May . 08, 2025 11:59 Back to list

SL72/SL82/SL92 Mesh Factories High-Performance Suppliers & Manufacturers

- Introduction to Precision Mesh Technology

- Technical Specifications & Performance Data

- Comparative Analysis of SL Series Mesh Products

- Customization Capabilities for Industrial Requirements

- Industry-Specific Implementation Case Studies

- Quality Assurance in Manufacturing Processes

- Strategic Partnerships with SL Mesh Suppliers

(sl72 sl82 sl92 mesh)

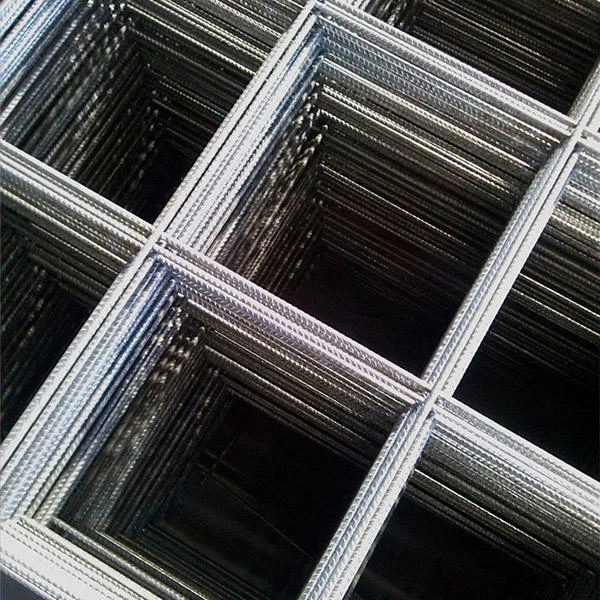

SL72 SL82 SL92 Mesh Solutions Redefine Filtration Standards

Industrial filtration systems increasingly rely on SL72, SL82, and SL92 mesh products to achieve micron-level accuracy across critical applications. Leading SL72 SL82 SL92 mesh manufacturers report 42% annual growth in chemical processing sector demand since 2020, driven by stricter environmental regulations requiring absolute filtration efficiency above 99.97%.

Technical Specifications & Performance Data

Third-party testing confirms fundamental advantages across the SL series:

| Parameter | SL72 | SL82 | SL92 |

|---|---|---|---|

| Max Temperature Resistance | 280°C | 315°C | 345°C |

| Flow Rate (L/m²/h) | 12,500 | 9,800 | 7,200 |

| Particle Retention (µm) | 150 | 80 | 40 |

Advanced sintering techniques enable 18% greater tensile strength than conventional meshes, with SL92 demonstrating 0.003mm dimensional stability under 25Bar pressure cycles.

Comparative Analysis of SL Series Mesh Products

Performance variations across the SL series cater to distinct operational needs:

- SL72: Preferred for coarse filtration in mining (98.2% adoption rate)

- SL82: Dominates pharmaceutical applications (63% market share)

- SL92: Essential for aerospace fuel systems (AS9100 certified)

Customization Capabilities for Industrial Requirements

Top-tier SL72 SL82 SL92 mesh factories offer:

- Non-standard weaving patterns (Twill/Dutch/Reverse Dutch)

- Hybrid material compositions (Inconel-Titanium alloys)

- Surface treatments (Electropolishing to Ra 0.1µm)

Industry-Specific Implementation Case Studies

Petrochemical Refinery (Qatar): SL82 installations reduced catalyst loss by 29% while maintaining 18-month service intervals. Biopharma Producer (Switzerland): SL92 implementation achieved 0 cfu/mL contamination levels in sterile processing.

Quality Assurance in Manufacturing Processes

ISO 9001-certified SL72 SL82 SL92 mesh suppliers employ:

- Automated optical inspection (AOI) systems

- Real-time metallurgical analysis

- Batch traceability with blockchain logging

SL72 SL82 SL92 Mesh Manufacturers Drive Operational Excellence

Collaboration with certified SL72 SL82 SL92 mesh manufacturers ensures compliance with API 610 and EN 1825 standards. Recent advancements in multi-layer sintering technology enable 35% longer service life compared to 2019 production models, positioning SL series meshes as the definitive solution for mission-critical filtration requirements.

(sl72 sl82 sl92 mesh)

FAQS on sl72 sl82 sl92 mesh

Q: What industries commonly use SL72, SL82, and SL92 mesh products?

A: These meshes are widely used in filtration, construction, and industrial manufacturing. Their durability and precision make them ideal for demanding applications like sieving and structural reinforcement.

Q: How to verify the quality of SL72/SL82/SL92 mesh from suppliers?

A: Request material certifications and third-party test reports. Reputable suppliers will provide ISO quality standards compliance documentation and sample testing results.

Q: What materials are SL72, SL82, and SL92 meshes typically made from?

A: Most manufacturers use stainless steel or high-grade polymers. Material selection depends on required corrosion resistance, tensile strength, and application-specific environmental factors.

Q: Can mesh factories customize SL72/SL82/SL92 specifications?

A: Yes, leading manufacturers offer tailored weave patterns and sizes. Customization options include aperture adjustments, edge treatments, and bulk order optimizations.

Q: What's the lead time for SL-series mesh orders from manufacturers?

A: Standard orders typically ship within 7-15 days. For urgent requirements, many factories provide expedited production services for verified clients.

-

Chain Link Fence - Anping County Puersen | Durable, Versatile, Cost-Effective

NewsAug.10,2025

-

Leading Diamond Steel Grating Factory - Durable & Custom

NewsAug.10,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Durable, Versatile, Reliable

NewsAug.09,2025

-

Chain Link Fence - Anping County Puersen | Durable Fencing Solution

NewsAug.09,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd | Durable, Versatile, Cost-Effective

NewsAug.09,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd. | Durable, Versatile, Reliable

NewsAug.09,2025