Feb . 18, 2025 09:35 Back to list

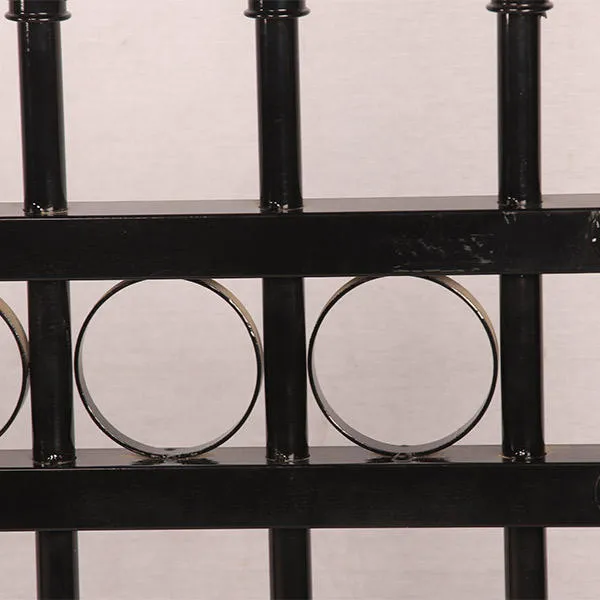

welded wire mesh for industry factories

OEM Black Annealed Wire A Superior Choice for Industrial Applications

Beyond construction, black annealed wire serves indispensably in the recycling industry. Its flexibility and strength make it a perfect component in the processing and compacting of recyclable materials. The wire's ability to withstand significant pressure without breaking contributes to efficient and safe operation, leading to enhanced productivity and reduced downtime in recycling operations. Moreover, in artistic applications, the wire’s pliability allows sculptors and artists to create intricate designs effortlessly. Its ability to hold shape after molding makes it a preferred medium for artwork, facilitating creativity without the risk of damage or detangling. Despite its many advantages, selecting a trustworthy supplier is paramount to ensure consistently high-grade materials. High-quality OEM black annealed wire should come with certifications assuring compliance with industry standards. Reliable suppliers provide transparency in their manufacturing processes, reinforcing their credibility through quality assurance and regular audits. Finally, regular feedback from end-users remains critical. Engaging with industry forums and attending trade expos can provide insights into newer applications and technological advancements in black annealed wire. Networking with peers and experts helps stay abreast of trends, ensuring that applications of the wire are both innovative and efficient. In conclusion, OEM black annealed wire stands out as a premier choice in many sectors due to its strength, flexibility, and economic value. Selecting quality wire, understanding its capabilities, and sourcing it from credible manufacturers ensures that businesses can rely on its performance for their diverse needs. Whether for industrial, recycling, or artistic purposes, black annealed wire represents a cornerstone material that continues to adapt and evolve with modern applications, underscoring its indispensability in today’s manufacturing landscape.

Beyond construction, black annealed wire serves indispensably in the recycling industry. Its flexibility and strength make it a perfect component in the processing and compacting of recyclable materials. The wire's ability to withstand significant pressure without breaking contributes to efficient and safe operation, leading to enhanced productivity and reduced downtime in recycling operations. Moreover, in artistic applications, the wire’s pliability allows sculptors and artists to create intricate designs effortlessly. Its ability to hold shape after molding makes it a preferred medium for artwork, facilitating creativity without the risk of damage or detangling. Despite its many advantages, selecting a trustworthy supplier is paramount to ensure consistently high-grade materials. High-quality OEM black annealed wire should come with certifications assuring compliance with industry standards. Reliable suppliers provide transparency in their manufacturing processes, reinforcing their credibility through quality assurance and regular audits. Finally, regular feedback from end-users remains critical. Engaging with industry forums and attending trade expos can provide insights into newer applications and technological advancements in black annealed wire. Networking with peers and experts helps stay abreast of trends, ensuring that applications of the wire are both innovative and efficient. In conclusion, OEM black annealed wire stands out as a premier choice in many sectors due to its strength, flexibility, and economic value. Selecting quality wire, understanding its capabilities, and sourcing it from credible manufacturers ensures that businesses can rely on its performance for their diverse needs. Whether for industrial, recycling, or artistic purposes, black annealed wire represents a cornerstone material that continues to adapt and evolve with modern applications, underscoring its indispensability in today’s manufacturing landscape.

Next:

Latest news

-

Chain Link Fence - Anping County Puersen | Durability&Customization

NewsAug.11,2025

-

High-Quality Welded Wire Mesh for Industry Factory Direct

NewsAug.11,2025

-

Galvanized Steel Fence Factory | Durable, Versatile, Reliable

NewsAug.11,2025

-

Chain Link Fence - Anping County Puersen | Durability, Flexibility, Cost-Effective

NewsAug.11,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable&Versatile

NewsAug.11,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd | Durable Security, Versatile Application

NewsAug.10,2025