Sep . 19, 2024 03:14 Back to list

wire panel welded wire mesh factory

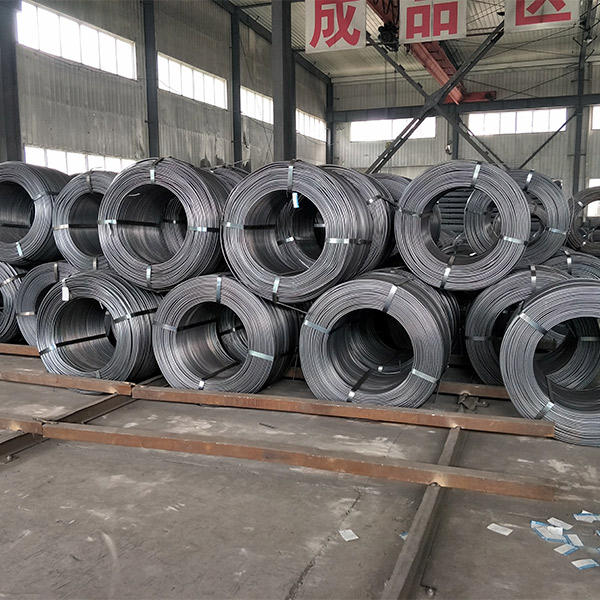

The Significance of Welded Wire Mesh in Modern Manufacturing

In the realm of industrial manufacturing, welded wire mesh has become an indispensable material, known for its strength, versatility, and comprehensive applications

. The rise of welded wire mesh factory production has made this essential product widely available, catering to various sectors including construction, agriculture, and fencing.Welded wire mesh is produced by the intersection of horizontal and vertical wires that are electrically fused at their joints. This method not only ensures a robust and uniform structure but also enhances the overall integrity of the product. The array of wire sizes, spacing configurations, and coatings available allows manufacturers to customize welded wire mesh to meet specific requirements for diverse applications. For instance, in construction, it is used for concrete reinforcement, providing added strength and durability to slabs, walls, and foundations.

One of the most significant advantages of welded wire mesh is its exceptional strength-to-weight ratio. The manufacturing process employs high-quality steel, ensuring that the resulting mesh is lightweight yet strong. This adaptability makes it suitable for various hefty applications without adding unnecessary weight to the structure. Moreover, its resistance to corrosion, particularly when galvanized, extends its lifespan and reduces maintenance costs, a critical factor for any manufacturing process.

wire panel welded wire mesh factory

The versatility of welded wire mesh extends beyond construction. In agriculture, it is used for livestock enclosures, fencing, and even in the design of trellis systems for plants. The open design allows plants to receive adequate sunlight and air, promoting healthy growth while providing a robust structure for animals. This adaptability showcases the invaluable role that welded wire mesh plays in supporting agricultural productivity.

Additionally, welded wire mesh factories are equipped with advanced technology that enhances production efficiency and quality control. Automated welding machines ensure that each piece of mesh is consistent in strength and quality, reducing the risk of defects. Factories implementing stringent quality assurance processes can guarantee that their products meet the required international standards, providing customers with reliable and durable materials.

With increasing global demand for high-quality welded wire mesh, many factories focus on innovating sustainable manufacturing practices. By utilizing recyclable materials and reducing waste during production, these manufacturers not only contribute to environmental conservation but also appeal to the growing market of environmentally conscious consumers.

In conclusion, the significance of welded wire mesh in modern manufacturing cannot be overstated. Its combination of strength, versatility, and cost-effectiveness positions it as a crucial material across various sectors. The advancements in factory production processes are paving the way for more sustainable and efficient manufacturing practices, ensuring that welded wire mesh remains a staple in the industry for years to come. As we continue to innovate and adapt, the role of welded wire mesh in improving operational efficiency and sustainability will only grow in importance, making it a key component in the future of manufacturing.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025