Nov . 06, 2024 10:44 Back to list

Stud Bolt ASTM A193 B16 Specifications and Factory Production Insights

Understanding Stud Bolts ASTM A193 B16 Specifications and Factory Insights

When it comes to securing components in high-stress environments, stud bolts play a crucial role in various industrial applications. Among the numerous standards governing these fasteners, ASTM A193 B16 is one of the most significant, particularly for environments involving high temperature and pressure. This article delves into the essence of stud bolts, the specifics of ASTM A193 B16, and factors to consider when selecting a manufacturer or factory for these essential industrial components.

What Are Stud Bolts?

Stud bolts are cylindrical rods with threads on both ends, often utilized in conjunction with nuts to secure flanged connections. Their design allows for flexibility in applications, catering to different needs in various sectors, including oil and gas, power generation, and chemical processing. Stud bolts are highly favored for their strength, reliability, and ability to withstand extreme conditions.

ASTM A193 B16 An Overview

ASTM A193 is a standard specification that outlines the requirements for alloy and stainless steel bolting materials intended for high-temperature or high-pressure service. The B16 specification specifically focuses on nuts and bolts made from certain alloy steels, suitable for use in critical applications where failure is not an option.

Key Features of ASTM A193 B16

1. Material Composition ASTM A193 B16 stud bolts are primarily made from alloy steel that provides enhanced durability and resistance to thermal and mechanical shock. This is essential for applications where materials are subjected to extreme temperatures.

2. Mechanical Properties The specification outlines specific tensile strength, yield strength, and elongation requirements that these studs must meet. Typically, they exhibit excellent mechanical properties, ensuring that they can maintain integrity under significant load.

3. Temperature Resistance One of the most notable characteristics of B16 stud bolts is their ability to withstand high temperatures—typically up to 1,200°F (approximately 649°C). This makes them ideal for use in boiler and pressure vessels, as well as flanged joints subjected to thermal cycling.

4. Corrosion Resistance While the primary focus of ASTM A193 B16 is on high-temperature applications, many manufacturers also treat the bolts to enhance corrosion resistance. This can significantly extend the lifespan of the fasteners in aggressive environments.

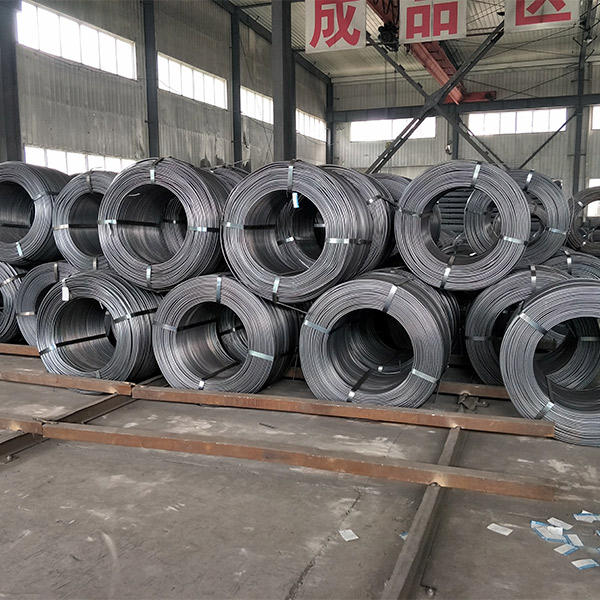

stud bolt astm a193 b16 factory

Selecting the Right Factory

When it comes to sourcing ASTM A193 B16 stud bolts, choosing the right factory is paramount to ensuring quality and performance. Here are some critical factors to consider

1. Certification and Standards Compliance Ensure that the factory is certified to produce ASTM A193 B16 stud bolts. They should have quality management systems in place and be capable of providing documentation that verifies compliance with relevant standards.

2. Manufacturing Capabilities The factory should possess modern manufacturing capabilities, including advanced machining and heat treatment processes that align with the specifications for producing high-quality stud bolts.

3. Quality Control Processes A reliable manufacturer will employ rigorous quality control processes throughout production to minimize defects and ensure that the final products meet all specified requirements.

4. Proven Track Record Researching the factory’s history and their client testimonials can provide insight into their reliability and the quality of their products. Established factories with a proven track record are often more trustworthy.

5. Technical Support An excellent factory will be willing to offer technical support and guidance regarding material selection, application specifications, and installation practices. This can be invaluable, particularly for complex projects.

6. Supply Chain Stability The ability of a factory to deliver products on time is crucial. Evaluate their supply chain processes and inventory management skills to ensure timely delivery that aligns with your project timelines.

Conclusion

Stud bolts, particularly those conforming to ASTM A193 B16 specifications, are indispensable in high-temperature and high-pressure applications across various industries. Understanding the significance of these fasteners and the manufacturing standards involved is critical for successful application. By carefully selecting a reliable factory that adheres to stringent quality and compliance standards, organizations can ensure the utmost performance and safety of their engineered systems. Investing time in these decisions will pay dividends in reliability and efficiency over time.

-

Chain Link Fence - Durable, Versatile Fencing Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.07,2025

-

Chain Link Fence: Durable, Versatile, Reliable Fencing Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.07,2025

-

Galvanized Steel Fence Factory: Durable & Rust-Proof Fencing

NewsAug.07,2025

-

Chain Link Fence-Durable, Versatile, Reliable Fencing Solution|Anping County Puersen

NewsAug.06,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd | Durable Construction & Versatile Design

NewsAug.06,2025

-

Chain Link Fence-Galvanized Steel Fence Factory|Wire Mesh Fence, Sport Fence

NewsAug.06,2025