Dec . 29, 2024 07:33 Back to list

reinforcing mesh for industrial manufacturers

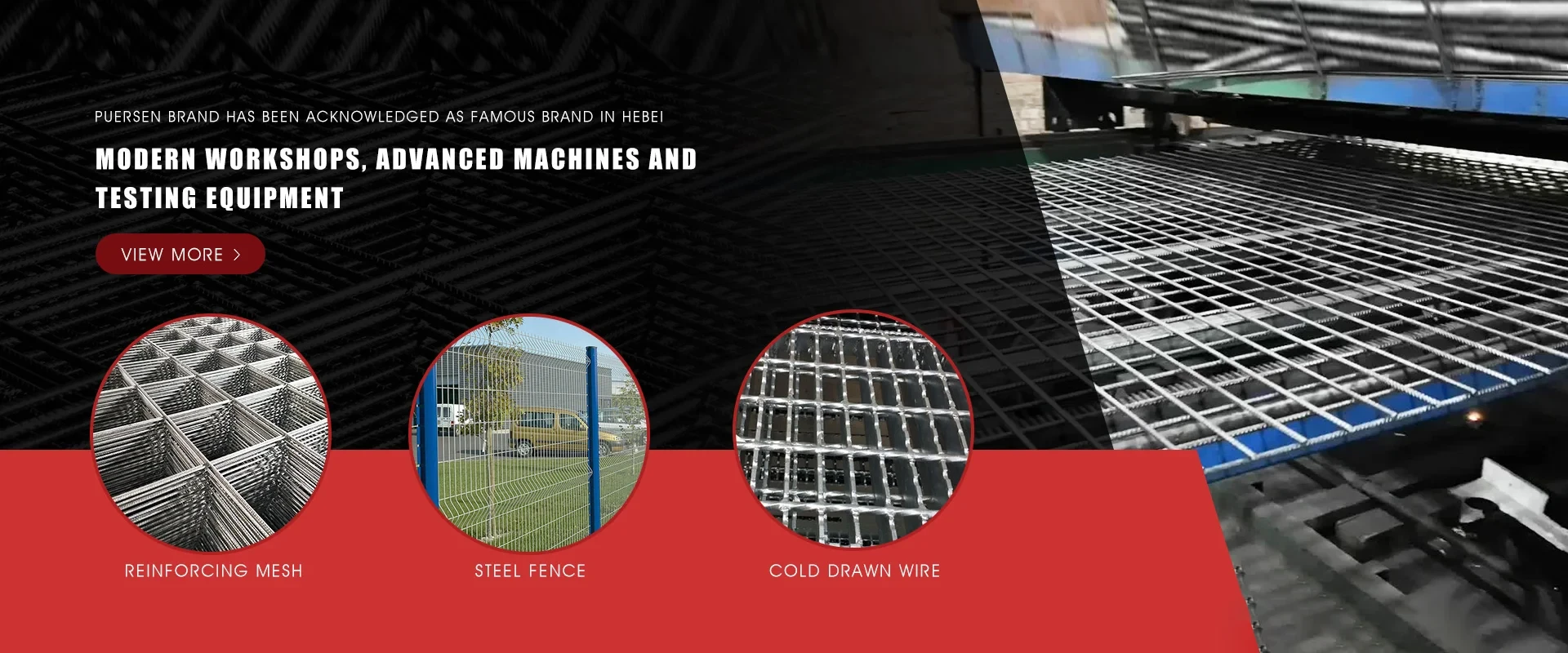

Reinforcing Mesh for Industrial Manufacturers

Reinforcing mesh, commonly known as reinforcement mesh or welded wire mesh, plays a critical role in the industrial manufacturing sector. With the continuously growing demands for robust and reliable construction materials, reinforcing mesh has emerged as a vital component in ensuring structural integrity and durability. This article explores the significance of reinforcing mesh in industrial applications, its composition, manufacturing processes, and benefits to manufacturers.

Understanding Reinforcing Mesh

Reinforcing mesh is a grid-like structure made of high-quality steel wires arranged in a series of rows and columns, which are welded at their intersections. This mesh is designed to provide strength and support to concrete structures, enhancing their performance and longevity. It serves as a crucial reinforcement element in various applications, including slabs, beams, and walls in both residential and industrial buildings.

Composition and Types

Reinforcing mesh is typically composed of low-carbon steel wires, which offer an excellent balance of strength and ductility. The wires can vary in diameter and spacing, depending on the specific requirements of a project. There are several types of reinforcing mesh, including

1. Welded Wire Mesh This is the most commonly used type, where wires are welded at their intersections to form a rigid grid. It is available in various mesh sizes and wire diameters.

2. Bar Mats These consist of steel reinforcement bars arranged in a grid pattern. Bar mats offer increased load-bearing capacity and are often used in heavy-duty applications.

3. Stainless Steel Mesh Used in environments where corrosion resistance is essential, such as coastal areas or chemical plants, stainless steel mesh provides both durability and aesthetics.

Manufacturers select the type of reinforcing mesh based on factors such as load requirements, environmental conditions, and specific project specifications.

Manufacturing Process

The production of reinforcing mesh involves several steps

1. Wire Drawing Steel rods are drawn through a series of dies to create wires of required thickness.

reinforcing mesh for industrial manufacturers

2. Welding The cut wires are arranged in a grid pattern and welded at the intersections using automated welding machines, ensuring uniform strength.

3. Inspection and Testing Quality control measures are implemented to check for defects and ensure adherence to industry standards.

4. Coating and Finishing Depending on the application, the mesh may be coated with materials like galvanization to enhance corrosion resistance.

5. Packaging and Distribution The finished mesh is rolled or flat-packed for shipping to construction sites or manufacturers.

Benefits for Industrial Manufacturers

Incorporating reinforcing mesh into industrial construction projects provides numerous benefits

1. Enhanced Structural Integrity Reinforcing mesh significantly increases the tensile strength of concrete, helping resist cracking and overstress.

2. Cost-Effectiveness By reducing material usage and labor costs, reinforcing mesh offers a cost-effective solution for construction projects. Its quick installation can lead to reduced labor expenses.

3. Versatility Reinforcing mesh can be adapted to a wide range of applications, from commercial buildings to industrial factories. It can be cut and shaped to meet specific project needs.

4. Durability Products made with reinforcing mesh are more durable, leading to extended service life and lower maintenance costs for manufacturers.

5. Safety By improving the overall strength of structures, reinforcing mesh contributes to building safety, thereby reducing the likelihood of structural failures.

Conclusion

As the demand for robust construction materials grows, the use of reinforcing mesh in industrial manufacturing becomes increasingly essential. Its ability to enhance concrete strength, reduce project costs, and ensure long-term durability makes it a preferred choice among manufacturers. By understanding the composition, manufacturing process, and benefits of reinforcing mesh, industrial manufacturers can leverage this vital resource to produce safer, more resilient structures that stand the test of time. Investing in high-quality reinforcing mesh not only meets current construction challenges but also paves the way for future innovations in the industry.

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025