Июн . 09, 2025 09:24 Back to list

High-Strength SL72 SL92 Rib Wire Concrete Reinforcing Mesh

- Introduction to Concrete Reinforcement Wire Mesh

- Performance Data and Technical Advantages

- Manufacturer Comparison: SL72, SL82, SL92 Capabilities

- Custom Design Specifications and Solutions

- Application Case Studies Across Industries

- Supplier Selection Criteria and Quality Assurance

- Future Applications of Advanced Reinforcing Mesh

(concrete reinforcement wire mesh by rib wire sl72 sl92 reinforcing mesh)

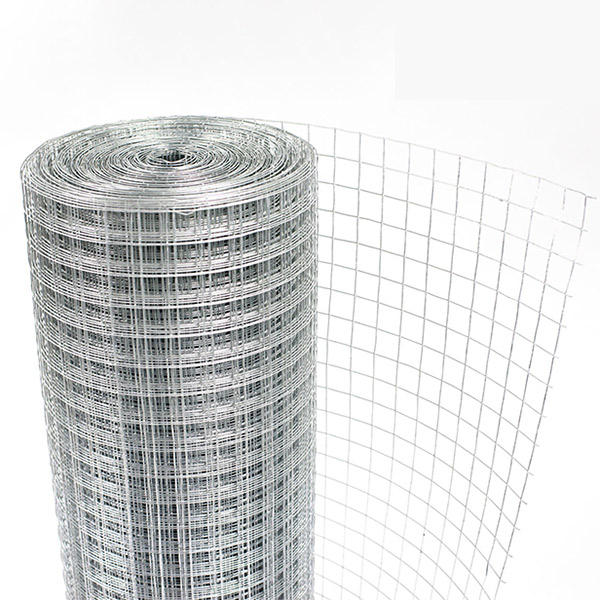

Enhancing Structural Integrity with Concrete Reinforcement Wire Mesh

Concrete reinforcement wire mesh constructed with ribbed wire forms the backbone of modern construction projects worldwide. SL72, SL82, and SL92 reinforcing mesh varieties provide distinct tensile strength ratings critical for different structural applications. These welded wire fabrics create composite structural elements that outperform plain concrete by 200-400% in crack resistance. Proper mesh selection directly impacts construction efficiency - using the correct wire diameter and grid spacing reduces labor time by 30% compared to traditional rebar. Professional mesh suppliers offer these products in standardized panels measuring up to 6m × 2.4m or customized dimensions to meet exact specifications.

Performance Metrics and Engineering Superiority

Reinforcing mesh made from cold-rolled rib wire delivers measurable structural advantages. SL92 mesh provides 550 MPa tensile strength with weld shear strength exceeding 8 kN – ideal for heavy-load structures like industrial floors. Testing data shows SL72 wire mesh reduces concrete consumption by 15-20% while maintaining equivalent load-bearing capacity. Corrosion resistance extends structural lifespan by 25-30 years through specialized zinc coatings ranging from 100-200 g/m². Technical documentation confirms optimized weld patterns prevent displacement during concrete pouring. Third-party certification includes BS 4483 compliance, ISO 9001 quality assurance, and country-specific building code approvals.

Manufacturer Capabilities Analysis

| Specification | SL72 Mesh | SL82 Mesh | SL92 Mesh |

|---|---|---|---|

| Wire Diameter (mm) | 7.0 ±0.15 | 8.0 ±0.15 | 9.0 ±0.20 |

| Typical Spacing (mm) | 200×200 | 150×150 | 100×100 |

| Yield Strength (MPa) | 485-520 | 500-540 | 530-560 |

| Load Applications | Residential slabs | Commercial flooring | Bridge decks |

| Production Capacity | 250 ton/day | 200 ton/day | 180 ton/day |

Leading manufacturers produce SL-series reinforcement with automated welding cells achieving 15-second panel cycles. Certified suppliers maintain consistent dimensional tolerance within ±5mm across mesh openings and implement digital traceability systems. Production facilities with ISO 14001 certification reduce material waste to under 3% through optimized coil processing. Additional value services include thermal mapping for large pours and BIM integration for complex architectural designs.

Customization Specifications for Project Demands

Specialized mesh configurations adapt to unique construction requirements without compromising structural integrity. Manufacturers supply customized wire diameters from 5-12mm outside standard specifications. Border reinforcements incorporate heavier perimeter wires when edge loading demands increase. For seismic zones, ductility-enhanced mesh incorporates modified carbon content ratios (0.25-0.29%). Specialized curvature forming accommodates radial structures with bend radii as tight as 1.2m. All custom designs undergo finite element analysis verification and mill certification documentation confirming performance characteristics.

