ਦਸੰ. . 02, 2024 02:41 Back to list

4mm Galvanized Iron Wire Manufacturer for Quality Industrial Applications

The Significance of 4mm GI Wire Factories in Modern Construction

In the realm of modern construction and infrastructure development, materials play a pivotal role in determining the strength, durability, and overall quality of structures. Among the myriad of materials available, galvanized iron (GI) wire has gained substantial popularity owing to its remarkable properties. The 4mm gauge GI wire, in particular, stands out for its versatility and robustness. This article delves into the significance of 4mm GI wire factories and their role in meeting the growing demands of various sectors.

Understanding Galvanized Iron Wire

Galvanized iron wire is made from iron that has been coated with a layer of zinc to prevent rust and corrosion. This process not only enhances the wire's lifespan but also improves its strength, making it suitable for a range of applications. The 4mm diameter of the wire strikes an ideal balance between flexibility and firmness, allowing it to be used in numerous construction-related tasks. Its sturdiness makes it ideal for fencing, reinforcing concrete, and supporting various structures.

The Manufacturing Process of 4mm GI Wire

The manufacturing process of 4mm GI wire involves several crucial steps. The process begins with high-quality steel being drawn into wire of the desired diameter. Once the wire has been produced, it undergoes the galvanization process, where it is submerged in molten zinc. This zinc coating acts as a barrier against moisture and oxygen, thereby preventing rust. Factories specializing in 4mm GI wire often implement high levels of automation and quality control, ensuring that each coil of wire meets industry standards.

Applications in Various Sectors

The applications of 4mm GI wire are as diverse as they are essential. In agriculture, it is commonly used for fencing to keep livestock contained and to protect crops from wild animals. Its durability makes it a frequent choice for trellises and plant support systems as well.

In the construction industry, 4mm GI wire serves multiple purposes. It is frequently utilized in the production of concrete reinforcement grids, providing enhanced structural integrity to buildings and infrastructure. Additionally, its properties make it suitable for securing construction sites, protecting materials from theft and vandalism. The wire is also utilized for various industrial needs including cable production, and as components in machinery.

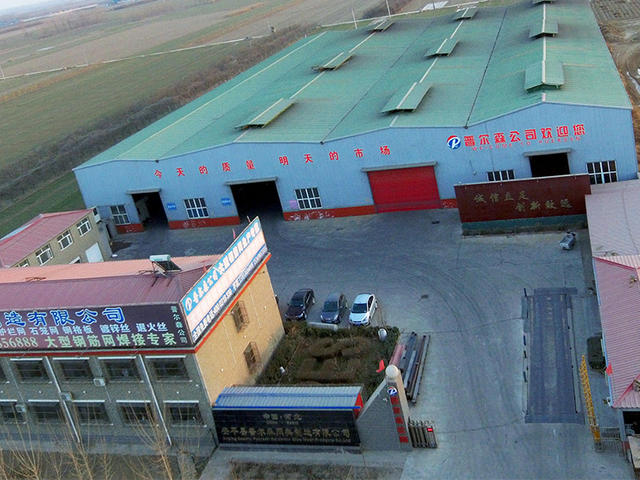

gi wire 4mm factory

Sustainability and Environmental Concerns

As society increasingly prioritizes sustainability, the role of factories producing 4mm GI wire is also evolving. Modern manufacturing techniques focus on reducing waste and energy consumption. Many factories now embrace eco-friendly practices, such as recycling scrap metal and using sustainable energy sources. Furthermore, the durability of GI wire reduces the frequency of replacements needed, which in turn lessens its environmental impact.

Economic Importance

The economic implications of 4mm GI wire factories cannot be understated. These facilities contribute significantly to local economies by creating jobs and fostering skill development. As construction and infrastructure projects grow globally, the demand for reliable and durable materials like GI wire is also on the rise. Factories that produce 4mm GI wire thus play a crucial role in the supply chain, ensuring that construction companies have access to high-quality materials.

Challenges Faced by Manufacturers

Despite the numerous benefits, manufacturers of 4mm GI wire face several challenges. Fluctuating raw material prices can affect production costs and profit margins. Additionally, increased competition from foreign manufacturers can pressure local factories, necessitating a focus on innovation and customer service to remain competitive. Furthermore, as environmental regulations become more stringent, factories must adapt their processes to meet these new standards, which can require significant investment.

Conclusion

In conclusion, 4mm GI wire factories are vital components of the construction and manufacturing industries. Their ability to produce high-quality, durable wire makes them indispensable for a variety of applications, from agricultural fencing to structural reinforcement in buildings. With a focus on sustainability and economic contribution, these factories are well-positioned to meet the demands of an evolving market. As the world continues to develop and modernize, the significance of 4mm GI wire and its manufacturing facilities will only increase, underscoring their relevance in our interconnected global landscape.

-

12mm Stainless Steel Wire Mesh for Industrial & Commercial Use Top Quality Factories & Manufacturers

NewsJun.24,2025

-

Black Annealed Wire Specification - High Quality & Custom Options from Leading Factories, Suppliers, Manufacturers

NewsJun.10,2025

-

High-Quality 18 Gauge Black Steel Wire Reliable Factories & Suppliers

NewsJun.10,2025

-

Chain Link Fence Gates - Durable & Secure Access Solutions

NewsJun.10,2025

-

Premium Cold Rolled Steel Bar Supplier High Strength & Precision

NewsJun.10,2025

-

Galvanized Wire Brick Force Mesh - Corrosion Resistant

NewsJun.09,2025