ਦਸੰ. . 15, 2024 19:09 Back to list

PVC Coated Welded Wire Mesh Panel Manufacturer for Durable Fencing Solutions

PVC Coated Welded Wire Mesh Panel Factory A Comprehensive Insight

In recent years, the demand for durable and versatile fencing solutions has been on the rise, leading to an increased focus on welded wire mesh panels, particularly those that are PVC coated. The combination of welded wire technology with the protective benefits of PVC coating results in products that are not only strong and reliable but also aesthetically pleasing. This article delves into the intricacies of PVC coated welded wire mesh panels, highlighting their manufacturing processes, benefits, applications, and the significance of factories in ensuring quality production.

Understanding PVC Coated Welded Wire Mesh Panels

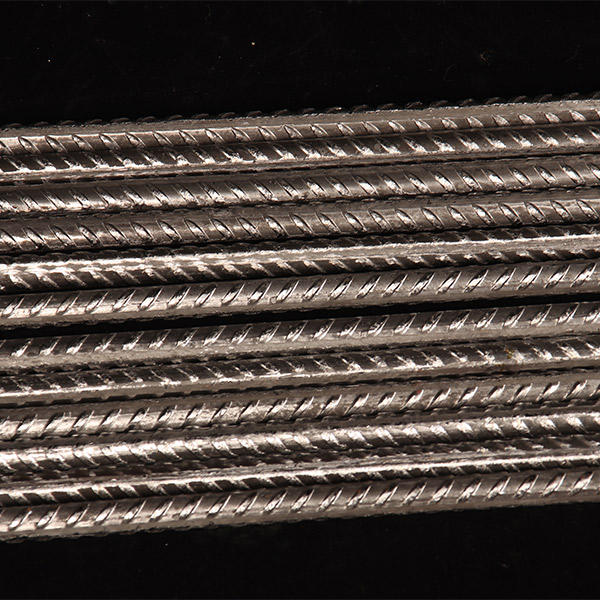

PVC coated welded wire mesh panels are essentially grids made from steel wires that are welded together at intersections, creating a robust framework. Post-welding, these panels are coated with PVC (polyvinyl chloride), which serves as a protective layer against rust, corrosion, and other environmental damages. The PVC coating also enhances the visual appeal of the panels, with various color options available to suit different design preferences.

Manufacturing Process

The manufacturing of PVC coated welded wire mesh panels involves several key steps

1. Wire Preparation High-quality steel wires are selected based on their gauge and tensile strength. These wires are cleaned and prepped for welding.

2. Welding The prepared wires are welded together using resistance welding techniques, which ensure strong joints and the structural integrity of the mesh panel. The welding can be done in various configurations depending on the desired mesh pattern.

3. Coating Once welded, the panels are coated with PVC, typically through a dipping or electrostatic spraying method. The PVC layer is applied uniformly to ensure optimal protection and durability.

4. Curing The coated panels are cured in an oven, allowing the PVC to set properly, thus enhancing adherence to the steel frame.

5. Quality Control After curing, each panel undergoes rigorous quality checks to assess the weld strength, coating uniformity, and overall aesthetics before packaging.

Benefits of PVC Coated Welded Wire Mesh Panels

pvc coated welded wire mesh panel factory

2. Corrosion Resistance The PVC coating protects the underlying steel from rust and corrosion, making these panels suitable for outdoor applications where exposure to moisture is a concern.

3. Aesthetic Appeal Available in a variety of colors, PVC coated panels blend seamlessly into various landscapes, making them a popular choice for residential and commercial properties alike.

4. Versatility These panels can be used in various applications, including fencing for gardens, parks, industrial premises, and agricultural fields, offering an effective solution for protection and boundary demarcation.

5. Low Maintenance Unlike untreated wire mesh, PVC coated panels require minimal upkeep. A periodic cleaning is usually sufficient to maintain their appearance and functionality.

Applications

The applications of PVC coated welded wire mesh panels are vast and varied. They are commonly used in

- Agricultural Fencing Protecting crops and livestock from intruding animals. - Security Fencing Securing industrial sites, construction areas, and sensitive infrastructures. - Gates and Barriers Creating entry points in commercial and residential properties. - Safety Mesh Ensuring safety in construction sites and factories.

The Role of Factories

The factory’s role in the production of PVC coated welded wire mesh panels is pivotal. A reputable factory employs advanced machinery, skilled labor, and adheres to strict quality standards throughout the manufacturing process. This ensures that each product meets industry specifications and customer expectations. Moreover, investment in research and development allows factories to innovate and improve their manufacturing methods, resulting in even better products.

Conclusion

In conclusion, PVC coated welded wire mesh panels are a testament to the advancement in fencing technology. Their durability, aesthetic appeal, and versatility make them an excellent choice for various applications. As the demand for these panels continues to grow, the significance of factories in delivering high-quality products will remain paramount in the industry. Whether for security, agricultural, or aesthetic purposes, PVC coated welded wire mesh panels represent a smart investment in safety and style.

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025