Dec . 04, 2024 22:19 Back to list

Choosing the Right Sizes of Welded Wire Mesh for Concrete Production

Understanding Welded Wire Mesh Sizes for Concrete A Guide for Manufacturers

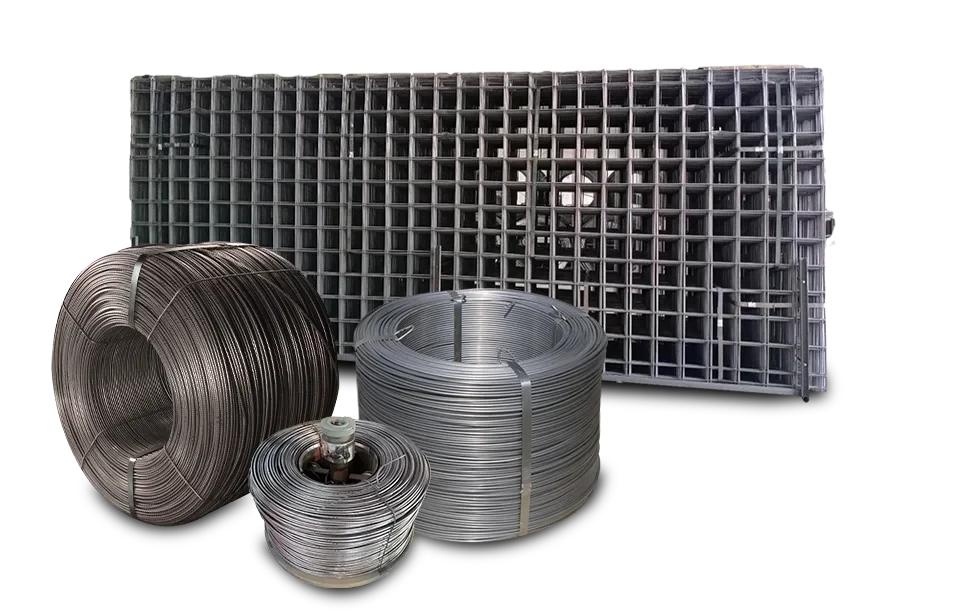

Welded wire mesh has become an essential component in the construction industry, particularly in the reinforcement of concrete structures. By incorporating welded wire mesh into concrete applications, manufacturers can ensure enhanced strength, durability, and integrity of the final product. Understanding the various sizes and specifications of welded wire mesh is crucial for manufacturers looking to optimize their offerings and meet industry standards.

What is Welded Wire Mesh?

Welded wire mesh consists of intersecting wires that are welded together at specific intervals, creating a grid-like pattern. This mesh can be produced in various sizes, shapes, and materials, commonly steel, to cater to different construction needs. The primary function of welded wire mesh is to distribute weight and stress evenly across concrete structures, minimizing the risk of cracks and structural failures.

Common Sizes of Welded Wire Mesh

The sizes of welded wire mesh can vary significantly based on the application and the specific structural requirements. However, there are standard configurations that are widely used in the industry.

1. Wire Diameter The wire diameter refers to the thickness of the wires that form the mesh. It usually ranges from 1.2 mm (0.047 inches) to 4.0 mm (0.157 inches). Thicker wires provide greater strength and are ideal for heavy-duty applications, while thinner wires are suitable for lighter concrete applications.

2. Mesh Opening Size The mesh opening size is the space between the wires. This can vary, with common sizes including 50 mm x 50 mm (2 in x 2 in), 75 mm x 75 mm (3 in x 3 in), and 100 mm x 100 mm (4 in x 4 in). The choice of opening size often depends on the type of concrete being used and the specific load requirements.

3. Sheet Dimensions Welded wire mesh sheets typically come in standard dimensions, such as 2.4 m x 6 m (8 ft x 20 ft), 1.2 m x 6 m (4 ft x 20 ft), or 3.0 m x 6 m (10 ft x 20 ft). Custom sizes can also be manufactured to fit specific designs and construction plans.

Choosing the Right Welded Wire Mesh Size

Selecting the appropriate welded wire mesh size involves several considerations

welded wire mesh sizes for concrete manufacturers

- Project Specifications Different construction projects have varying requirements based on load-bearing capacities, soil conditions, and building codes. Reviewing the specifications provided by engineers and architects is critical when choosing the right size of welded wire mesh.

- Concrete Type The type of concrete used also influences the selection of mesh size. For instance, fiberglass-reinforced concrete might require a different mesh specification compared to traditional Portland cement concrete.

- Environmental Conditions In areas with extreme weather patterns or seismic activity, additional reinforcement may be necessary. Choosing a larger wire diameter or smaller mesh opening may enhance the structural integrity of the concrete.

Benefits of Using Welded Wire Mesh

Manufacturers who incorporate welded wire mesh into their concrete formulations can enjoy numerous benefits

1. Increased Load-Bearing Capacity Properly sized welded wire mesh distributes loads more evenly, increasing the overall strength of the concrete structure.

2. Crack Prevention By minimizing the chance of cracks forming in concrete, manufacturers can improve the longevity and aesthetic appeal of their products.

3. Cost-Effectiveness Using welded wire mesh can optimize material use, reducing the overall costs related to additional reinforcement materials and labor.

4. Efficient Installation Welded wire mesh is easy to install and can save time on-site, contributing to more efficient construction processes.

Conclusion

As the construction industry continues to evolve, understanding the various sizes and specifications of welded wire mesh is paramount for manufacturers. By choosing the right mesh size and utilizing it effectively, construction professionals can enhance the quality and durability of concrete structures, ensuring safety and longevity. Knowledge of welded wire mesh sizes is not only beneficial for manufacturers but also for engineers and architects aiming to create robust and sustainable buildings.

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.23,2025

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen|Durable Security Solution&Cost-Effective Fencing

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsJul.21,2025

-

Galvanized Steel Chain Link Fences-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable Corrosion-Resistant Fencing&Cost-Effective Security Solutions

NewsJul.21,2025

-

Diamond Steel Grating - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable Industrial Solutions&Customized Steel Grating

NewsJul.21,2025