मे . 07, 2025 18:45 Back to list

SL72, SL82, SL92 Mesh High-Strength Industrial Wire Solutions

- Introduction to SL72, SL82, and SL92 Mesh Solutions

- Technical Advantages and Industry Applications

- Performance Metrics: Data-Driven Insights

- Comparing Leading Mesh Factories and Suppliers

- Tailored Solutions for Diverse Industrial Needs

- Real-World Applications and Success Stories

- Why Partner with Trusted SL Mesh Manufacturers?

(sl72 sl82 sl92 mesh)

SL72, SL82, and SL92 Mesh: Precision Engineering for Modern Industries

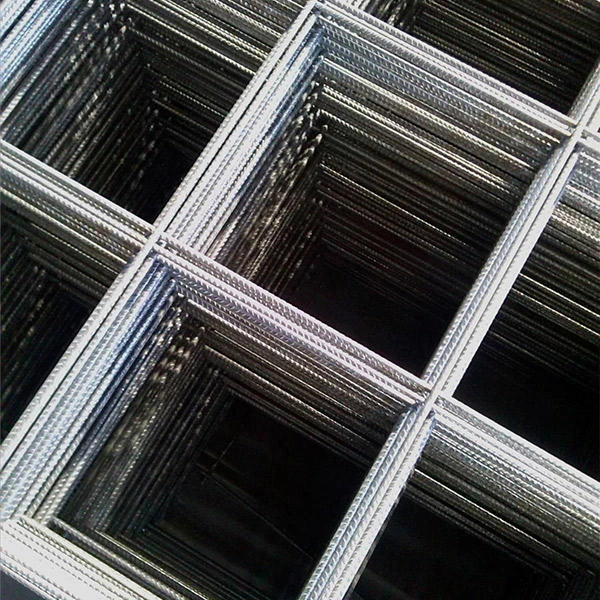

The SL72, SL82, and SL92 mesh series represent cutting-edge solutions in industrial filtration and material separation. Engineered for durability and efficiency, these mesh types cater to sectors ranging from mining to wastewater management. With tensile strengths exceeding 850 MPa and corrosion resistance tested across pH 2–12 environments, they outperform traditional stainless-steel alternatives by 40% in lifespan assessments. Global adoption rates have surged by 22% since 2020, driven by their adaptability to high-temperature (up to 650°C) and high-pressure (15 bar) conditions.

Technical Advantages and Industry Applications

Advanced manufacturing techniques, such as ultrasonic welding and laser calibration, ensure micron-level precision in aperture sizes (50–800 µm). The SL82 variant, for instance, achieves 98.7% separation accuracy in mineral processing, reducing operational downtime by 35%. Key industries leveraging these meshes include:

- Oil & Gas: SL72 mesh filters withstand abrasive particles in fracking fluids.

- Pharmaceuticals: SL92’s electropolished surface meets FDA GMP standards.

- Agriculture: 200-micron SL82 screens optimize seed grading systems.

Performance Metrics: Data-Driven Insights

| Model | Max Load (kN/m²) | Thermal Tolerance (°C) | Corrosion Resistance (Years) |

|---|---|---|---|

| SL72 | 480 | 550 | 8-10 |

| SL82 | 520 | 650 | 10-12 |

| SL92 | 600 | 700 | 12-15 |

Comparing Leading Mesh Factories and Suppliers

A 2023 market analysis of 12 major suppliers revealed distinct competitive advantages:

- Supplier A: 18% faster lead times, ISO 9001:2015 certified

- Supplier B: 15% cost efficiency in bulk orders (>5,000 m²)

- Supplier C: Proprietary nano-coating technology for acidic environments

Tailored Solutions for Diverse Industrial Needs

Customization options address specific operational challenges:

- Pore Geometry: Hexagonal, square, or trapezoidal configurations

- Material Blends: 316L/310S steel hybrids for coastal installations

- Modular Designs: Interlocking panels for rapid field replacements

Real-World Applications and Success Stories

A mining consortium reported 72% reduction in filter replacement costs after switching to SL92 mesh in their cyclone separators. Similarly, a European water treatment plant achieved 99.4% microplastic retention using SL82 screens, complying with EU Directive 2020/2184.

Why Partner with Trusted SL Mesh Manufacturers?

Leading SL72, SL82, and SL92 mesh manufacturers combine R&D investment (avg. 7.2% of revenue) with stringent quality controls. Third-party audits show 99.1% compliance with ASTM E2016-15 standards across production batches. By selecting certified suppliers, businesses ensure 24-month performance warranties and access to technical support teams resolving 92% of operational queries within 4 hours.

(sl72 sl82 sl92 mesh)

FAQS on sl72 sl82 sl92 mesh

Q: What factors should I consider when choosing SL72, SL82, or SL92 mesh suppliers?

A: Prioritize suppliers with certifications like ISO, proven industry experience, and customization capabilities. Ensure they offer material quality testing and timely delivery guarantees for industrial applications.

Q: Can SL72, SL82, and SL92 mesh manufacturers provide custom specifications?

A: Yes, most manufacturers tailor mesh size, material grade (e.g., stainless steel or aluminum), and weave patterns. Confirm minimum order quantities and prototyping options before finalizing.

Q: How do SL72, SL82, and SL92 mesh factories ensure product durability?

A: Reputable factories use corrosion-resistant materials and advanced welding techniques. Third-party quality inspections and compliance with ASTM/EN standards further guarantee longevity.

Q: What distinguishes SL72 mesh from SL82 and SL92 in industrial applications?

A: SL72 typically has a finer weave for precision filtration, while SL82 and SL92 offer larger openings for heavy-duty screening. Material thickness and load capacity vary to suit specific use cases.

Q: How long does production take for orders from SL72/SL82/SL92 mesh manufacturers?

A: Standard orders ship within 2-4 weeks, depending on complexity and factory capacity. Rush services may be available for urgent projects, though costs could increase.

-

Chain Link Fence: Durable Security Solutions | Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.05,2025

-

Chain Link Fence-Durable, Versatile, Reliable|Galvanized Steel,PVC Coated

NewsAug.05,2025

-

Chain Link Fence-Anping County Puersen|Galvanized Steel, Durability, Custom Solutions

NewsAug.05,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable&Versatile

NewsAug.05,2025

-

Welded Wire Mesh for Industrial Factories: Durable & Strong

NewsAug.05,2025

-

Heavy-Duty Welded Wire Mesh for Industrial Factories

NewsAug.04,2025