Set . 28, 2024 16:39 Back to list

Exploring the World of Black Nail Wire Manufacturing and Its Key Players

The Rise of Black Nail Wire Factories A Modern Industrial Perspective

In today’s fast-paced industrial landscape, the significance of efficient manufacturing processes and the production of high-quality materials cannot be overstated. Among various manufacturing sectors, black nail wire factories have emerged as a vital component in supplying the construction, automotive, and manufacturing industries. This article delves into the key aspects of black nail wire production, exploring its applications, manufacturing processes, and the challenges faced by these factories.

Understanding Black Nail Wire

Black nail wire is a type of wire that has been coated in black oxide, giving it both aesthetic appeal and increased corrosion resistance. This wire is primarily used to manufacture nails, staples, and other fasteners. The black finish not only enhances the wire’s durability but also provides a more visually appealing product for consumers and builders alike. With the growing demand for reliable and durable fasteners, black nail wire has established a critical niche in various industrial sectors.

Manufacturing Process

The production of black nail wire involves several key steps that ensure the wire meets strict quality standards. Initially, steel rods are drawn through a series of dies to achieve the desired diameter. This cold drawing process enhances the tensile strength of the wire, making it suitable for heavy-duty applications.

After the wire is drawn, it undergoes a process called annealing, which involves heating the wire to a specific temperature and then slowly cooling it. This step is crucial as it relieves any internal stresses within the wire, thereby improving its workability and preventing brittleness.

Following annealing, the wire is coated with a black oxide finish. This is typically achieved through a chemical process where the wire is submerged in a solution that facilitates the oxidation of the surface. The resulting black finish not only provides an attractive appearance but also enhances the wire’s resistance to rust and corrosion, making it ideal for applications in outdoor settings.

Applications of Black Nail Wire

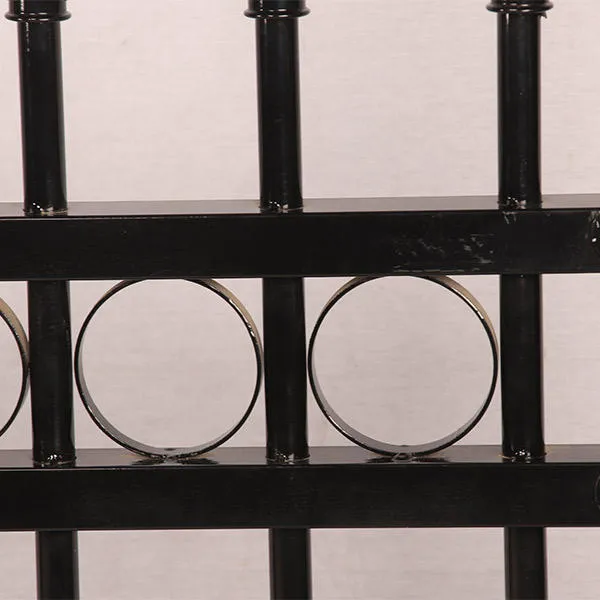

black nail wire factories

Black nail wire is predominantly used in the construction industry, where it is transformed into nails for framing, roofing, and decking purposes. The black finish is particularly favored in projects where aesthetic considerations are paramount, as it blends seamlessly with dark materials and surfaces.

Moreover, the automotive industry utilizes black nail wire in the assembly of various components, including interior fittings and structural parts. The enhanced corrosion resistance of black-finished wire ensures the longevity of these components, which is crucial in maintaining vehicle integrity.

In addition to construction and automotive applications, black nail wire also finds uses in furniture manufacturing, packaging, and even in agriculture for securing plants and structures. The versatility of black nail wire makes it an invaluable resource across multiple sectors.

Challenges Faced by Black Nail Wire Factories

Despite the promising market for black nail wire, factories in this sector encounter several challenges. One significant concern is the volatility of raw material prices, particularly steel. Fluctuations in steel prices can significantly impact production costs, leading to pricing challenges in a competitive market.

Moreover, the environmental regulations surrounding manufacturing processes have become increasingly stringent. Black nail wire factories must invest in sustainable practices and technologies to minimize their environmental footprint, which can lead to increased operational costs.

Additionally, maintaining high-quality standards while scaling production poses a challenge. As demand grows, factories must leverage advanced technology and skilled labor to ensure that the quality of products is not compromised.

Conclusion

Black nail wire factories play a crucial role in several key industries, offering durable and aesthetically pleasing products that meet the needs of modern construction and manufacturing. As these factories navigate the challenges of raw material prices, environmental regulations, and the demand for quality, their ability to innovate and adapt will determine their success in the evolving industrial landscape. Ultimately, the future of black nail wire production appears promising, with ongoing advancements set to enhance both efficiency and product quality in this essential sector.

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025