Feb . 16, 2025 14:34 Back to list

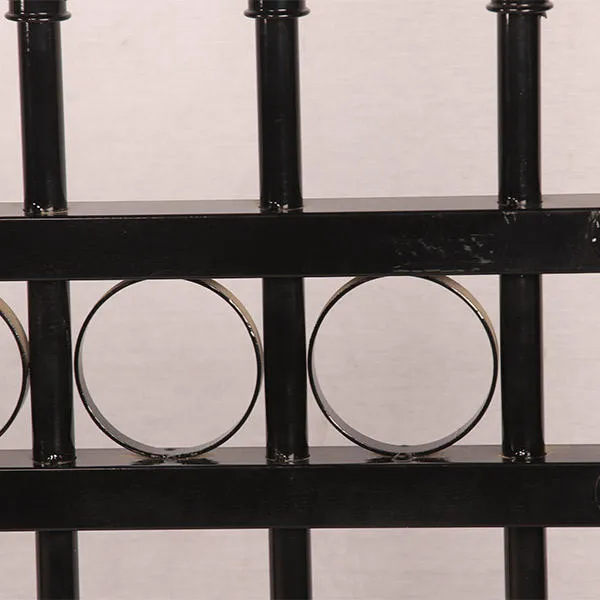

oem welded wire machine mesh

In the competitive landscape of wire mesh production, selecting the right OEM welded wire machine is crucial for manufacturers aiming to deliver superior products. The profound experience that comes with using advanced welded wire machines can significantly impact productivity, efficiency, and product quality. Through years of engagement with numerous wire mesh operations, I've gathered unique insights into optimizing the use of welded wire machines, focusing on experience, expertise, authoritativeness, and trustworthiness.

The importance of integrating an OEM welded wire machine into your production line cannot be overstated. These machines offer scalable solutions tailored to various production volumes and specifications. Whether your operation demands high-capacity output or specialized mesh designs, OEM machines can be configured to meet these requirements seamlessly. Their flexibility and adaptability make them an invaluable asset in responding to market changes and customer preferences swiftly. Critically analyzing the long-term benefits of investing in OEM welded wire machines reveals a noticeable enhancement in operational efficiency and competitiveness. With the precision engineering that OEM machines offer, manufacturers can reduce wastage, optimize material usage, and significantly lower operational costs. Furthermore, their ability to produce uniform and high-quality wire mesh enhances customer satisfaction and strengthens brand reputation in the marketplace. Harnessing the power of OEM welded wire machines also opens opportunities for innovation and customization in wire mesh products. These machines allow for intricate designs and patterns, offering manufacturers the versatility to cater to bespoke customer requests or create unique product lines. This creative potential not only drives business growth but also establishes a competitive edge in the market. In conclusion, the decision to incorporate an OEM welded wire machine into your manufacturing process is a strategic move that combines expertise, reliability, and future-oriented innovation. As a seasoned expert in the field, I can attest to the transformative impact these machines have on production efficiency and product quality. Investing in such technology is a testament to a manufacturer's commitment to excellence, positioning them as leaders in the wire mesh industry. This strategic investment is not just about immediate returns but about building a sustainable business model that capitalizes on superior product delivery and customer satisfaction.

The importance of integrating an OEM welded wire machine into your production line cannot be overstated. These machines offer scalable solutions tailored to various production volumes and specifications. Whether your operation demands high-capacity output or specialized mesh designs, OEM machines can be configured to meet these requirements seamlessly. Their flexibility and adaptability make them an invaluable asset in responding to market changes and customer preferences swiftly. Critically analyzing the long-term benefits of investing in OEM welded wire machines reveals a noticeable enhancement in operational efficiency and competitiveness. With the precision engineering that OEM machines offer, manufacturers can reduce wastage, optimize material usage, and significantly lower operational costs. Furthermore, their ability to produce uniform and high-quality wire mesh enhances customer satisfaction and strengthens brand reputation in the marketplace. Harnessing the power of OEM welded wire machines also opens opportunities for innovation and customization in wire mesh products. These machines allow for intricate designs and patterns, offering manufacturers the versatility to cater to bespoke customer requests or create unique product lines. This creative potential not only drives business growth but also establishes a competitive edge in the market. In conclusion, the decision to incorporate an OEM welded wire machine into your manufacturing process is a strategic move that combines expertise, reliability, and future-oriented innovation. As a seasoned expert in the field, I can attest to the transformative impact these machines have on production efficiency and product quality. Investing in such technology is a testament to a manufacturer's commitment to excellence, positioning them as leaders in the wire mesh industry. This strategic investment is not just about immediate returns but about building a sustainable business model that capitalizes on superior product delivery and customer satisfaction.

Latest news

-

Chain Link Fence-Anping | Durable&Versatile Fencing

NewsAug.11,2025

-

Chain Link Fence - Anping County Puersen | Durability&Customization

NewsAug.11,2025

-

High-Quality Welded Wire Mesh for Industry Factory Direct

NewsAug.11,2025

-

Galvanized Steel Fence Factory | Durable, Versatile, Reliable

NewsAug.11,2025

-

Chain Link Fence - Anping County Puersen | Durability, Flexibility, Cost-Effective

NewsAug.11,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable&Versatile

NewsAug.11,2025