sep . 06, 2024 09:02 Back to list

Galvanized Metal Wire for Construction | Durable & High-Quality Solutions

Galvanized Metal Wire for Construction A Durable Solution

Galvanized metal wire has become an essential component in the construction industry, serving numerous applications that require strength, durability, and resistance to corrosion. The process of galvanization involves coating steel wire with a layer of zinc, which acts as a barrier against rust and other environmental factors. This protective coating ensures that galvanized wire maintains its integrity even in harsh conditions, making it a preferred choice for various construction projects.

One of the primary advantages of galvanized metal wire is its excellent corrosion resistance. Unlike untreated steel, which can rapidly oxidize when exposed to moisture and air, galvanized wire can withstand these elements for an extended period. This quality is particularly important in areas where construction materials may be exposed to rain, humidity, or chemical exposures, such as coastal regions and industrial sites. By utilizing galvanized wire, contractors can reduce maintenance costs and extend the lifespan of structures significantly.

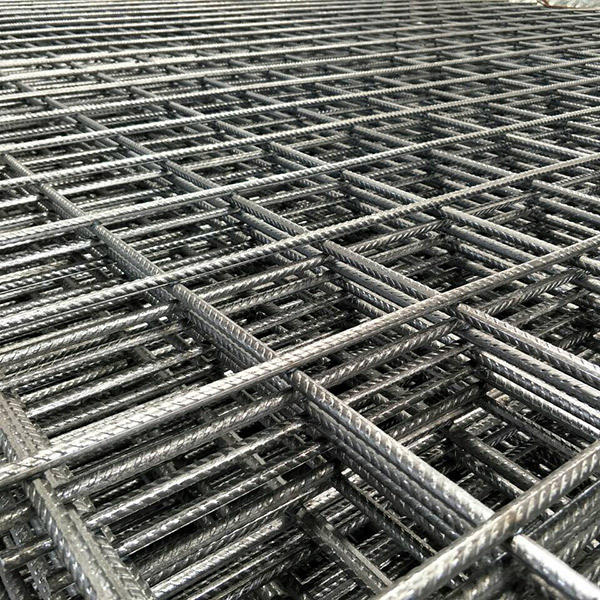

Another benefit of galvanized metal wire is its versatility. It is available in various gauges and strengths, making it suitable for a wide range of applications. For instance, heavy-gauge galvanized wire is often used for constructing fences, while lighter gauges may be employed in applications such as tying rebar in concrete work or securing insulation. This versatility allows builders and engineers to choose the right type of wire for the specific demands of their projects, ensuring safety and structural integrity.

galvanized metal wire for construction factory

Galvanized wire is also a cost-effective solution. While the initial investment may be slightly higher than that of untreated wire, the long-term savings associated with reduced maintenance and replacement costs make it a valuable choice for builders. Moreover, the longevity of galvanized wire means that structures can remain intact for years without the need for immediate repairs, thereby enhancing overall project efficiency.

In addition to its practical benefits, galvanized metal wire is also environmentally friendly. While the galvanization process does involve the use of zinc, it ultimately prolongs the life of the wire and reduces waste. As such, construction projects utilizing this material contribute to sustainability efforts by minimizing the need for frequent replacements and repairs.

The manufacturing process for galvanized metal wire typically involves drawing steel wire and then immersing it in molten zinc, which adheres to the surface. This method not only ensures a sturdy coating but also allows for a wide range of finishes, from smooth to coarse, depending on the intended use. Manufacturers can tailor the properties of galvanized wire to meet specific requirements, enhancing its functionality across various applications.

In conclusion, galvanized metal wire stands out as a reliable and efficient choice for construction applications. With its exceptional resistance to corrosion, versatility in use, and cost-effective nature, it is no wonder that builders and contractors around the world increasingly prefer this material. As the construction industry continues to evolve, the adoption of galvanized wire will likely increase, reinforcing its status as a crucial component in modern construction practices. By investing in galvanized metal wire, stakeholders can ensure safety, durability, and long-lasting results for their projects, thereby contributing to a more robust infrastructure for future generations.

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025