Oct . 30, 2024 13:43 Back to list

16 gauge black annealed tie wire factory

Understanding 16 Gauge Black Annealed Tie Wire A Factory Perspective

In the realm of construction and metalworking, the materials chosen can significantly influence the outcome of a project. Among these materials, 16 gauge black annealed tie wire stands out for its versatility and reliability. Manufactured in specialized factories, this type of wire serves as a critical component for various applications, including fastening, tying, and supporting.

What is 16 Gauge Black Annealed Tie Wire?

The term 16 gauge refers to the wire's diameter, which is approximately 1.29 mm. This thickness strikes an ideal balance between strength and flexibility, making it suitable for handling diverse tasks. Black annealed denotes a specific treatment process where the wire is heated and then gradually cooled, resulting in a softer and more pliable product than its precursors. The black finish, a protective oxide layer, enhances corrosion resistance and provides a non-reflective surface, which can be vital in certain applications.

Production Process in Factories

The production of 16 gauge black annealed tie wire begins with high-quality steel wire rods. The manufacturing process typically involves several stages, including wire drawing, annealing, and packaging.

1. Wire Drawing In this initial stage, the thick wire rods are drawn through a series of dies, gradually reducing their diameter to the desired 16 gauge size. This process increases the wire's tensile strength.

16 gauge black annealed tie wire factory

2. Annealing After drawing, the wire undergoes annealing. This heat treatment process alleviates the rigidity induced by drawing, resulting in a softer, more ductile wire that can be easily handled and bent into shape.

3. Coating The wire is then subjected to a black oxide treatment, which provides a protective layer that guards against rust and enhances its appearance.

4. Packaging Finally, the finished product is wound into coils or packaged in spools, ready for distribution to various industries.

Applications in Industry

16 gauge black annealed tie wire finds its place in myriad applications. It is commonly used in construction for tying rebar together, in gardening for securing plants and trellises, and in the craft industry for creating various ornamental pieces. Its malleability makes it easy to twist and shape, enhancing its utility across multiple settings.

Conclusion

Manufactured with precision and care, 16 gauge black annealed tie wire stands as a testament to the sophistication of modern wire production. Its strength, flexibility, and corrosion resistance make it an essential tool in many industries, proving that even the simplest materials can have a profound impact on construction and craftsmanship. As factories continue to innovate in production methods, the future of tie wire remains promising, ensuring its relevance in both traditional and modern applications.

-

Chain Link Fence-Durable, Versatile, Reliable|Galvanized Steel,PVC Coated

NewsAug.05,2025

-

Chain Link Fence-Anping County Puersen|Galvanized Steel, Durability, Custom Solutions

NewsAug.05,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable&Versatile

NewsAug.05,2025

-

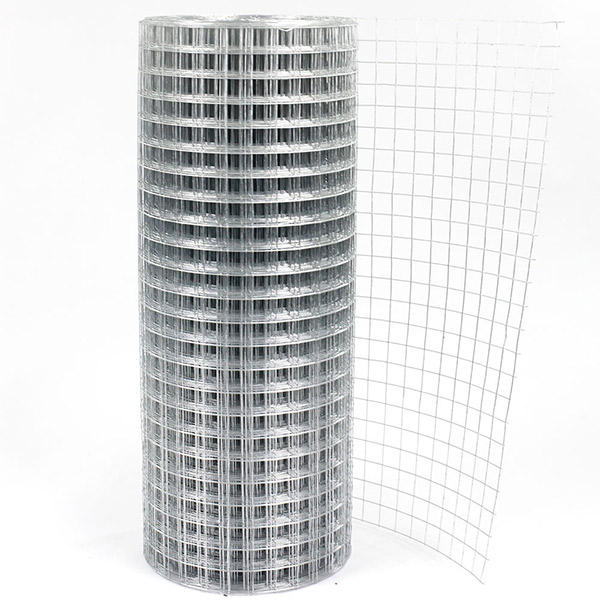

Welded Wire Mesh for Industrial Factories: Durable & Strong

NewsAug.05,2025

-

Heavy-Duty Welded Wire Mesh for Industrial Factories

NewsAug.04,2025

-

Chain Link Fence - Anping County Puersen | Durable, Versatile, Reliable

NewsAug.03,2025