feb . 15, 2025 15:47 Back to list

Cold Drawn Wire

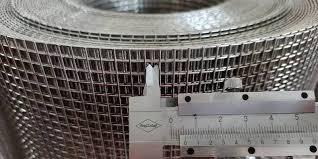

OEM building welded mesh products have become increasingly significant in the construction and infrastructure industries. Their versatility and customization options make them a favored choice for numerous projects ranging from residential to commercial, and industrial applications. Seamlessly integrating strength with flexibility, welded meshes provide solutions to various structural needs while ensuring safety and durability over time.

Trustworthiness in this sector is further established through third-party testing and verification. Independent bodies are often called to examine the products' quality before deployment. These tests assess various performance metrics, including tensile strength, resistance to environmental factors, and overall durability. When manufacturers willingly engage in this level of scrutiny, it sends a strong message to clients about their confidence in their products. Incorporating real-world experiences into the development of OEM welded mesh solutions enriches the product catalog with innovations tailored to meet specific challenges faced by clients. Feedback from previous projects offers invaluable insights, prompting manufacturers to improve or adjust their offerings. This continuous improvement loop not only meets current demands but anticipates future needs, positioning manufacturers as leaders in the industry. For construction companies and architects, the advantage of using OEM building welded mesh is also financially appealing. Custom products mean reduced waste, as the meshes are pre-sized and shaped to precise specifications. This efficiency translates to cost savings, enabling projects to stay within budget while maintaining high standards of structural integrity. Furthermore, in a world increasingly focused on sustainability, welded mesh products offer eco-friendly solutions. Recycled steel is commonly used in mesh production, reducing the need for new raw material while still maintaining high quality. This practice not only lessens the environmental impact but also aligns with the sustainability goals of conscientious builders. In conclusion, the realm of OEM building welded mesh is underscored by a dedication to innovation, quality, and client satisfaction. Through expertise in material selection, authority in manufacturing processes, and a commitment to trustworthy practices, these products offer a reliable, versatile, and sustainable solution for modern construction challenges. As the industry continues to evolve, so too will the integration of advanced technologies and sustainable practices in welded mesh production, ensuring they remain at the forefront of construction materials for years to come.

Trustworthiness in this sector is further established through third-party testing and verification. Independent bodies are often called to examine the products' quality before deployment. These tests assess various performance metrics, including tensile strength, resistance to environmental factors, and overall durability. When manufacturers willingly engage in this level of scrutiny, it sends a strong message to clients about their confidence in their products. Incorporating real-world experiences into the development of OEM welded mesh solutions enriches the product catalog with innovations tailored to meet specific challenges faced by clients. Feedback from previous projects offers invaluable insights, prompting manufacturers to improve or adjust their offerings. This continuous improvement loop not only meets current demands but anticipates future needs, positioning manufacturers as leaders in the industry. For construction companies and architects, the advantage of using OEM building welded mesh is also financially appealing. Custom products mean reduced waste, as the meshes are pre-sized and shaped to precise specifications. This efficiency translates to cost savings, enabling projects to stay within budget while maintaining high standards of structural integrity. Furthermore, in a world increasingly focused on sustainability, welded mesh products offer eco-friendly solutions. Recycled steel is commonly used in mesh production, reducing the need for new raw material while still maintaining high quality. This practice not only lessens the environmental impact but also aligns with the sustainability goals of conscientious builders. In conclusion, the realm of OEM building welded mesh is underscored by a dedication to innovation, quality, and client satisfaction. Through expertise in material selection, authority in manufacturing processes, and a commitment to trustworthy practices, these products offer a reliable, versatile, and sustainable solution for modern construction challenges. As the industry continues to evolve, so too will the integration of advanced technologies and sustainable practices in welded mesh production, ensuring they remain at the forefront of construction materials for years to come.

Next:

Latest news

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025