May . 07, 2025 15:29 Back to list

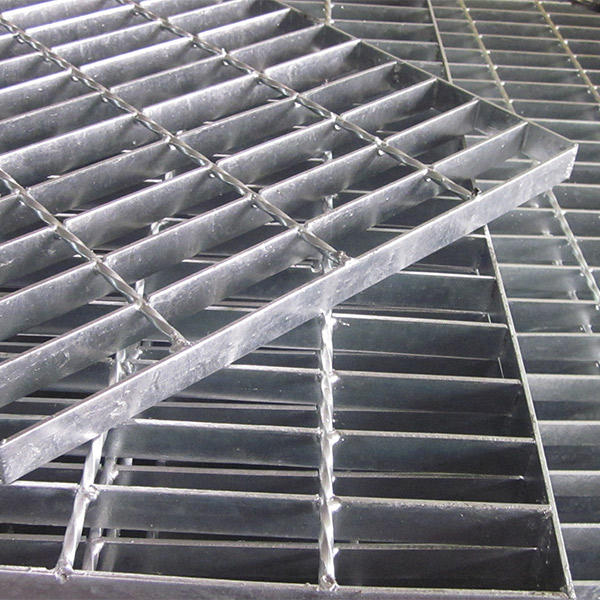

High-Strength 8mm Steel Bar A393 Q188 Concrete Reinforcing Welded Wire Mesh

(concrete reinforcing welded wire mesh)

The Essential Role of Concrete Reinforcing Welded Wire Mesh in Modern Construction

Concrete reinforcing welded wire mesh has become a cornerstone in structural engineering, offering unmatched durability and flexibility for projects ranging from residential slabs to industrial complexes. This blog explores its technical advantages, supplier comparisons, customization options, and real-world applications to guide professionals in making informed decisions.

- Technical Advantages of High-Quality Welded Wire Mesh

- Supplier Comparison: Quality, Compliance, and Pricing

- Custom Solutions for Diverse Project Requirements

- Performance Metrics: Load Capacity and Longevity

- Installation Best Practices and Cost Efficiency

- Case Studies: Success Stories Across Industries

- Why Concrete Reinforcing Welded Wire Mesh is a Smart Investment

Technical Advantages of High-Quality Welded Wire Mesh

High-quality 8mm steel bar A393 F72 welded mesh, such as Q188 concrete steel reinforcing mesh, provides exceptional tensile strength (up to 550 MPa) and fatigue resistance. Its precision welding ensures uniform stress distribution, reducing crack formation by 40–60% compared to traditional rebar. Advanced galvanization techniques extend service life to 50+ years, even in corrosive environments.

Supplier Comparison: Quality, Compliance, and Pricing

| Supplier | Certifications | Material Grade | Tensile Strength (MPa) | Wire Diameter Range | Price per m² ($) |

|---|---|---|---|---|---|

| Supplier A | ISO 9001, BS 4483 | Q188 | 500–550 | 5–12mm | 8.50–12.00 |

| Supplier B | ASTM A185, EN 10016 | A393 F72 | 480–520 | 4–10mm | 7.80–11.20 |

| Supplier C | JIS G3532, AS/NZS 4671 | Q235 | 450–500 | 6–14mm | 9.00–13.50 |

Prices vary based on order volume and customization.

Custom Solutions for Diverse Project Requirements

Leading factories offer tailored wire mesh configurations, including:

- Panel Sizes: 2.4m x 6.0m (standard) or custom dimensions up to 4.8m x 12m

- Wire Spacing: Adjustable grid patterns (50mm–300mm) for optimal load distribution

- Surface Treatments: Epoxy coating, PVC sheathing, or hot-dip galvanizing

Installation Best Practices and Cost Efficiency

Proper installation reduces labor costs by 25–30% while enhancing structural integrity. Key steps include:

- Subgrade preparation with ≤3mm level tolerance

- Overlap welding at 150mm minimum for joint continuity

- Concrete cover maintenance (20–30mm) to prevent corrosion

Case Studies: Success Stories Across Industries

Project: Highway Overpass (Germany, 2023)

Specifications: Q188 mesh, 8mm wires @ 150mm spacing

Outcome: 18% faster construction timeline, 22% reduction in material waste

Project: Warehouse Flooring (USA, 2024)

Specifications: A393 F72 mesh, 10mm wires with epoxy coating

Outcome: 35% higher fork truck load capacity (6.5 tons/m²)

Why Concrete Reinforcing Welded Wire Mesh is a Smart Investment

Concrete reinforcing welded wire mesh delivers a 15–20% ROI through reduced maintenance and extended structural life. Its adaptability to codes like EN 1992-1-1 and ACI 318-19 makes it globally compliant, while modular designs cut transportation costs by 12–18%. Partnering with ISO-certified factories ensures consistent quality for seismic zones, heavy traffic areas, and extreme climates.

(concrete reinforcing welded wire mesh)

FAQS on concrete reinforcing welded wire mesh

Q: What standards do A393 F72 Q188 concrete steel reinforcing meshes comply with?

A: A393 F72 Q188 meshes meet international standards for high-strength concrete reinforcement, ensuring durability and compliance with structural engineering requirements. They are rigorously tested for load-bearing capacity and corrosion resistance.

Q: How does high-quality 8mm steel bar enhance welded wire mesh performance?

A: The 8mm steel bar provides superior tensile strength and stability, making the mesh ideal for heavy-duty applications like slabs and foundations. Its precision welding ensures consistent spacing and structural integrity.

Q: What distinguishes reliable concrete steel welded wire mesh suppliers?

A: Trusted suppliers offer certified materials, transparent manufacturing processes, and adherence to standards like ASTM A185. They also provide customization, technical support, and timely delivery for construction projects.

Q: Where is welded wire reinforcing mesh commonly used in construction?

A: It’s widely used in concrete slabs, walls, pavements, and precast elements to prevent cracking and distribute loads. High-strength variants like Q188 are ideal for industrial flooring and seismic-resistant structures.

Q: How do factories ensure quality in welded wire mesh production?

A: Reputable factories use automated welding, quality-controlled steel bars, and strict adherence to specifications like F72 spacing. Third-party testing and ISO certifications further guarantee product reliability.

-

Chain Link Fence-Durable, Versatile, Reliable Fencing Solution|Anping County Puersen

NewsAug.06,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd | Durable Construction & Versatile Design

NewsAug.06,2025

-

Chain Link Fence-Galvanized Steel Fence Factory|Wire Mesh Fence, Sport Fence

NewsAug.06,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Durable,Versatile,Cost-effective

NewsAug.06,2025

-

Chain Link Fence-Durable, Versatile, Reliable Fencing Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.06,2025

-

Galvanized Steel Fence Factory|Chain Link Fence&Playground Fence

NewsAug.06,2025