wrz . 06, 2024 17:08 Back to list

Gabion Welded Wire Mesh Factories - Quality Solutions for Retaining Walls and Erosion Control

The Rise of Gabion Welded Wire Mesh Factories

In recent years, the construction and landscaping industries have increasingly turned to gabion welded wire mesh as a versatile solution for various applications. Gabion structures, which are essentially wire mesh cages filled with stones or other materials, provide stability, environmental protection, and aesthetic appeal. The growing demand for these structures has led to the establishment of numerous gabion welded wire mesh factories around the world, revolutionizing the way these essential materials are produced.

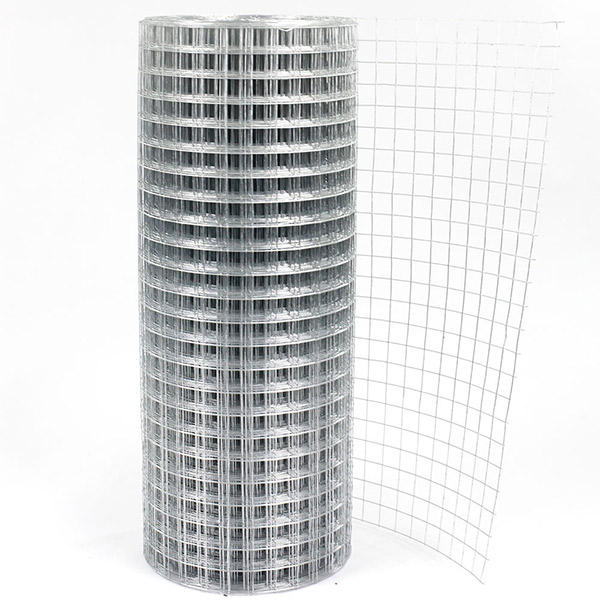

Gabion welded wire mesh is primarily made from steel, which is coated with zinc or other protective materials to enhance its durability and resistance to corrosion. This wire mesh is woven or welded together, creating robust structures that can withstand the elements, making it ideal for various applications such as retaining walls, riverbank protection, hillside stabilization, and decorative landscaping.

The production process of gabion welded wire mesh differs from traditional wire mesh manufacturing. Factories now employ advanced technologies and automated machinery to ensure precision and efficiency in their output. Automated welding machines create uniform, high-quality welded joints that enhance the strength of the mesh. This innovation not only speeds up production times but also reduces the likelihood of defects, ensuring a consistent product on the market.

gabion welded wire mesh factories

One of the significant advantages of gabion welded wire mesh factories is their ability to customize products to meet specific client needs. By employing sophisticated design software, manufacturers can create gabions of various sizes and designs. This customization provides architects and engineers with the flexibility to integrate gabion solutions into their projects seamlessly. Whether for commercial, residential, or infrastructural applications, tailored gabions can address unique challenges presented by different environments.

Moreover, the environmental benefits associated with gabion structures cannot be overlooked. The use of natural stones as fill material promotes sustainability, as it often utilizes locally sourced resources, reducing transportation costs and carbon footprints. This eco-friendly aspect makes gabion welded wire mesh an attractive option for environmentally conscious consumers and regulatory bodies.

As the demand for gabion welded wire mesh continues to rise, factories are also focusing on sustainable practices in their operations. Many are incorporating recycling initiatives, utilizing environmentally friendly materials, and adhering to strict environmental regulations. These efforts contribute not only to the reduction of waste but also bolster the factories' reputations in a market that increasingly values sustainability.

In conclusion, gabion welded wire mesh factories are at the forefront of a growing industry that combines innovation, customization, and sustainability. As these factories expand and advance their technologies, they play an essential role in meeting the demands of modern construction and landscaping projects. By providing high-quality, durable, and versatile products, they contribute to creating functional and aesthetically pleasing environments while respecting the principles of environmental stewardship. The future of gabion welded wire mesh seems bright, with increased integration into construction practices and a continued emphasis on sustainable solutions.

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025