Ноя . 06, 2024 15:30 Back to list

4 points double strand barbed wire manufacturers and suppliers in the industry

The Evolution and Importance of 4% Points Double Strand Barbed Wire Factories

Barbed wire represents one of the most significant innovations in modern fencing technology. Among its various forms, the 4% points double strand barbed wire stands out for its robustness and effectiveness in securing perimeters. The factories producing this specialized fencing material have evolved with advancements in manufacturing and design, meeting the ever-increasing demand for security in both agricultural and industrial applications.

Understanding 4% Points Double Strand Barbed Wire

At its core, barbed wire consists of two twisted strands of wire with sharp points attached at regular intervals. The designation 4% points refers to the specific design characteristic where 4% of the wire's length is utilized for the barbs. This design balances the wire's strength with its ability to deter intruders effectively.

The double strand configuration enhances durability and resistance to breakage while simultaneously increasing the wire's deterrent properties. It is a preferred choice for farmers, ranchers, and businesses seeking to safeguard property lines while minimizing the risk of livestock escape or unauthorized access.

Manufacturing Process

The manufacturing of 4% points double strand barbed wire involves several key steps wire drawing, twisting, and barb attachment. Initially, raw steel is drawn into thinner strands using a process that strengthens the metal. This elongation is crucial because it directly correlates to the wire's tensile strength, making it more resistant to deformation when subjected to tension.

Next, the wires are twisted together. This twisting not only allows for the formation of a double-strand but also contributes to the wire's overall stability. Once the strands are twisted, the barb points are attached. These are typically formed from thinner wire, which is shaped into sharp points and affixed to the main strands at predetermined intervals. This meticulous process ensures uniform distances between barbs, enhancing both functionality and aesthetics.

Finally, the barbed wire goes through a coating process to protect against rust and weathering. Many manufacturers apply zinc galvanization, which provides an additional layer of durability and increases the wire’s lifespan significantly. This coating is critical, especially for installations in areas with harsh weather conditions.

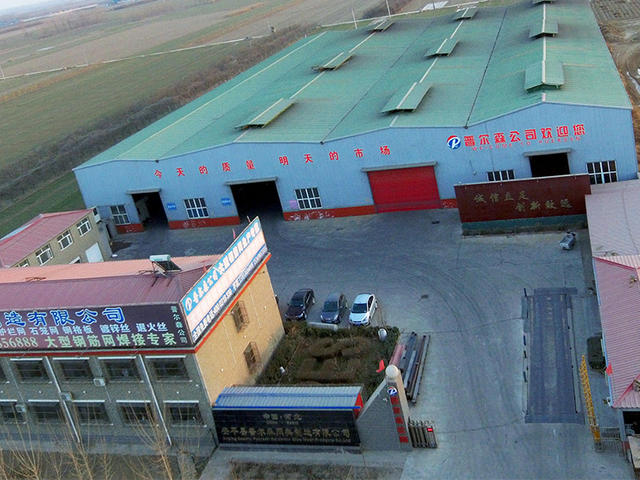

4 points double strand barbed wire factories

The Role of Technology in Barbed Wire Production

Over the past few decades, technological advancements have revolutionized the way barbed wire factories operate. Automation in production lines has significantly increased the efficiency and consistency of manufacturing processes. State-of-the-art machinery now allows for quicker wire drawing, precise barb fabrication, and better quality control.

Moreover, computer-aided design (CAD) technologies enable manufacturers to experiment with different barb shapes and wire tensions, leading to customized solutions for specific applications. These improvements have not only reduced production costs but have also enhanced the quality of the final product.

The Market Demand

The demand for 4% points double strand barbed wire continues to grow, driven by various factors. In agriculture, it serves as a crucial tool for livestock management and crop protection. Farmers utilize this fencing solution to contain animals, preventing them from straying into roads or neighboring properties. Additionally, it helps deter wildlife from entering cultivated fields.

In the industrial sector, 4% points double strand barbed wire is vital for enhancing security in commercial operations. Businesses use it to protect facilities, secure inventory, and ensure the safety of employees. With rising concerns about trespassing and theft, the need for effective security measures has never been more critical, propelling barbed wire as a go-to choice for many organizations.

Conclusion

The factories producing 4% points double strand barbed wire have adapted to meet the changing needs of consumers while ensuring the production of a reliable and effective product. Through advancements in manufacturing technology and a keen understanding of market demand, these factories play a pivotal role in enhancing security and privacy across various landscapes. As we look to the future, the evolution of barbed wire will likely continue, reflecting advancements in materials science and security technologies, ensuring that it remains a staple in fencing solutions worldwide.

-

Chain Link Fence-Anping County Puersen|Galvanized Steel, Durability, Custom Solutions

NewsAug.05,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable&Versatile

NewsAug.05,2025

-

Welded Wire Mesh for Industrial Factories: Durable & Strong

NewsAug.05,2025

-

Heavy-Duty Welded Wire Mesh for Industrial Factories

NewsAug.04,2025

-

Chain Link Fence - Anping County Puersen | Durable, Versatile, Reliable

NewsAug.03,2025

-

Chain Link Fence: Durable, Versatile, and Reliable Fencing Solution|Galvanized Steel Fence Manufacturers

NewsAug.03,2025