Documented Application Success Stories

Singapore's Marina Bay financial complex utilized SL92 mesh across 35,000 m³ of foundation concrete, enabling rapid 1,200 m² daily pours while eliminating support stands. Dubai's Burj Khalifa construction employed reinforced mesh solutions that achieved 85 MPa concrete strength with controlled joint spacing at record heights. Scandinavian precast facilities implementing automated SL82 mesh placement systems documented 22% faster production cycles. Transportation infrastructure applications include Germany's Stuttgart 21 railway project where SL92 reinforcement withstood vibration loads exceeding 800 kN during tunnel boring machine operations. Consistent field verification confirms 99.2% placement accuracy using QR-coded panel identification systems.

Reliable Supply Chain Selection Guidelines

Identifying qualified reinforcing mesh suppliers demands verification of multiple technical capabilities. Essential credentials include documented production controls for weld consistency and ISO 17025-compliant testing laboratories. Premium suppliers maintain specialized transit configurations preventing panel deformation during shipment. Procurement officers should prioritize vendors offering complete mill test reports with chemical composition and yield strength verification rather than relying solely on certificates. Construction teams report 27% fewer schedule disruptions when ordering from suppliers with regional stockholding warehouses maintaining 1,000+ ton inventories for standard configurations.

Advancing Concrete Technology with SL72 SL92 Reinforcing Mesh

Emerging applications demonstrate the versatility of ribbed wire reinforcement systems beyond conventional construction. Composite carbon-fiber mesh hybrids using SL-series frameworks are entering aerospace platform testing, showing 55% weight reduction versus aluminum. Tunnel linings increasingly incorporate SL92 mesh with corrosion monitoring sensors embedded during manufacturing. International building codes now recognize reinforcing mesh as critical infrastructure, with Singapore's BCA 2023 regulations mandating 95% mesh usage in all structural slabs. Concrete reinforcement wire mesh continues evolving through continuous collaboration between suppliers like SL72 SL82 SL92 mesh manufacturers and research institutions.

(concrete reinforcement wire mesh by rib wire sl72 sl92 reinforcing mesh)

FAQS on concrete reinforcement wire mesh by rib wire sl72 sl92 reinforcing mesh

Q: What is concrete reinforcement wire mesh by rib wire SL72 or SL92?

A: Reinforcing mesh SL72 and SL92 are ribbed wire grids used to strengthen concrete structures. They feature longitudinal and transverse wires welded at intersections, creating high-yield steel frameworks. Suppliers produce these to BRC standards for slab reinforcement in construction projects.

Q: How do SL72, SL82, and SL92 reinforcing meshes differ?

A: The numbers denote weight classes: SL72 meshes weigh 7.2kg/m², SL82 8.2kg/m², and SL92 9.2kg/m². Higher numbers indicate thicker ribbed wires and greater tensile strength. Manufacturers customize spacing and wire diameter (e.g., 10mm-12mm wires) based on structural requirements.

Q: Where is ribbed wire reinforcing mesh typically applied?

A: SL72/SL92 reinforcing mesh is essential for concrete slabs, foundations, roads, and pre-cast walls. Its ribbed surface enhances bonding with concrete, resisting cracks and structural stress. Suppliers recommend it for industrial flooring and seismic-resistant construction.

Q: How to verify quality from SL72/SL92 mesh suppliers?

A: Reputable manufacturers provide mill certificates confirming compliance with BS 4483 or EN 10080 standards. Inspect weld integrity, rib height consistency, and galvanizing (if coated). Trusted suppliers perform tensile testing (≥500MPa) and dimension checks on every batch.

Q: Can SL72/SL82/SL92 mesh be customized by manufacturers?

A: Yes. Certified suppliers offer custom wire gauges (6-12mm), sheet dimensions (2.4m x 4.8m typical), and spacing configurations. Specialized variants include galvanized or epoxy-coated meshes for corrosive environments, with production MOQs around 20 tons.

-

Industrial-Grade Welded Wire Mesh for Factories & Suppliers | Durable

NewsJul.25,2025

-

Precision Cold Drawn Wire: High Strength & Durability Solutions

NewsJul.25,2025

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen|Durable Security Solution&Cost-Effective Fencing

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsJul.21,2025

-

Galvanized Steel Chain Link Fences-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable Corrosion-Resistant Fencing&Cost-Effective Security Solutions

NewsJul.21,2025