Nov . 06, 2024 00:44 Back to list

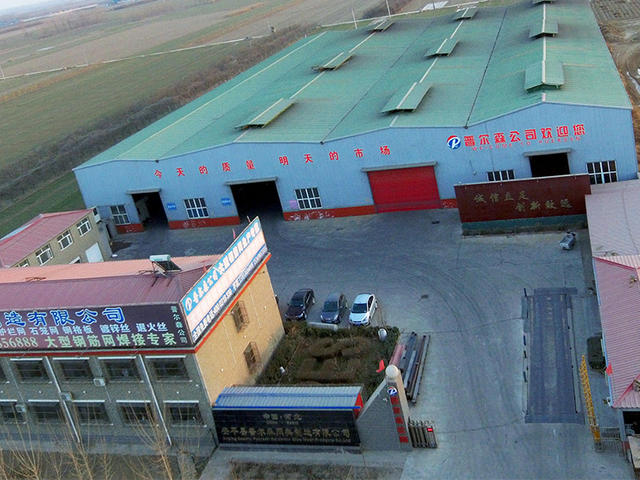

galvanized reinforced concrete net factory

Galvanized Reinforced Concrete Net Factory A Pioneering Solution for Modern Construction

In the realm of construction materials, galvanized reinforced concrete nets have emerged as an innovative solution that enhances the structural integrity and longevity of various architectural projects. As urbanization continues to rise globally, the demand for resilient building materials has never been greater, leading to the establishment of specialized factories dedicated to the production of these advanced nets.

Galvanized reinforced concrete nets are characterized by their unique combination of steel reinforcement and concrete applications. The galvanization process involves coating steel with a layer of zinc, which protects it from corrosion. This crucial step ensures that the steel maintains its strength and durability even in harsh environmental conditions. When combined with concrete, the result is a material that can withstand significant structural loads while offering flexibility in design and application.

A factory dedicated to the production of galvanized reinforced concrete nets usually follows strict quality control measures to ensure that the final products meet industry standards. From the selection of high-quality raw materials to the monitoring of manufacturing processes, every step is tailored to achieve excellence. The use of advanced machinery and technology enables these factories to produce nets of varying sizes and specifications, catering to a wide range of construction needs.

One of the primary applications of galvanized reinforced concrete nets is in the construction of bridges, buildings, and tunnels. These nets provide essential support and reinforcement, contributing to the overall strength and safety of the structure. Furthermore, they are often used in road construction and soil stabilization projects, where their flexibility allows for effective adaptation to different terrains and load conditions.

galvanized reinforced concrete net factory

The factory environment is also focused on sustainability. Many manufacturers are now implementing eco-friendly practices, such as recycling scrap metal generated during the production process, thereby reducing waste and minimizing the environmental footprint. Additionally, advancements in production technology enable energy-efficient methods that lower the overall carbon emissions associated with manufacturing.

The benefits of using galvanized reinforced concrete nets go beyond structural support; they also promote cost efficiency. By reducing the need for frequent repairs and replacements due to corrosion and wear, these materials ultimately save time and resources for construction companies. Their durability contributes to longer life spans for structures, which is a crucial factor in today’s competitive construction market.

Moreover, galvanized reinforced concrete nets are versatile and can be used in a wide variety of applications, including residential, commercial, and industrial buildings. Their reliability makes them a preferred choice for engineers and architects who are focused on creating sustainable and safe constructions.

In conclusion, the establishment of factories producing galvanized reinforced concrete nets marks a significant advancement in the construction industry. With their unique properties, these innovative materials are shaping the future of infrastructure development. As the world continues to evolve, the importance of high-quality, sustainable construction materials will remain paramount, ensuring that galvanized reinforced concrete nets play a crucial role in building the cities of tomorrow.

-

Chain Link Fence-Galvanized Steel Fence Factory|Durable&Versatile

NewsAug.12,2025

-

Chain Link Fence: Durable, Versatile, Reliable | Anping County Puersen

NewsAug.12,2025

-

Chain Link Fence - Anping Puersen | Durable, Versatile Fencing

NewsAug.12,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable, Versatile, Cost-Effective Fencing Solutions

NewsAug.12,2025

-

Chain Link Fence: Durable, Versatile, and Reliable Fencing Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.12,2025

-

Galvanized Steel Fence Factory - Durable & High Quality Fences

NewsAug.12,2025