ਅਕਤੂਃ . 10, 2024 00:04 Back to list

green pvc coated wire manufacturer

A Comprehensive Overview of Green PVC Coated Wire Manufacturing

In today’s fast-paced industrial environment, the demand for durable and versatile materials is higher than ever. Among these, green PVC coated wire has emerged as a popular choice due to its excellent insulation properties, corrosion resistance, and aesthetic appeal. The manufacturing process of green PVC coated wire plays a crucial role in producing a superior product that meets the diverse needs of various industries, from construction to agriculture.

What is PVC Coated Wire?

PVC, or Polyvinyl Chloride, is a synthetic plastic polymer that is widely used in various applications. When it comes to wire coatings, PVC is favored for its ability to enhance the wire's durability and resistance to environmental factors. Green PVC coated wire is essentially a base wire coated with a layer of green PVC, providing both functional and decorative benefits. The green color is often chosen for its suitability in outdoor environments, allowing the wire to blend seamlessly with natural surroundings.

The Manufacturing Process

The manufacturing of green PVC coated wire involves several key steps that ensure the final product meets stringent quality standards

1. Wire Preparation The process begins with the selection of high-quality base wire, typically made from materials like steel or aluminum. The wire is cleaned to remove any dirt or impurities which could affect the adhesion of the PVC coat.

2. Annealing In some cases, the wire undergoes an annealing process to relieve stress and enhance its flexibility. This step is crucial for achieving the desired mechanical properties in the coated wire.

3. Coating The most critical stage of production is the coating process. The clean, prepared wire is submerged in a heated environment where PVC pellets are melted and applied as a coating. The temperature and duration of this process are meticulously controlled to ensure an even and uniform coating. The green pigment is added to the PVC to achieve the desired color, providing UV resistance to prevent fading over time.

green pvc coated wire manufacturer

4. Cooling After coating, the wire needs to cool down gradually. This process solidifies the PVC layer, ensuring a strong bond with the wire underneath.

5. Quality Control Before packaging, the coated wire undergoes rigorous quality control tests. This includes checking the thickness of the PVC layer, tensile strength, and overall durability. Manufacturers may also perform tests to assess resistance to environmental factors such as moisture, heat, and UV exposure.

6. Cutting and Packaging Once the wire has passed quality inspections, it is cut to specific lengths, wound into coils or spools, and prepared for shipment. Proper packaging is essential to protect the wire during transportation and handling.

Applications of Green PVC Coated Wire

The versatility of green PVC coated wire means it can be used in a variety of applications

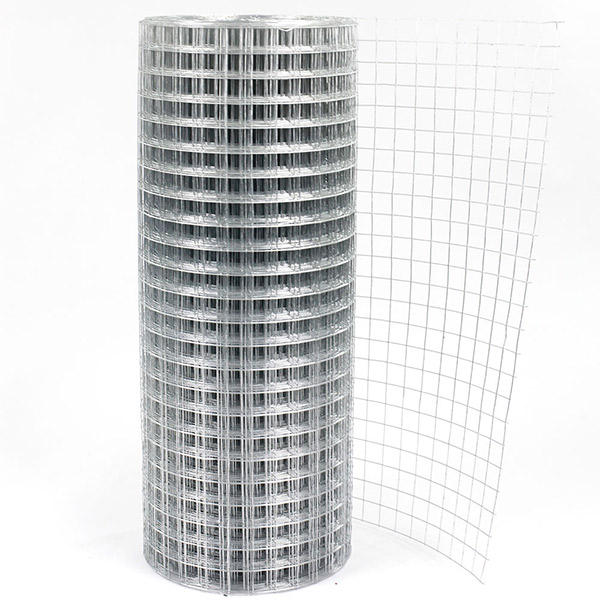

- Fencing Due to its corrosion resistance and aesthetic appeal, green PVC coated wire is often used for fencing solutions in gardens, parks, and agricultural fields. - Electrical Wiring The insulation properties of PVC make it suitable for electrical applications, where safety and durability are paramount. - Construction In construction, the wire is used for reinforcement, supporting structures, or as part of wire mesh. - Crafting and DIY Projects Many hobbyists and crafters use green PVC coated wire for various projects, benefiting from its flexibility and ease of use.

Conclusion

Green PVC coated wire is a valuable material that has found a place in numerous industries due to its durability, aesthetic qualities, and resistance to environmental factors. The manufacturing process is a blend of art and science, ensuring that every product meets the highest standards of quality. As industries continue to evolve, the demand for high-quality green PVC coated wire is expected to grow, making it a pivotal element in modern manufacturing and construction. With ongoing advancements in material science and production techniques, the future of green PVC coated wire looks promising, opening doors to new applications and innovations.

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025