ਸਤੰ. . 29, 2024 08:39 Back to list

Top Manufacturers of Cold Drawn Spring Wire for Quality Production

The Importance of Cold Drawn Spring Wire Manufacturers

Cold drawn spring wire is a crucial component in the manufacturing of springs and other wire products across various industries. The process of cold drawing enhances the mechanical properties of the wire, including its strength, ductility, and overall performance. Manufacturers specializing in cold drawn spring wire play a vital role in providing high-quality materials essential for the production of reliable and durable springs.

Understanding Cold Drawing Process

Cold drawing is a manufacturing process where wire is pulled through a series of dies at room temperature. This technique not only reduces the diameter of the wire but also increases its tensile strength through strain hardening. As the wire is drawn, any imperfections are minimized, resulting in a smooth, consistent product. The benefits of cold drawn spring wire include improved mechanical properties and enhanced surface finish, making it ideal for a wide range of applications.

Applications of Cold Drawn Spring Wire

Cold drawn spring wire is used in various applications, from automotive and aerospace industries to consumer goods. Its versatility means it can be found in products such as

1. Compression Springs Widely used in mechanical devices, compression springs help store mechanical energy and cushion impact in various applications, including automotive suspensions and industrial machinery.

2. Tension Springs These springs are designed to stretch and provide resistance against pulling forces. They are commonly found in applications requiring flexibility and durability.

3. Torsion Springs Operating on a twisting motion, torsion springs can be found in hatches, clips, and various other mechanisms that require rotational energy storage.

4. Wire Forms Cold drawn wire can be shaped into various forms, including brackets and supports that find applications in the construction and manufacturing sectors.

Choosing the Right Manufacturer

When selecting a cold drawn spring wire manufacturer, several factors should be considered to ensure the quality and reliability of the product

1. Material Quality The manufacturer should use high-grade raw materials. Common materials include stainless steel, music wire, and other alloys that ensure optimal performance.

cold drawn spring wire manufacturers

2. Technology and Equipment Advanced machinery and technology are essential for producing consistent and high-quality wire. The latest cold drawing techniques can lead to improved efficiency and product quality.

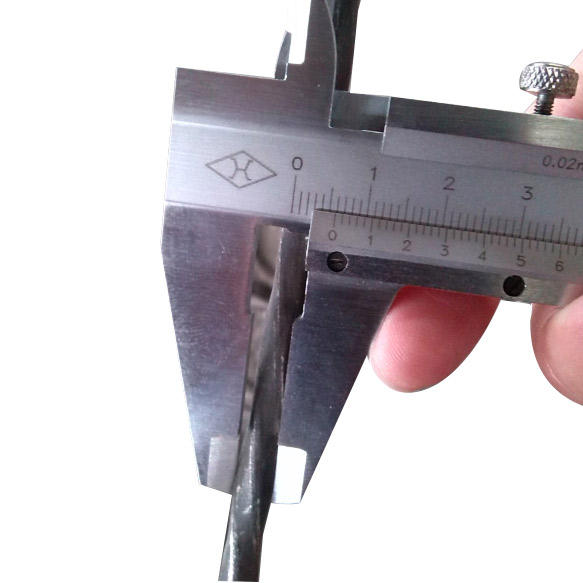

3. Quality Control A reputable manufacturer will have strict quality control measures in place, ensuring that every batch of wire meets specific standards. This can include tensile testing, surface inspection, and dimensional checks.

4. Custom Capabilities Many applications require specific wire sizes and characteristics. A good manufacturer will offer customization options to meet the unique needs of their clients.

5. Industry Experience Experienced manufacturers often have a better understanding of the industry standards and customer requirements, which can lead to a more reliable product.

Benefits of Working with Specialized Manufacturers

Collaborating with specialized cold drawn spring wire manufacturers can provide numerous advantages

- Expertise They possess in-depth knowledge about spring design and wire applications, ensuring that they can offer valuable insights and recommendations.

- Cost-Effectiveness By optimizing the production process, these manufacturers can often provide competitive pricing without compromising quality.

- Timely Delivery Established manufacturers are often capable of meeting tight deadlines, ensuring that production schedules are adhered to.

- Support and Service A specialized manufacturer will typically offer better customer service, assisting clients throughout the ordering and production process.

Conclusion

Cold drawn spring wire manufacturers are indispensable players in the manufacturing ecosystem. Their expertise in producing high-quality wire not only enhances the performance of springs but also contributes to the overall safety and efficiency of countless applications. As industries continue to evolve, the demand for high-quality spring wire will only increase, making it essential for manufacturers to uphold stringent standards and embrace innovation to meet customer needs. Whether in automotive, aerospace, or general manufacturing, the importance of collaborating with skilled cold drawn spring wire manufacturers cannot be overstated.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025