. This commitment not only underscores their authority in the field but also provides customers with the assurance that they are investing in a premium product. Furthermore, reputable producers often partake in industry conferences and trade shows, sharing valuable insights and staying abreast of emerging trends and technologies. Trustworthiness is perhaps the most crucial element when choosing a supplier for hot-dipped galvanized steel grating. Trust is built through transparency, reliability, and stellar customer service. OEM producers who provide detailed product information, including material specifications and galvanization techniques, enable customers to make informed purchasing decisions. Additionally, reliable providers offer extensive after-sales support, addressing any concerns and ensuring customer satisfaction. Establishing long-term partnerships with suppliers who consistently deliver high-quality products fosters trust and reliability. In conclusion, the selection of an OEM producer for hot-dipped galvanized steel grating should be informed by a thorough understanding of their experience, expertise, authoritativeness, and trustworthiness. By prioritizing these attributes, businesses can secure steel grating solutions that not only meet their specific needs but also stand the test of time, offering superior performance and resilience in all applications.

Authoritativeness in the field of steel grating production is often linked to the producer’s commitment to innovation and continuous improvement. Leading OEM providers engage in rigorous product testing and actively pursue certifications from reputable standards organizations. This commitment not only underscores their authority in the field but also provides customers with the assurance that they are investing in a premium product. Furthermore, reputable producers often partake in industry conferences and trade shows, sharing valuable insights and staying abreast of emerging trends and technologies. Trustworthiness is perhaps the most crucial element when choosing a supplier for hot-dipped galvanized steel grating. Trust is built through transparency, reliability, and stellar customer service. OEM producers who provide detailed product information, including material specifications and galvanization techniques, enable customers to make informed purchasing decisions. Additionally, reliable providers offer extensive after-sales support, addressing any concerns and ensuring customer satisfaction. Establishing long-term partnerships with suppliers who consistently deliver high-quality products fosters trust and reliability. In conclusion, the selection of an OEM producer for hot-dipped galvanized steel grating should be informed by a thorough understanding of their experience, expertise, authoritativeness, and trustworthiness. By prioritizing these attributes, businesses can secure steel grating solutions that not only meet their specific needs but also stand the test of time, offering superior performance and resilience in all applications.

Next:

Latest news

-

Black Annealed Wire Specification - High Quality & Custom Options from Leading Factories, Suppliers, Manufacturers

NewsJun.10,2025

-

High-Quality 18 Gauge Black Steel Wire Reliable Factories & Suppliers

NewsJun.10,2025

-

Chain Link Fence Gates - Durable & Secure Access Solutions

NewsJun.10,2025

-

Premium Cold Rolled Steel Bar Supplier High Strength & Precision

NewsJun.10,2025

-

Galvanized Wire Brick Force Mesh - Corrosion Resistant

NewsJun.09,2025

-

Galvanized Metal Wire for Construction Strong & Corrosion-Resistant

NewsJun.09,2025