4-р сар . 28, 2024 10:41 Жагсаалт руу буцах

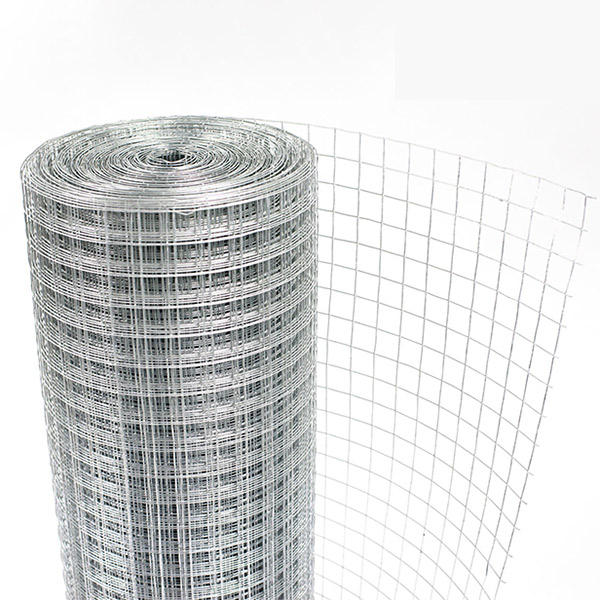

What is welded wire mesh? weld wire mesh

Төмөр тор нэхмэл утаснуудын огтлолцлыг гагнах хагас автомат процессыг ашиглан гагнаж байна. Гагнуурын машинууд нь хэвтээ ба босоо шугаман утаснуудын уулзваруудыг гагнахаар програмчлагдсан байдаг. Эсэргүүцлийн гагнуур, вольфрамын идэвхгүй хий (TIG) гагнуур, плазмын гагнуур, гагнуур зэрэг холболтыг холбохын тулд хэд хэдэн гагнуурын техникийг ашигладаг.

WELDED WIRE MESH

- Гагнуурын торон машин — The process of wire mesh welding begins with feeding wires into a weld mesh machine, which is much like the heddle frames and reeds of wire weaving.

- Утасны дамар — Separate spools of wire are fed through a straightener. Pre-cut wires that match the dimensions of the wire mesh are placed separately from the wires fed from the spools. Since the wires are coming off spools, whether pre-cut or fed from them, they are mechanically straightened to lay flat on the welding surface.

- Механик байршил — The pre-cut wires are laid flat across the wires being fed from the spools. The wires are perpendicular to each other at right angles in mesh welding.

- Гагнуур — Once the wires are positioned, the programmed welding process begins and applies a uniform weld at each cross-section.

- Үйл явцыг дуусгах — The collection of the final wire mesh from the welding process can be in rolls, like wire weaving, or sheets that are trimmed to size and placed in piles of wire mesh panels.

Гагнасан тор нь нэхмэл утсан торноос илүү хүнд, бат бөх, бат бөх бөгөөд зөвхөн гагнуурын процессыг тэсвэрлэх чадвартай зузаан утсаар л ашиглах боломжтой. Утас нь гагнаж байгаа тул илүү хатуу, бат бөх байдаг тул хашаа, тор, бетонон тор зэрэгт тохиромжтой.

-

How PVC Welded Wire Mesh Enhances Industrial Safety Standards

МэдээJul.23,2025

-

Hexagonal Wire Mesh Innovations for Coastal Protection Projects

МэдээJul.23,2025

-

Galvanized Wire Fence Maintenance Tips for Harsh Weather Conditions

МэдээJul.23,2025

-

Galvanized Steel Grating Applications in Industrial Flooring Solutions

МэдээJul.23,2025

-

Energy Absorption Capabilities of Twisted Square Bars in Seismic-Resistant Structures

МэдээJul.23,2025

-

Affordable Chain Link Fence Gate Options for Residential Security

МэдээJul.23,2025