സെപ് . 30, 2024 20:07 Back to list

Stud Bolt ASTM A193 B16 Specifications and Factory Manufacturing Guide

Understanding Stud Bolts ASTM A193 B16 Standards and Factory Practices

In the world of industrial fasteners, stud bolts play an integral role in ensuring the reliability and stability of various mechanical systems. Among the various standards that govern the manufacturing and testing of stud bolts, ASTM A193 B16 is particularly noteworthy. This standard outlines the specifications for stud bolts used in high-temperature or high-pressure applications, making them essential components in industries such as oil and gas, power generation, and chemical processing.

Overview of ASTM A193 B16

ASTM A193 is a specification developed by the American Society for Testing and Materials (ASTM) that focuses on alloy and stainless steel bolting materials for high-temperature or high-pressure service and other special applications. The B16 designation refers specifically to the grade of steel that is capable of withstanding specific strength and temperature requirements. Stud bolts made under this specification are designed to perform reliably under harsh conditions, which is why they are widely adopted in critical applications.

Composition and Properties

The B16 grade is typically made of alloy steel, which may include chromium, molybdenum, and other elements to enhance its corrosion resistance, strength, and toughness. The exact composition can vary based on specific application requirements, but the primary focus is on maintaining high tensile strength and yield strength, particularly under high-temperature environments. The mechanical properties of ASTM A193 B16 bolting include a minimum yield strength of 100,000 psi and a tensile strength that often exceeds 120,000 psi.

Manufacturing Process

Manufacturing stud bolts that conform to ASTM A193 B16 standards requires a meticulous process. It begins with selecting high-quality raw materials, usually in the form of bars or rods made from specified alloy steel. These materials undergo various processes such as heating, forging, and machining to achieve the required geometry and finishes.

Heat treatment plays a crucial role in enhancing the mechanical properties of the stud bolts. Processes such as quenching and tempering are commonly employed to improve hardenability and toughness, ensuring that the finished product will perform adequately in demanding applications.

stud bolt astm a193 b16 factory

Quality Control and Testing

Quality control is paramount in the production of ASTM A193 B16 stud bolts. Manufacturers employ a range of tests to verify the material properties and structural integrity of the bolts. Destructive testing methods, such as tensile tests, are conducted to measure strength and elongation, while non-destructive tests are also employed to identify any internal flaws that could compromise bolt performance.

Additionally, manufacturers often conduct microstructural analysis and hardness testing to ensure consistent quality across products. Compliance with ASTM A193 standards not only enhances safety but also ensures that the bolts will meet the operational demands of critical industrial environments.

Factory Considerations

When sourcing stud bolts from a factory, it is essential to consider various factors. First, ensure that the factory is equipped with the necessary certifications and follows ASTM standards diligently. A reputable manufacturer should be transparent about their quality control processes and willing to provide certification documents that validate the compliance of their products with ASTM A193 B16 specifications.

Moreover, understanding the factory's experience and technical capabilities can provide insights into their ability to handle custom orders or special requirements. The facilities should ideally be equipped with modern machinery and testing equipment that allows for efficient production and rigorous quality assurance.

Conclusion

Stud bolts that meet ASTM A193 B16 standards are vital components in many industrial applications, providing essential strength and reliability. By understanding the specifications, manufacturing practices, and quality assurance measures involved in producing these fasteners, engineers and procurement specialists can make informed decisions when sourcing stud bolts for their projects. Investing in high-quality, compliant products ultimately contributes to the safety and performance of critical engineering systems.

-

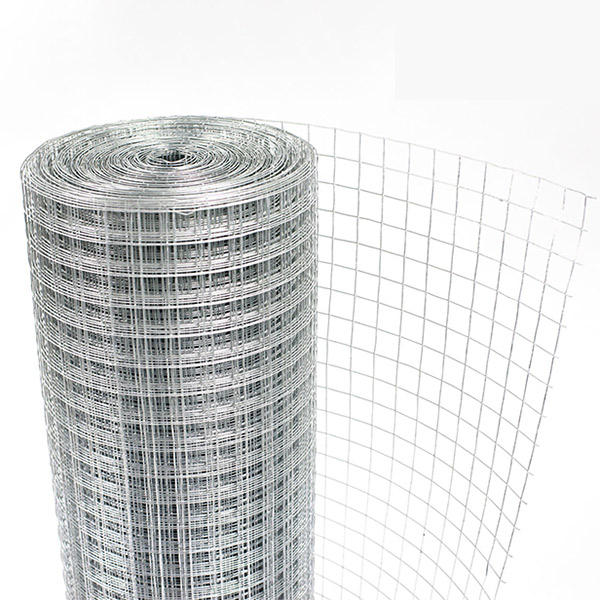

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025