Feb . 14, 2025 16:39 Back to list

diamond steel grating factories

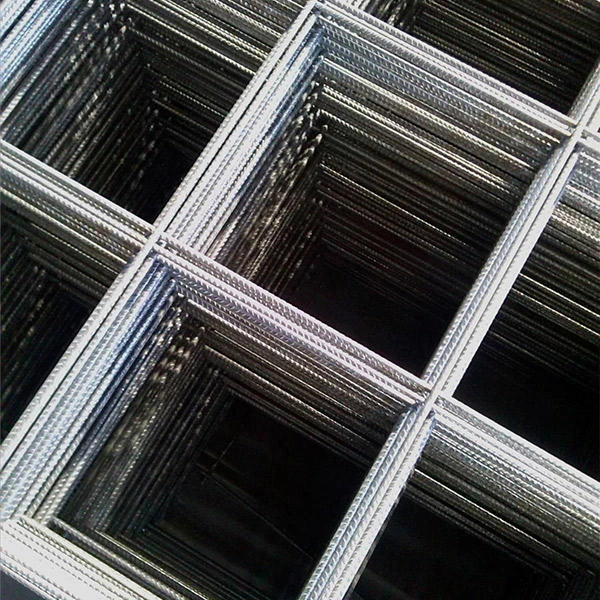

In the construction industry, selecting the right materials is crucial for the stability and longevity of a project. Among these materials, deformed steel rebar stands as a cornerstone, utilized abundantly in structures for its impressive tensile strength and practical features. As we delve into the intricacies of wholesale deformed steel rebar, we aim to enhance your understanding of its application, benefits, and essential purchasing considerations which underline its selection as an indispensable product in the world of construction.

Sharing experiences from previous projects adds an invaluable layer of credibility and insight. For instance, in a large urban infrastructure project in Southeast Asia, the choice of using top-grade deformed steel rebar resulted in improved durability of the structures, even in harsh environmental conditions. These real-world examples reinforce the significance of selecting high-quality rebar tailored to the unique demands of each project. Further reflecting on industry case studies, a study conducted on the long-term performance of reinforced concrete structures revealed that using high-quality deformed steel rebar minimized maintenance costs significantly. The enhanced bonding capabilities of these rebars helped in resisting cracks and deformations, contributing to the extended lifespan of the structures, which provided cost savings and reduced environmental impact by lowering material turnover. For construction companies and contractors considering wholesale purchases, understanding market trends and pricing dynamics is pivotal. The cost of steel rebar is influenced by factors like raw material prices, energy costs, and shipping logistics. Monitoring these fluctuations is crucial in securing favorable terms and maintaining profitability. Bulk purchasing often opens opportunities for negotiated discounts and supply chain efficiencies, further enhancing the economic value. In conclusion, the choice of deformed steel rebar in construction is not merely a matter of compliance but a strategic decision impacting the long-term success of building endeavors. By focusing on the product's specifications, supplier reliability, and integrating learned experiences from previous applications, stakeholders can optimize their use of this essential construction material. Through comprehensive expertise, authority, and a commitment to trustworthiness, the potential for developing durable infrastructures that stand the test of time is significantly increased.

Sharing experiences from previous projects adds an invaluable layer of credibility and insight. For instance, in a large urban infrastructure project in Southeast Asia, the choice of using top-grade deformed steel rebar resulted in improved durability of the structures, even in harsh environmental conditions. These real-world examples reinforce the significance of selecting high-quality rebar tailored to the unique demands of each project. Further reflecting on industry case studies, a study conducted on the long-term performance of reinforced concrete structures revealed that using high-quality deformed steel rebar minimized maintenance costs significantly. The enhanced bonding capabilities of these rebars helped in resisting cracks and deformations, contributing to the extended lifespan of the structures, which provided cost savings and reduced environmental impact by lowering material turnover. For construction companies and contractors considering wholesale purchases, understanding market trends and pricing dynamics is pivotal. The cost of steel rebar is influenced by factors like raw material prices, energy costs, and shipping logistics. Monitoring these fluctuations is crucial in securing favorable terms and maintaining profitability. Bulk purchasing often opens opportunities for negotiated discounts and supply chain efficiencies, further enhancing the economic value. In conclusion, the choice of deformed steel rebar in construction is not merely a matter of compliance but a strategic decision impacting the long-term success of building endeavors. By focusing on the product's specifications, supplier reliability, and integrating learned experiences from previous applications, stakeholders can optimize their use of this essential construction material. Through comprehensive expertise, authority, and a commitment to trustworthiness, the potential for developing durable infrastructures that stand the test of time is significantly increased.

Latest news

-

Chain Link Fence: Durable, Versatile, Reliable | Anping County Puersen

NewsAug.12,2025

-

Chain Link Fence - Anping Puersen | Durable, Versatile Fencing

NewsAug.12,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable, Versatile, Cost-Effective Fencing Solutions

NewsAug.12,2025

-

Chain Link Fence: Durable, Versatile, and Reliable Fencing Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.12,2025

-

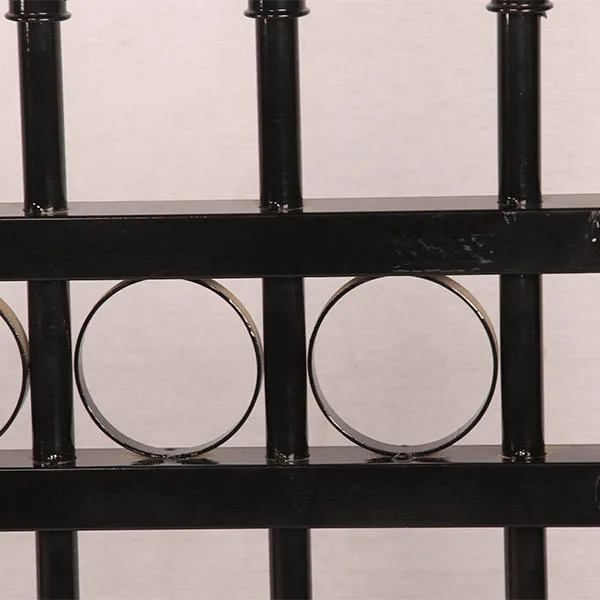

Galvanized Steel Fence Factory - Durable & High Quality Fences

NewsAug.12,2025

-

Chain Link Fence-Anping | Durable&Versatile Fencing

NewsAug.11,2025