gru . 21, 2024 02:53 Back to list

black iron wire black annealed wire manufacturer

Understanding Black Iron Wire and Its Manufacturing Process

Black iron wire, particularly black annealed wire, is a popular product in various industries due to its strength, flexibility, and corrosion resistance. This wire is extensively used in construction, fencing, and manufacturing applications. In this article, we will explore the characteristics of black iron wire, the manufacturing process, and the advantages it offers, particularly focusing on black annealed wire.

What is Black Iron Wire?

Black iron wire is made from low-carbon steel and is characterized by its dark, matte finish. This type of wire is often used in the production of wire products, including nails, staples, and various types of fencing. The wire is typically coated with a layer of iron oxide, which provides it with its distinctive black color. The manufacturing process involves drawing the steel into wire, which can then be annealed to enhance its properties.

The Manufacturing Process

The manufacturing of black annealed wire begins with the sourcing of high-quality low-carbon steel. The steel is first processed into wire rods. These rods are heated and then drawn through a series of dies to reduce their diameter and improve their mechanical properties. The drawing process also plays a crucial role in determining the wire's tensile strength and flexibility.

Once the wire is drawn to the desired specifications, the next step is annealing. Annealing is a heat treatment process that involves heating the wire to a specific temperature and then cooling it at a controlled rate. This process relieves internal stresses, increases ductility, and enhances the wire's overall strength. As a result, black annealed wire has a softer, more pliable nature, making it easier to work with in various applications.

After annealing, the wire is coated with a layer of oil or another protective substance to prevent rust and corrosion

. The final step involves cutting the wire into desired lengths, packaging, and labeling it for distribution to manufacturers and consumers.black iron wire black annealed wire manufacturer

Advantages of Black Annealed Wire

1. Enhanced Flexibility and Workability One of the prime benefits of black annealed wire is its flexibility. The annealing process softens the wire, allowing it to be easily bent, twisted, and manipulated for various applications. This makes it especially valuable in fields like crafting and construction, where adaptability is crucial.

2. Corrosion Resistance Although black iron wire has a natural propensity to rust, the annealing process and protective coatings significantly enhance its resistance to corrosion. This is particularly beneficial in outdoor applications where exposure to the elements is common.

3. Cost-Effectiveness Compared to other types of wire, black annealed wire is often more affordable. Its manufacturing process allows for mass production, which keeps costs low without sacrificing quality. This makes it an attractive option for many industries, particularly in budget-sensitive projects.

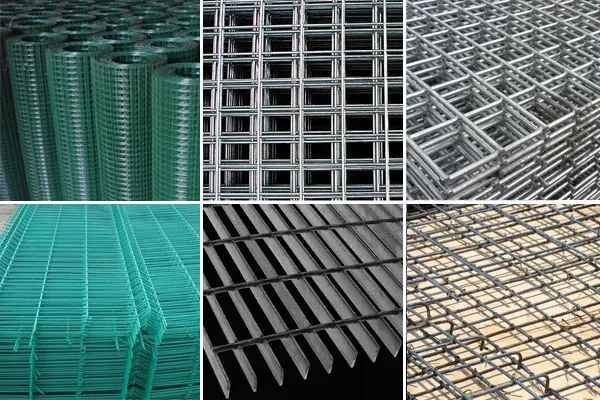

4. Versatility Black annealed wire can be used in a multitude of applications, ranging from agricultural fencing and baling wire to scaffolding and mesh production. Its versatility ensures that it meets the diverse needs of various industries effectively.

5. Strong Bonding Properties The wire’s ability to be easily twisted and bound together makes it ideal for crafting and construction applications. It forms strong bonds that can withstand tension, providing stability and support in structures.

Conclusion

Black iron wire, especially in its annealed form, presents numerous advantages for a variety of applications across different industries. Its flexibility, cost-effectiveness, and versatility make it a vital component in construction, manufacturing, and design. As manufacturers continue to refine the production processes, we can expect innovations that enhance the performance and application scope of black annealed wire, ensuring its relevance in an ever-evolving market. Understanding the properties and benefits of this material will help consumers and businesses make informed decisions when sourcing wire for their particular needs.

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025