Dec . 11, 2024 09:18 Back to list

Reinforcing Mesh A395 Manufacturing Processes and Industry Insights

Reinforcing Mesh A395 Importance and Factory Insights

Reinforcing mesh, specifically the A395 type, plays a crucial role in the construction and building industries, providing essential support for concrete structures. This article discusses the significance of A395 reinforcing mesh and offers insights into the factories involved in its production, ensuring that construction projects are both safe and durable.

What is A395 Reinforcing Mesh?

A395 reinforcing mesh is a grid-like structure made from high-quality steel wires. These wires are welded together to form a sheet that provides tensile strength, ensuring that concrete, which is naturally strong in compression, can withstand various forces when integrated with this mesh. This combination is especially essential in projects involving roadways, bridges, and large buildings, where concrete must bear heavy loads and resist cracking over time.

The Manufacturing Process

The manufacturing of A395 reinforcing mesh involves several steps to ensure the highest standards of quality and performance. It begins with the selection of steel wire, which must meet specific standards for strength and ductility. Factories typically source their materials from reputable suppliers, maintaining a consistent supply of high-grade steel.

1. Wire Drawing The initial step involves drawing wires through a series of progressively smaller dies to achieve the desired diameter, which is typically around 5-12 mm for A395 mesh.

2. Cutting and Bending Once the steel wire is prepared, it is cut into uniform lengths that will form the mesh grid. Some wires may be pre-bent, depending on the design specifications required for different construction applications.

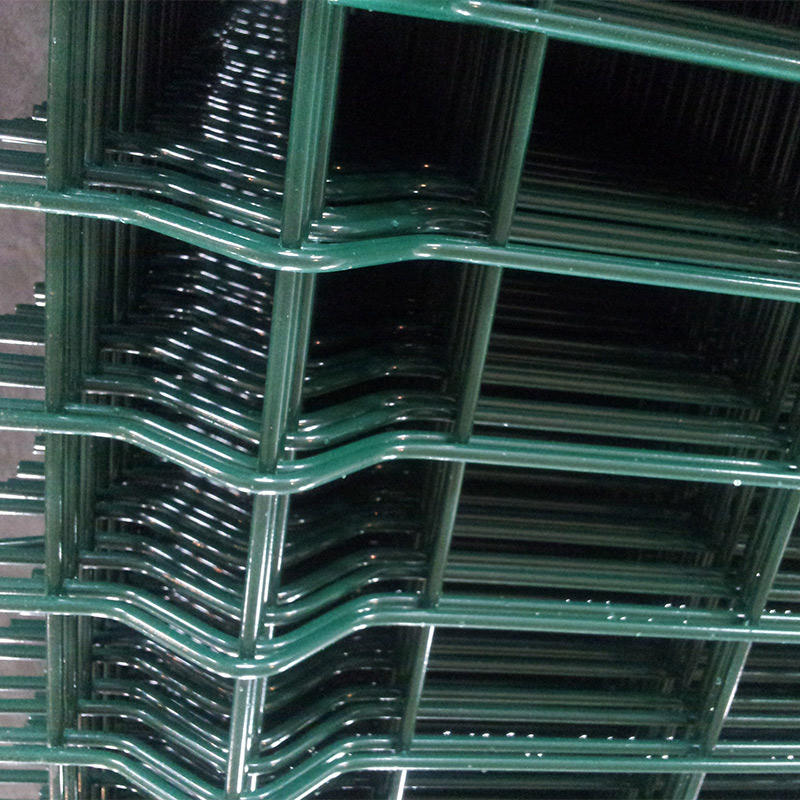

3. Welding The cut wires are then arranged into a grid format and welded together at their intersections, creating a robust mesh. Advanced machinery is employed to ensure precision and uniformity, leading to a high-quality finished product that adheres to industry standards.

reinforcing mesh a395 factories

4. Surface Treatment To enhance durability and resistance to corrosion, the A395 mesh may undergo surface treatments such as galvanization or coating with protective materials. This step is crucial, as it ensures the longevity of the mesh, especially in environments exposed to moisture or harsh chemicals.

5. Quality Control Lastly, rigorous quality control measures are implemented throughout the production process. Factories conduct tests for tensile strength, weld integrity, and dimensional accuracy to guarantee that the A395 reinforcing mesh meets established standards and customer specifications.

The Role of Factories in A395 Production

Factories that produce A395 reinforcing mesh play a critical role in ensuring that the construction industry has access to reliable materials. The efficiency and modern technology employed in these factories not only improve production speed but also enhance the overall quality of the mesh.

Sustainable Practices

In recent years, many factories have begun adopting sustainable practices in their production processes. This includes using recycled materials in the production of steel wire, minimizing waste, and implementing energy-efficient manufacturing methods. These practices not only contribute to environmental sustainability but also reduce costs, making quality reinforcing mesh more accessible for construction projects.

Conclusion

The A395 reinforcing mesh is an indispensable component of modern construction, providing essential structural support that enhances the safety and durability of concrete buildings and infrastructures. Factories that manufacture this mesh utilize advanced technology and rigorous quality control processes to ensure that the final product meets the demands of the construction industry. As construction continues to evolve, the role of reinforcing mesh will remain vital, with manufacturers continually striving for innovation and sustainability in their production practices. As such, investing in high-quality A395 reinforcing mesh and supporting responsible manufacturing practices is crucial for the future of construction and infrastructure development.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025