Jan . 14, 2025 09:41 Back to list

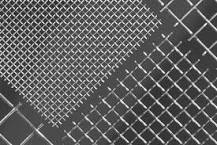

welded wire fabric concrete

Welded wire fabric concrete, known for its robustness and versatility, has become an indispensable material in modern construction. This product combines steel wires welded at their intersections to form a grid or mesh, ultimately embedded in concrete surfaces. This blend of materials is pivotal in enhancing the structural performance of projects, from large-scale infrastructure to residential buildings.

Trust and reliability in welded wire fabric concrete are built through its widespread application and success in diverse projects worldwide. Whether in roadways, bridges, or high-rise buildings, the use of welded wire fabric has been proven to increase the lifespan and integrity of structures. It is trusted by major construction firms and is a recommended practice in structural engineering guides. Innovations in this product’s manufacturing process have also led to advancements in corrosion resistance, giving architects more flexibility in choosing welded wire fabric for challenging environments such as coastal regions. The application of protective coatings ensures that the steel within the concrete is shielded from moisture and corrosive elements, thereby extending the structure's life expectancy. In summary, the adoption of welded wire fabric concrete in construction projects is driven by its exceptional performance and reliability. Its engineering properties reduce costs and improve safety and longevity, aligning with E-E-A-T principles by demonstrating both expert application and trustworthiness in diverse construction scenarios. Through continuous innovation and proven success, it remains a preferred choice for engineers aiming to meet contemporary building demands. This underscores its unmatched value, making it a solid investment for future-proofing infrastructure and residential projects alike.

Trust and reliability in welded wire fabric concrete are built through its widespread application and success in diverse projects worldwide. Whether in roadways, bridges, or high-rise buildings, the use of welded wire fabric has been proven to increase the lifespan and integrity of structures. It is trusted by major construction firms and is a recommended practice in structural engineering guides. Innovations in this product’s manufacturing process have also led to advancements in corrosion resistance, giving architects more flexibility in choosing welded wire fabric for challenging environments such as coastal regions. The application of protective coatings ensures that the steel within the concrete is shielded from moisture and corrosive elements, thereby extending the structure's life expectancy. In summary, the adoption of welded wire fabric concrete in construction projects is driven by its exceptional performance and reliability. Its engineering properties reduce costs and improve safety and longevity, aligning with E-E-A-T principles by demonstrating both expert application and trustworthiness in diverse construction scenarios. Through continuous innovation and proven success, it remains a preferred choice for engineers aiming to meet contemporary building demands. This underscores its unmatched value, making it a solid investment for future-proofing infrastructure and residential projects alike.

Next:

Latest news

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025