sep . 22, 2024 13:43 Back to list

8 gauge galvanized wire manufacturer

Understanding 8% Gauge Galvanized Wire A Comprehensive Guide

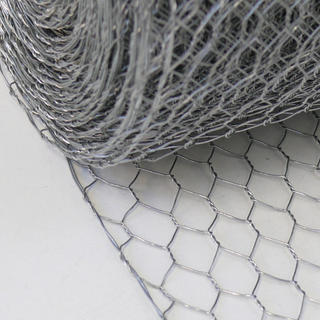

Galvanized wire is an essential material in various industries, known for its durability and resistance to corrosion. Among the different gauges available, the 8% gauge galvanized wire stands out due to its unique properties and applications. In this article, we will explore what 8% gauge galvanized wire is, its manufacturing process, and its potential uses.

What is 8% Gauge Galvanized Wire?

The term gauge refers to the thickness of the wire, with lower numbers indicating thicker wires. The 8% gauge is relatively thick, making it suitable for various heavy-duty applications. Galvanization is the process of coating steel wire with a layer of zinc to prevent rust and corrosion. This process not only enhances the wire's longevity but also ensures that it maintains its integrity even in harsh environmental conditions.

Manufacturing Process

The manufacturing of 8% gauge galvanized wire involves several key steps

1. Wire Drawing The first step in producing galvanized wire is wire drawing. During this phase, steel rods are pulled through a series of dies to achieve the desired thickness. For 8% gauge wire, the raw material must be meticulously drawn to ensure uniformity and strength.

8 gauge galvanized wire manufacturer

2. Pickling Following wire drawing, the wire undergoes a pickling process, where it is soaked in an acidic solution to remove any impurities and oxides. This step is crucial as it prepares the wire for effective galvanization.

3. Galvanization In this phase, the clean wire is coated with molten zinc through either hot-dipping or electro-galvanization. The hot-dip method typically results in a thicker coating, which is beneficial for applications exposed to severe weather conditions.

4. Cooling and Packaging After galvanization, the wire is cooled and then coiled into spools or cut into desired lengths for shipping. The final product is tested for quality to ensure it meets industry standards.

Applications

8% gauge galvanized wire has a wide range of applications, making it a popular choice among manufacturers and builders. Its strength and resistance to rust make it ideal for fencing, wire mesh, and construction work. Additionally, it is often used in agriculture for fencing livestock, as well as in the automotive industry for various components.

Conclusion

In conclusion, 8% gauge galvanized wire is a vital material that combines strength, versatility, and longevity. Its unique properties make it suitable for various applications across different industries. Understanding its manufacturing process can help stakeholders in the construction and manufacturing sectors make informed decisions, ensuring they select the right materials for their projects. Whether you need wire for fencing or construction, 8% gauge galvanized wire is a reliable option that stands the test of time.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025