ਨਵੰ. . 09, 2024 19:20 Back to list

Welded Wire Mesh Production Equipment from Leading Manufacturer for Quality Mesh Solutions

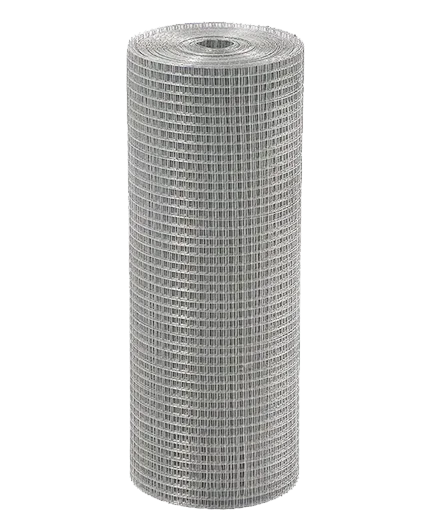

The Importance of Welded Wire Machine Mesh Manufacturing

In the modern industrial landscape, welded wire mesh plays a critical role in a variety of applications, ranging from construction to agriculture. As demand continues to rise, the significance of effective and innovative welded wire machine mesh factories cannot be overstated. This article explores the production process, applications, and benefits of welded wire mesh, shedding light on why these factories are essential to multiple industries.

Understanding Welded Wire Mesh

Welded wire mesh is a grid-like structure created by welding together wires at their intersections. The process starts with high-quality steel or galvanized wire, which is cut and arranged into a specific layout. These wires are then subjected to extreme heat at the points of intersection, ensuring a robust and durable product. The end result is a mesh that can withstand varying degrees of pressure and tension, making it suitable for numerous uses.

The Manufacturing Process

The production of welded wire mesh involves several key stages

1. Wire Preparation Raw materials are selected and prepared. The type of wire used can significantly impact the durability and performance of the final product.

2. Mesh Configuration The wires are arranged in a grid pattern. This can be customized according to the specific requirements of the client, including mesh size and wire gauge.

3. Welding Using advanced welding machines, the wires are fused together at the appropriate points. This step is crucial as it determines the strength and integrity of the mesh.

4. Finishing Once welded, the mesh may undergo additional treatments such as galvanization or coating to enhance its resistance to corrosion and wear.

5. Quality Control Rigorous testing ensures that the mesh meets industry standards and client specifications. This includes checks for tensile strength, mesh dimensional accuracy, and surface finish quality.

6. Packaging and Distribution After passing quality checks, the welded wire mesh is packaged for shipment, ready to meet the established demand in various markets.

Applications of Welded Wire Mesh

welded wire machine mesh factory

Welded wire mesh finds widespread use in several sectors

- Construction In the construction industry, welded wire mesh is often used as reinforcement for concrete slabs, walls, and ceilings. Its strength helps to enhance the structural integrity and durability of buildings.

- Fencing Welded wire mesh is a popular choice for fencing in residential and commercial properties. Its rigidity and ability to deter intrusion make it an effective security measure.

- Agriculture Farmers utilize welded wire mesh for animal enclosures, crop protection, and trellising plants. The mesh provides a physical barrier that is both strong and reliable.

- Industrial Applications In manufacturing and logistics, welded wire mesh is used for shelving, racks, and storage units. Its versatility allows for the construction of various industrial setups.

The Benefits of Using Welded Wire Mesh

1. Durability One of the primary advantages of welded wire mesh is its long lifespan. With proper maintenance, it can last for many years, even in harsh environments.

2. Customizability Welded wire mesh can be tailored to meet specific client needs, from wire diameter to mesh size, making it suitable for a wide range of applications.

3. Cost-Effective In comparison to alternative materials, welded wire mesh provides an economical solution without compromising on quality.

4. Easy Installation The lightweight nature of welded wire mesh allows for easier handling and installation, reducing labor costs and time.

5. Environmental Friendliness Many manufacturers are adopting eco-friendly practices by using recyclable materials and reducing waste during production, making welded wire mesh an environmentally responsible choice.

Conclusion

The welded wire machine mesh factory is a pivotal player in the production and distribution of welded wire mesh, serving various industries with effective solutions for their structural and fencing needs. The combination of advanced manufacturing techniques, quality materials, and rigorous testing ensures that the end products are reliable and efficient. As industries evolve and expand, the importance of resilient and versatile products like welded wire mesh remains indispensable, making these factories key contributors to modern industrial progress.

-

Heavy-Duty Welded Wire Mesh for Industrial Factories

NewsAug.04,2025

-

Chain Link Fence - Anping County Puersen | Durable, Versatile, Reliable

NewsAug.03,2025

-

Chain Link Fence: Durable, Versatile, and Reliable Fencing Solution|Galvanized Steel Fence Manufacturers

NewsAug.03,2025

-

Chain Link Fence-Galvanized Steel Fence Factory|Durable, Versatile, Cost-Effective

NewsAug.03,2025

-

Heavy-Duty Welded Wire Mesh for Industrial Factories

NewsAug.03,2025

-

Galvanized Steel Fence-Anping Puersen|Durable,Flexible

NewsAug.02,2025