12-р сар . 13, 2024 20:47 Back to list

oem electro galvanized wire mesh

Understanding OEM Electro Galvanized Wire Mesh

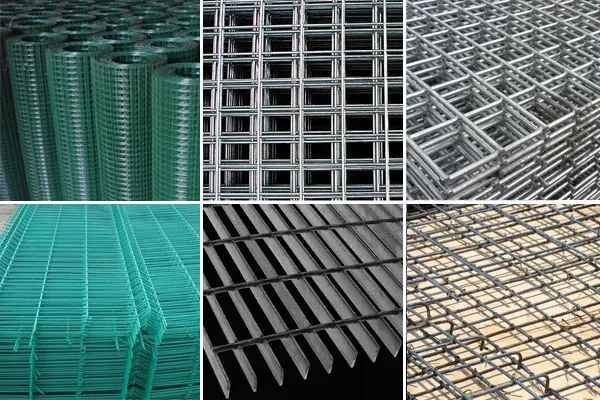

In the world of construction and manufacturing, materials play a pivotal role in determining the longevity, strength, and performance of various products. One such material that has garnered significant attention is OEM electro galvanized wire mesh. This specialized type of wire mesh is not only known for its robustness but also for its versatility across a range of applications.

What is Electro Galvanized Wire Mesh?

Electro galvanized wire mesh is a type of wire mesh that has been coated with a layer of zinc through an electroplating process. This process involves the use of electrical current to facilitate the deposition of zinc onto the steel wire, providing a protective barrier against rust and corrosion. This method of galvanization results in a thinner layer of zinc compared to hot-dip galvanizing, making it suitable for applications where aesthetics and precision are paramount.

The “OEM” in OEM electro galvanized wire mesh refers to “Original Equipment Manufacturer.” It indicates that the wire mesh is produced by a manufacturer that designs and fabricates products based on the specifications provided by another company. This relationship allows for customized solutions tailored to meet specific needs, ensuring high-quality outputs that align with client requirements.

Applications of OEM Electro Galvanized Wire Mesh

The versatility of OEM electro galvanized wire mesh makes it a favored choice in various industries. Here are some common applications

1. Construction Used extensively in building projects, this type of wire mesh serves as reinforcement in concrete structures. It can also be employed as fencing or barriers in construction sites, ensuring safety and security.

2. Agriculture Farmers utilize electro galvanized wire mesh for creating fencing for livestock protection and crop enclosures. The corrosion-resistant quality of the mesh ensures durability in outdoor environments.

3. Manufacturing In industrial settings, electro galvanized wire mesh is used for sorting, filtering, and sieving processes. Its strength and non-corrosive nature make it ideal for equipment that must withstand harsh conditions.

oem electro galvanized wire mesh

4. Furniture OEM electro galvanized wire mesh can be seen in various furniture designs. Whether used in shelving or as decorative screens, the combination of strength and aesthetic appeal creates unique pieces that stand the test of time.

5. Infrastructure Urban planners and engineers often incorporate this wire mesh into drainage systems and retaining walls, ensuring structural integrity and longevity in public works.

Advantages of OEM Electro Galvanized Wire Mesh

- Corrosion Resistance The zinc coating creates a protective layer that prevents rust and extends the lifespan of the wire mesh, making it ideal for outdoor applications.

- Cost-Effective The manufacturing process of electro galvanized wire mesh is generally more economical than other galvanizing methods, making it a viable option for large-scale projects.

- Customizable OEM providers often offer bespoke solutions that can be tailored to specific dimensions and wire gauges, catering to the unique requirements of various industries.

- Aesthetic Appeal With its clean and polished finish, electro galvanized wire mesh can enhance the visual appeal of products, making it suitable for both functional and decorative applications.

Conclusion

OEM electro galvanized wire mesh stands as a testament to innovation in material science, marrying functionality with durability. Its wide array of applications speaks to its versatility across different sectors, from construction to agriculture and beyond. As industries continue to evolve, the demand for reliable, corrosion-resistant materials like OEM electro galvanized wire mesh will undoubtedly persist, paving the way for further advancements and adaptations in the field. Embracing such materials not only enhances product quality but also contributes to a sustainable approach in manufacturing practices. Whether used in large-scale industrial applications or smaller projects, this wire mesh offers an invaluable asset that resonates with both performance and design considerations.

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025