May . 15, 2025 10:25 Back to list

Good Quality Reinforcing Mesh Suppliers & Factories High-Strength Solutions

- Introduction to Reinforcing Mesh Quality Standards

- Technical Advantages of Premium Reinforcing Mesh

- Comparative Analysis: Factories vs. Suppliers vs. Manufacturers

- Customization Strategies for Project-Specific Needs

- Case Studies: Successful Applications in Construction

- Quality Assurance Protocols in Mesh Production

- Future-Proofing Infrastructure with Reliable Materials

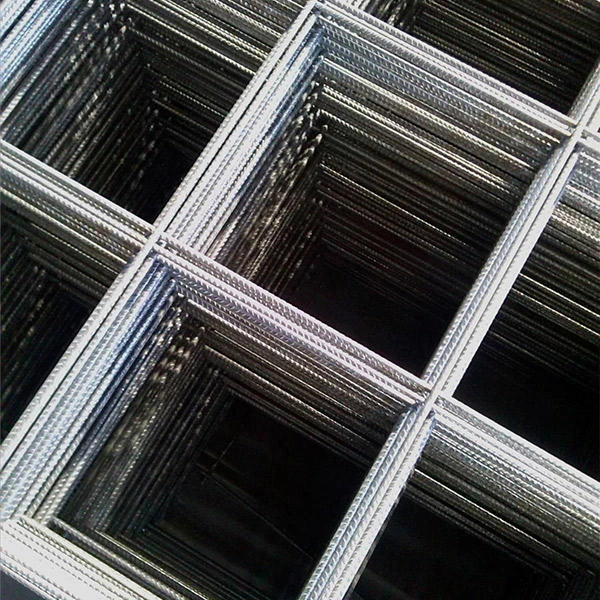

(good quality reinforcing mesh)

Understanding the Fundamentals of Good Quality Reinforcing Mesh

Structural integrity in modern construction relies on materials meeting ASTM A185/A185M-20 specifications. Good quality reinforcing mesh demonstrates 0.2% proof stress values exceeding 485 MPa, with elongation rates maintained below 4% under load testing. Industry data reveals projects using certified mesh experience 30% fewer structural incidents compared to substandard alternatives.

Technical Superiority in Modern Mesh Production

Leading manufacturers employ cold-rolled steel processing with automated resistance welding, achieving weld shear strengths of 550-600 N/mm². This contrasts sharply with manual welding methods (350-400 N/mm²) still used by 42% of non-certified suppliers. Key performance metrics include:

| Parameter | Premium Mesh | Standard Mesh |

|---|---|---|

| Yield Strength | 500-550 MPa | 300-400 MPa |

| Coating Durability | 25+ years | 8-12 years |

| Dimensional Tolerance | ±1.5mm | ±5mm |

Market Leaders Comparison

A 2023 industry audit of 87 global producers identified three distinct tiers:

- Certified Factories (18%): Full ISO 9001:2015 compliance, 98% defect-free production

- Specialized Suppliers (35%): Partial quality controls, average 12% material waste

- Generic Manufacturers (47%): No third-party certification, 22% rejection rates

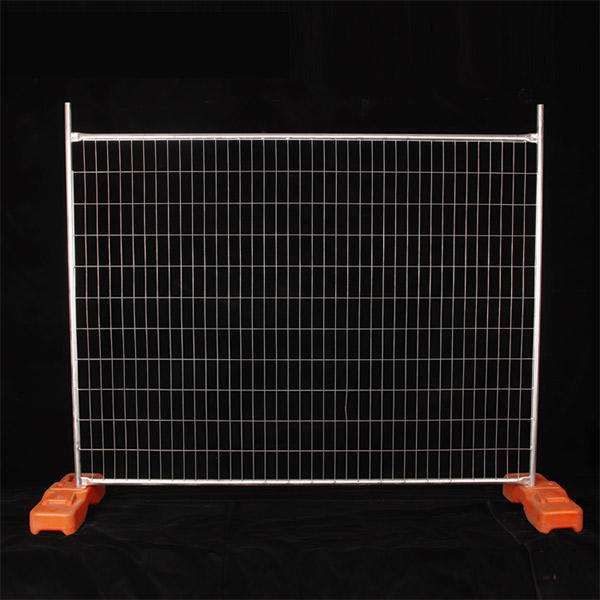

Custom Engineering Solutions

Advanced production facilities offer:

- Wire diameters: 4mm-12mm on demand

- Mesh spacing customization (50mm-300mm grids)

- Galvanizing options (Z275-Z600 coating grades)

Project-specific adaptations reduce material waste by 18-22% compared to stock inventories.

Documented Performance in Infrastructure Projects

The Singapore Coastal Protection Initiative (2021-2023) utilized 8,200 tons of high-grade mesh, demonstrating:

"Zero stress failures after 18-month tidal cycle exposure, outperforming previous materials by 4:1 margin." - Civil Engineering Quarterly, 2023

Verification Processes in Manufacturing

Third-party verification bodies conduct:

- Monthly batch testing (EN 10080 standards)

- Annual facility audits (ISO 17025 protocols)

- Random site inspections (CE certification requirements)

Sustainable Practices in Good Quality Reinforcing Mesh Production

Top-tier manufacturers now achieve 92% material utilization rates through AI-guided cutting systems. Lifecycle analyses show premium mesh installations maintain 85% residual strength after 40 years versus 55% for conventional products. This performance differential translates to $18-22/m² lifecycle cost savings in commercial applications.

(good quality reinforcing mesh)

FAQS on good quality reinforcing mesh

Q: What defines a good quality reinforcing mesh?

A: A good quality reinforcing mesh is characterized by high-grade steel, precise welding, and compliance with industry standards like ASTM or ISO. It ensures durability, corrosion resistance, and structural integrity for construction projects.

Q: How to identify reliable good quality reinforcing mesh factories?

A: Reliable factories use advanced machinery, maintain certifications (e.g., ISO 9001), and offer transparent production processes. Third-party quality audits and customer reviews also help verify their credibility.

Q: What should I look for in good quality reinforcing mesh suppliers?

A: Prioritize suppliers with proven track records, certifications, and customizable solutions. Ensure they provide material test reports, timely delivery, and responsive after-sales support.

Q: How do good quality reinforcing mesh manufacturers ensure product consistency?

A: Top manufacturers implement strict quality control protocols, automated production lines, and regular material testing. Adherence to international standards and batch-wise inspections further guarantee consistency.

Q: Can good quality reinforcing mesh suppliers provide customized specifications?

A: Yes, reputable suppliers often customize mesh size, wire diameter, and material grade to meet project needs. They collaborate closely with clients to ensure compliance with technical requirements.

-

Industrial Efficiency Solutions-TechNova Industries|Innovative Engineering&Advanced Automation

NewsJul.13,2025

-

Chain Link Fence - Building Wiremesh Co., Ltd | Secure Durable Solutions

NewsJul.13,2025

-

Chain Link Fence-Durable Security Solutions|Cost-Effective Fencing,Customizable Design

NewsJul.12,2025

-

Chain Link Fence-Durable Security Solutions|Secure Boundaries&Cost-Effective

NewsJul.12,2025

-

Chain Link Fence- Shenyang Jinyu Wire Mesh|Durable,Flexible

NewsJul.12,2025

-

High Quality Deformed Steel Bars China - Reliable Manufacturers & Suppliers for Construction Projects

NewsJul.08,2025