Nov . 24, 2024 05:55 Back to list

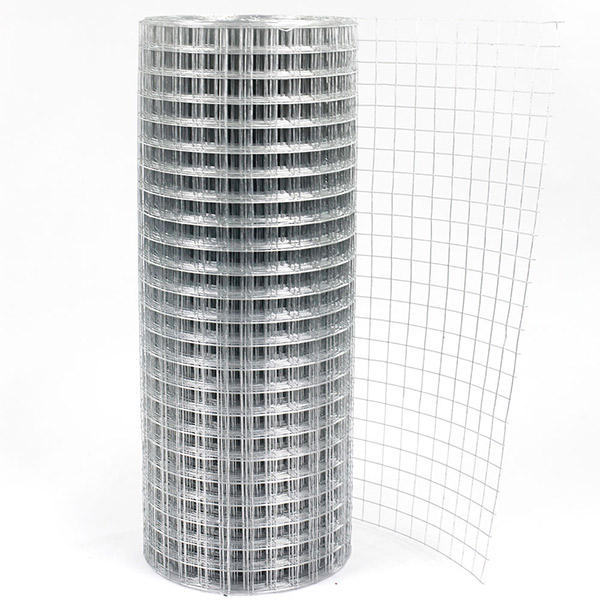

welded wire mesh 9 gauge factory

The Significance of Welded Wire Mesh in Modern Construction A Focus on 9 Gauge Factory Production

Welded wire mesh is an essential component in various construction applications, offering durability, strength, and versatility. Among the various gauges of welded wire mesh available, 9 gauge is particularly popular due to its balance of strength and flexibility. This article explores the significance of 9 gauge welded wire mesh produced in factories, analyzing its manufacturing process, applications, and benefits.

Manufacturing Process

The production of 9 gauge welded wire mesh begins with high-quality steel wire, which is drawn to the desired gauge. The term gauge refers to the thickness of the wire, with a lower number indicating a thicker wire. A 9 gauge wire is approximately 0.148 inches in diameter, providing superior strength compared to thinner alternatives. During manufacturing, the wires are arranged in a grid pattern and welded at each intersection using advanced machinery. This process ensures that the mesh is not only strong but also uniformly shaped and dimensionally consistent.

After welding, the mesh may undergo additional treatments such as galvanization or coating with protective layers. Galvanization involves coating the steel with zinc to enhance its corrosion resistance, making it suitable for outdoor applications. The result is a durable product that can withstand various environmental conditions, ensuring longevity and reliability.

Applications

welded wire mesh 9 gauge factory

The versatility of 9 gauge welded wire mesh makes it suitable for a wide range of applications. One common use is in concrete reinforcement. When embedded in concrete, the mesh helps distribute loads evenly, preventing cracking and enhancing the structural integrity of slabs, walls, and foundations. This is particularly important in industrial construction, where heavy loads and dynamic stresses are common.

In addition to reinforcement, 9 gauge mesh finds applications in fencing and enclosure systems. Its strength makes it ideal for securing properties, livestock, and industrial sites. The mesh can be easily installed as fencing panels or used to create cages for animals in agricultural settings. Its durability ensures that it can withstand impacts and resist wear over time.

Benefits

The choice of 9 gauge welded wire mesh comes with several advantages. First and foremost, its strength provides peace of mind, especially in construction projects where safety is paramount. The uniformity of the mesh also facilitates easier installation and consistent performance.

Moreover, the cost-effectiveness of 9 gauge welded wire mesh is another significant benefit. While the initial investment might be slightly higher compared to thinner gauges, its longevity and reduced maintenance requirements translate into cost savings over time.

In conclusion, the production of 9 gauge welded wire mesh in factories plays a vital role in modern construction. Its exceptional strength, versatility, and cost-effectiveness ensure it remains a preferred choice for various applications. Whether used in concrete reinforcement or fencing solutions, 9 gauge welded wire mesh continues to be an indispensable resource for builders and engineers looking for reliable construction materials.

-

High Quality Roll Welded Wire Mesh for Concrete Reinforcing BWG22 Galvanized Mesh Rolls Factory Direct

NewsJul.04,2025

-

High Quality Deformed Steel Bars China - Leading Manufacturers & Suppliers

NewsJul.04,2025

-

12mm Stainless Steel Wire Mesh for Industrial & Commercial Use Top Quality Factories & Manufacturers

NewsJun.24,2025

-

Black Annealed Wire Specification - High Quality & Custom Options from Leading Factories, Suppliers, Manufacturers

NewsJun.10,2025

-

High-Quality 18 Gauge Black Steel Wire Reliable Factories & Suppliers

NewsJun.10,2025

-

Chain Link Fence Gates - Durable & Secure Access Solutions

NewsJun.10,2025