നവം . 09, 2024 14:20 Back to list

Top Manufacturers of 12 Gauge Welded Wire Mesh for Various Applications

Understanding 12% Gauge Welded Wire Mesh A Comprehensive Guide to Manufacturers

Welded wire mesh is a versatile and essential component in various industries, from construction to agriculture. Among the numerous specifications available, the 12% gauge welded wire mesh is particularly noteworthy due to its strength and durability. This article aims to explore the significance of 12% gauge welded wire mesh, the characteristics that distinguish it, and what to consider when selecting manufacturers for this product.

What is 12% Gauge Welded Wire Mesh?

First, it is important to understand what “gauge” refers to in wire mesh terminology. The gauge refers to the diameter of the wire used in the mesh, with lower numbers indicating thicker wires. A 12-gauge wire mesh typically has a diameter of approximately 2.64 mm (0.104 inches), making it stronger than many of its thinner counterparts. Welded wire mesh, as the name suggests, consists of wires that have been electrically welded together at the intersections, providing superior integrity and stability.

The “12%” in 12% gauge welded wire mesh may refer to its specific formulation or an added characteristic that enhances its durability or resistance to corrosion. While actual specifications may vary, the emphasis is on creating a product that is both reliable and capable of withstanding mechanical stresses.

Applications of 12% Gauge Welded Wire Mesh

The applications of 12% gauge welded wire mesh are vast and varied. Here are some of the primary uses

1. Construction In construction, this type of wire mesh is primarily used as reinforcement in concrete structures. It helps to distribute loads evenly, enhancing the overall strength of buildings, bridges, and slabs. 2. Fencing Due to its robust nature, 12% gauge welded wire mesh is used in agricultural and industrial fencing. Whether securing livestock, enclosing properties, or safeguarding industrial sites, this mesh offers durability and protection.

3. HVAC and Screening In the heating, ventilation, and air conditioning (HVAC) industry, welded wire mesh can be utilized for screens and filters, which can effectively control airflow and debris.

5. Road and Highway Construction The mesh is often incorporated in road construction projects as part of the foundation and reinforcement systems.

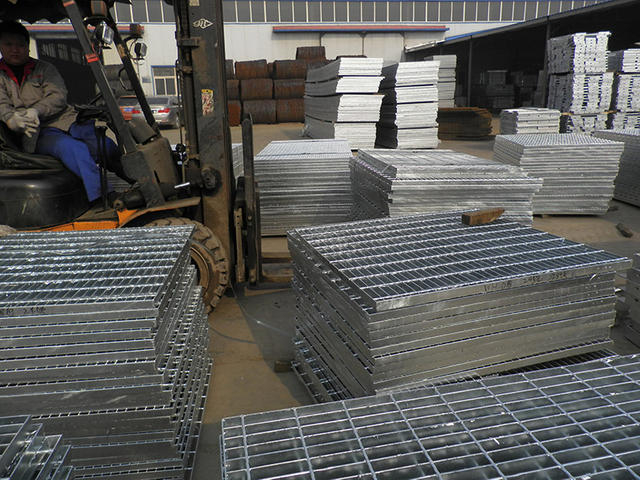

12 gauge welded wire mesh manufacturers

Choosing the Right Manufacturer

When selecting a manufacturer for 12% gauge welded wire mesh, several factors should be taken into consideration

1. Quality Control Ensure the manufacturer adheres to stringent quality control processes. High-quality mesh will undergo inspections and certifications to validate its strength and durability.

2. Material Sourcing The material used in the wire mesh is critical. Opt for manufacturers that use high-grade steel and corrosion-resistant coatings, ensuring longevity in diverse environments.

3. Customization Options Many projects may require specific dimensions or designs. Look for manufacturers that offer customizable options to suit your specific needs.

4. Industry Experience Consider manufacturers with a proven track record in the industry. Experience often translates into better craftsmanship and customer service.

5. Pricing While it is essential to find a manufacturer that fits your budget, be wary of prices that seem too good to be true. Quality often comes at a reasonable cost, so balance budget constraints with the need for reliability and durability.

6. Customer Support Reliable customer service can be a vital feature, especially when addressing concerns or modifications during the purchasing process.

Conclusion

In conclusion, 12% gauge welded wire mesh is a robust and versatile product that plays a significant role in various industries. Its strength, durability, and ability to withstand environmental pressures make it an ideal choice for construction, fencing, manufacturing, and more. By carefully selecting the right manufacturer, customers can ensure that they receive a high-quality product suited to their specific applications. Whether you are involved in agriculture, construction, or industrial manufacturing, investing in quality welded wire mesh is essential for achieving long-lasting and reliable results.

-

Heavy-Duty Welded Wire Mesh for Industrial Factories

NewsAug.04,2025

-

Chain Link Fence - Anping County Puersen | Durable, Versatile, Reliable

NewsAug.03,2025

-

Chain Link Fence: Durable, Versatile, and Reliable Fencing Solution|Galvanized Steel Fence Manufacturers

NewsAug.03,2025

-

Chain Link Fence-Galvanized Steel Fence Factory|Durable, Versatile, Cost-Effective

NewsAug.03,2025

-

Heavy-Duty Welded Wire Mesh for Industrial Factories

NewsAug.03,2025

-

Galvanized Steel Fence-Anping Puersen|Durable,Flexible

NewsAug.02,2025