Мар . 05, 2025 02:36 Back to list

welded wire mesh for industry factories

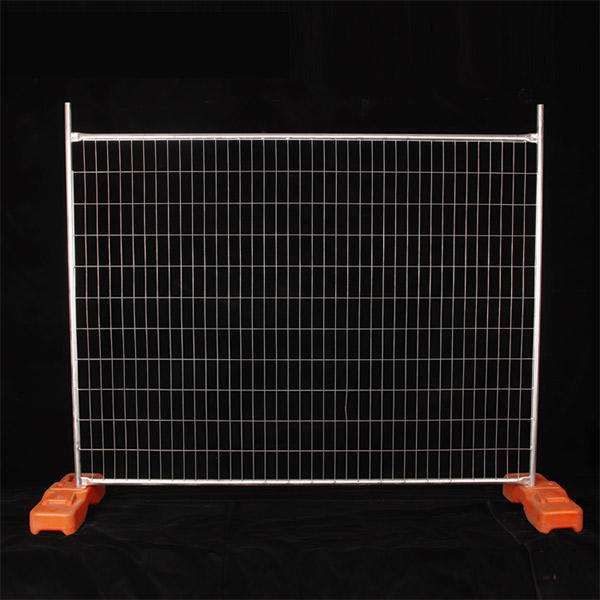

Galvanized welded wire mesh is a staple in industries ranging from agriculture to construction, offering unparalleled durability and versatility. Choosing the right ISO-certified factory for this product can be a game-changer for businesses requiring reliable and quality materials. Whether you are involved in constructing fences, cages, or other operational frameworks, understanding the role of galvanized welded wire mesh and the importance of sourcing from ISO-certified factories can enhance your project's success.

For businesses considering a supplier, understanding their process and certification standards is essential. An ISO-certified galvanized welded wire mesh factory demonstrates transparency in its operations and commits to continuous improvement through regular audits and updates in compliance standards. This commitment involves utilizing advanced technology for production and ensuring that personnel are skilled and trained according to international benchmarks. Trustworthiness is also reinforced through client testimonials and project case studies that highlight successful implementations and the role of quality materials in achieving desired outcomes. Factories with a strong track record not only showcase their expertise but also instill confidence in potential customers who rely on industry experts to support their infrastructural needs. Expertise in this domain rests upon knowledgeable personnel who understand diverse applications and can advise on suitable products based on specific environmental or operational challenges. ISO-certified factories typically offer such expertise, with professionals ready to assist clients from the planning stages through to execution. In conclusion, when seeking galvanized welded wire mesh suppliers, prioritizing ISO-certified factories is imperative for quality assurance, expert guidance, and sustainable business practices. This strategic decision not only enhances product performance but also aligns with the growing need for responsible manufacturing, thereby ensuring businesses achieve their construction or operational objectives efficiently and reliably.

For businesses considering a supplier, understanding their process and certification standards is essential. An ISO-certified galvanized welded wire mesh factory demonstrates transparency in its operations and commits to continuous improvement through regular audits and updates in compliance standards. This commitment involves utilizing advanced technology for production and ensuring that personnel are skilled and trained according to international benchmarks. Trustworthiness is also reinforced through client testimonials and project case studies that highlight successful implementations and the role of quality materials in achieving desired outcomes. Factories with a strong track record not only showcase their expertise but also instill confidence in potential customers who rely on industry experts to support their infrastructural needs. Expertise in this domain rests upon knowledgeable personnel who understand diverse applications and can advise on suitable products based on specific environmental or operational challenges. ISO-certified factories typically offer such expertise, with professionals ready to assist clients from the planning stages through to execution. In conclusion, when seeking galvanized welded wire mesh suppliers, prioritizing ISO-certified factories is imperative for quality assurance, expert guidance, and sustainable business practices. This strategic decision not only enhances product performance but also aligns with the growing need for responsible manufacturing, thereby ensuring businesses achieve their construction or operational objectives efficiently and reliably.

Latest news

-

Heavy-Duty Welded Wire Mesh for Industrial Factories

NewsAug.04,2025

-

Chain Link Fence - Anping County Puersen | Durable, Versatile, Reliable

NewsAug.03,2025

-

Chain Link Fence: Durable, Versatile, and Reliable Fencing Solution|Galvanized Steel Fence Manufacturers

NewsAug.03,2025

-

Chain Link Fence-Galvanized Steel Fence Factory|Durable, Versatile, Cost-Effective

NewsAug.03,2025

-

Heavy-Duty Welded Wire Mesh for Industrial Factories

NewsAug.03,2025

-

Galvanized Steel Fence-Anping Puersen|Durable,Flexible

NewsAug.02,2025