Feb . 18, 2025 04:58 Back to list

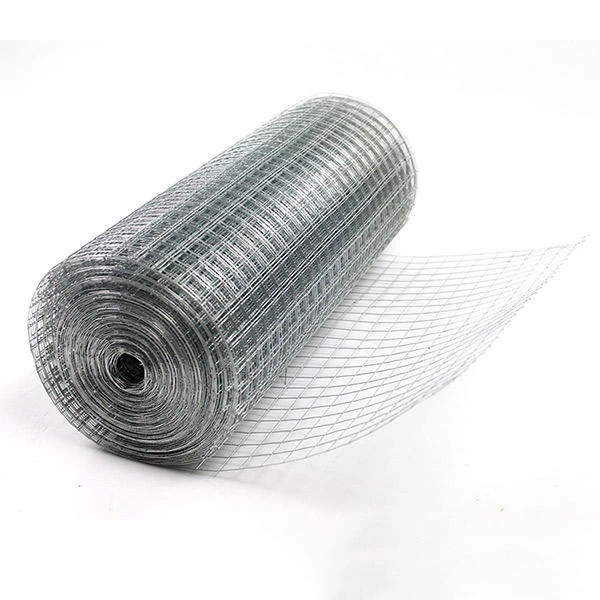

oem concrete reinforcing welded wire mesh

In the dynamic world of construction and infrastructure development, the choice of materials can significantly impact both the integrity and longevity of a project. Among these materials, OEM concrete reinforcing welded wire mesh stands out as a vital component renowned for its strength, versatility, and efficiency. Understanding its application and benefits is crucial for anyone involved in construction, from engineers to site managers.

OEM producers of welded wire mesh often provide detailed technical support, drawing from years of experience in the field. This support can prove invaluable to architects and engineers during the design phase, allowing them to optimize mesh configurations for unique structural applications. Such collaboration ensures that the reinforced concrete performs to its maximum potential, reducing the risk of costly structural failures. The trustworthiness of OEM-sourced welded wire mesh also lies in its traceable production process. Each batch is meticulously documented and tested to ensure consistency and performance. This level of traceability and quality control reassures contractors and building inspectors alike that the materials used are of the highest calibre. For those new to the concept or utilization of welded wire mesh, training and educational resources are readily available. Many OEMs offer seminars and workshops to showcase best practices in the field, promoting an informed use of their products. These initiatives are designed not only to sell a product but to elevate the standards of construction through knowledge and innovation. The rise of sustainable building practices further elevates the value of using welded wire mesh. Its efficient use of raw materials aligns well with green building certifications and environmental assessments. In an era where the carbon footprint of construction projects is scrutinized, selecting materials that contribute to eco-friendly building solutions is not only responsible but increasingly necessary. In summary, the inclusion of OEM concrete reinforcing welded wire mesh in construction projects offers numerous benefits that span structural integrity, compliance, and sustainability. Its expert design and manufacturing processes ensure a reliable product that can withstand the tests of time and nature. The authoritative assurance from industry-leading OEMs and the trust established through quality and performance create a compelling case for its widespread adoption in modern engineering and construction. As the construction industry continues to evolve, the integration of such innovative materials will undoubtedly play a critical role in shaping the sustainable infrastructures of tomorrow.

OEM producers of welded wire mesh often provide detailed technical support, drawing from years of experience in the field. This support can prove invaluable to architects and engineers during the design phase, allowing them to optimize mesh configurations for unique structural applications. Such collaboration ensures that the reinforced concrete performs to its maximum potential, reducing the risk of costly structural failures. The trustworthiness of OEM-sourced welded wire mesh also lies in its traceable production process. Each batch is meticulously documented and tested to ensure consistency and performance. This level of traceability and quality control reassures contractors and building inspectors alike that the materials used are of the highest calibre. For those new to the concept or utilization of welded wire mesh, training and educational resources are readily available. Many OEMs offer seminars and workshops to showcase best practices in the field, promoting an informed use of their products. These initiatives are designed not only to sell a product but to elevate the standards of construction through knowledge and innovation. The rise of sustainable building practices further elevates the value of using welded wire mesh. Its efficient use of raw materials aligns well with green building certifications and environmental assessments. In an era where the carbon footprint of construction projects is scrutinized, selecting materials that contribute to eco-friendly building solutions is not only responsible but increasingly necessary. In summary, the inclusion of OEM concrete reinforcing welded wire mesh in construction projects offers numerous benefits that span structural integrity, compliance, and sustainability. Its expert design and manufacturing processes ensure a reliable product that can withstand the tests of time and nature. The authoritative assurance from industry-leading OEMs and the trust established through quality and performance create a compelling case for its widespread adoption in modern engineering and construction. As the construction industry continues to evolve, the integration of such innovative materials will undoubtedly play a critical role in shaping the sustainable infrastructures of tomorrow.

Latest news

-

Black Annealed Wire Specification - High Quality & Custom Options from Leading Factories, Suppliers, Manufacturers

NewsJun.10,2025

-

High-Quality 18 Gauge Black Steel Wire Reliable Factories & Suppliers

NewsJun.10,2025

-

Chain Link Fence Gates - Durable & Secure Access Solutions

NewsJun.10,2025

-

Premium Cold Rolled Steel Bar Supplier High Strength & Precision

NewsJun.10,2025

-

Galvanized Wire Brick Force Mesh - Corrosion Resistant

NewsJun.09,2025

-

Galvanized Metal Wire for Construction Strong & Corrosion-Resistant

NewsJun.09,2025