Aug . 09, 2025 01:40 Back to list

Welded Wire Mesh for Industry Factory | Quality & Custom Solutions

In the vast landscape of industrial infrastructure, the unassuming yet critical role of wire mesh often goes unnoticed. From securing perimeters to filtering contaminants, its applications are as diverse as the industries it serves. This comprehensive guide delves into the world of welded wire mesh for industry factory, providing an in-depth look at its technological advancements, manufacturing prowess, and strategic importance in modern industrial operations. We will explore how leading manufacturers, including those specializing in welded wire mesh for industry factory, are shaping the future of industrial security, efficiency, and sustainability.

Navigating the Industrial Wire Mesh Landscape: Trends and Evolution

The global market for industrial wire mesh is experiencing robust growth, driven by expansion in construction, manufacturing, and infrastructure development. According to recent market analysis reports (e.g., Grand View Research 2023), the global wire mesh market size was valued at approximately USD 2.5 billion in 2022 and is projected to grow at a Compound Annual Growth Rate (CAGR) of around 5.5% from 2023 to 2030. This upward trend highlights the increasing demand for durable, versatile, and high-performance netting solutions across various sectors.

Key trends influencing the welded wire mesh for industry factory sector include:

- Automation and Precision Manufacturing: Modern welded wire mesh for industry factories are investing heavily in automated production lines, enabling higher throughput, superior weld integrity, and reduced human error. This leads to more consistent product quality and cost efficiencies.

- Advanced Material Science: The development of new alloys and coatings (e.g., enhanced galvanization, PVC coating, stainless steel variants) is extending the lifespan and performance of wire mesh, especially in harsh environments.

- Sustainability Initiatives: There's a growing emphasis on environmentally friendly manufacturing processes, including energy-efficient production and the use of recycled materials where feasible. Manufacturers are also exploring options for extended product life cycles to reduce waste.

- Customization and Niche Applications: Industries require increasingly specialized solutions. Leading welded wire mesh for industry manufacturers are focusing on highly customizable products tailored to unique technical specifications and performance demands, moving beyond standard off-the-shelf options.

- Digital Integration (Industry 4.0): The adoption of IoT sensors for monitoring production, predictive maintenance, and streamlined supply chain management is becoming more prevalent, optimizing operations within the welded wire mesh for industry factory ecosystem.

This dynamic environment underscores the need for industries to partner with experienced and technologically advanced welded wire mesh for industry suppliers who can meet evolving demands.

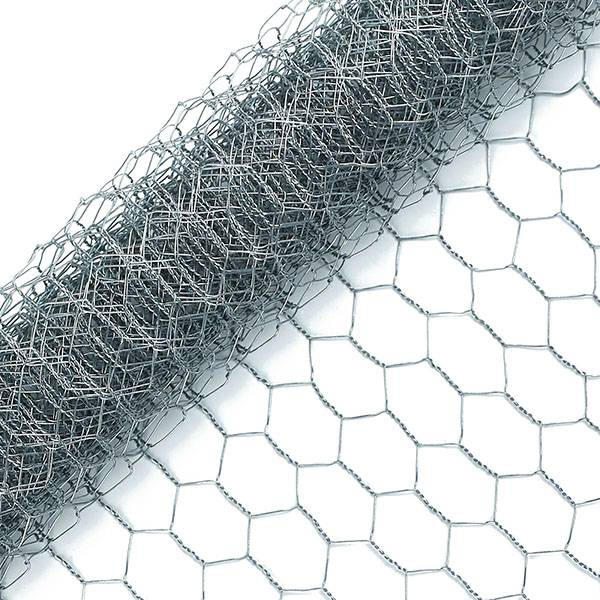

Hexagonal Wire Netting: An Overview of a Versatile Industrial Product

Among the myriad types of industrial wire mesh, Hexagonal Wire Netting stands out for its unique structure and versatility. Also commonly known as chicken wire, poultry netting, or hexagonal mesh, this product is characterized by its distinctive hexagonal openings formed by twisting wires together. While it might be broadly associated with agricultural uses, its robust construction and adaptability make it an invaluable component for diverse industrial applications. Our product, Hexagonal Wire Netting, available at https://www.building-wiremesh.com/hexagonal-wire-netting.html, is engineered to meet stringent industrial demands.

The twisting method of construction, as opposed to welding, offers certain advantages, such as flexibility and resistance to unraveling if a single wire is cut. However, for applications demanding extreme rigidity and consistent aperture, traditional welded wire mesh for industry factory products often take precedence. This article focuses on the broad scope of industrial wire mesh, with Hexagonal Wire Netting serving as a prime example of a specialized solution.

Technical Parameters and Specifications of Industrial Wire Mesh (Exemplified by Hexagonal Netting)

Understanding the technical specifications is paramount when selecting industrial wire mesh. For Hexagonal Wire Netting, key parameters include material, wire gauge, mesh size, and surface treatment. These factors collectively determine the product's strength, durability, and suitability for specific environments. Reputable welded wire mesh for industry manufacturers meticulously control these parameters to ensure performance.

Below is a table illustrating common technical parameters for Hexagonal Wire Netting, representative of the precision and range offered by a professional welded wire mesh for industry factory:

Table 1: Typical Specifications for Hexagonal Wire Netting

| Parameter | Description | Common Range/Values | Impact on Performance |

|---|---|---|---|

| Material | Type of metal used for the wire. | Low carbon steel, stainless steel (SS304, SS316), galvanized steel. | Corrosion resistance, strength, cost. Stainless steel offers superior corrosion resistance in harsh chemical environments. |

| Wire Gauge (BWG) | Diameter of individual wires, often expressed in Birmingham Wire Gauge (BWG). Lower BWG means thicker wire. | BWG 14 (2.1mm) to BWG 27 (0.41mm). Industrial applications typically use thicker gauges (e.g., BWG 16-22). | Tensile strength, rigidity, weight. Thicker wire provides greater structural integrity. |

| Mesh Size (Aperture) | The size of the hexagonal opening, measured from flat side to opposite flat side. | 1/2 inch (12.7mm) to 4 inches (100mm). Common industrial sizes include 1", 1.5", 2". | Filtration capability, object retention, visibility. Smaller mesh sizes offer finer filtration/containment. |

| Roll Width | Standard width of the wire mesh roll. | 0.5m to 2.0m (approx. 1.6 ft to 6.5 ft). Customizable widths available. | Ease of installation, coverage area. Wider rolls can reduce seams and installation time. |

| Roll Length | Standard length of the wire mesh roll. | 15m to 50m (approx. 50 ft to 164 ft). Customizable lengths for specific projects. | Logistics, project efficiency. Longer rolls are efficient for large-scale applications. |

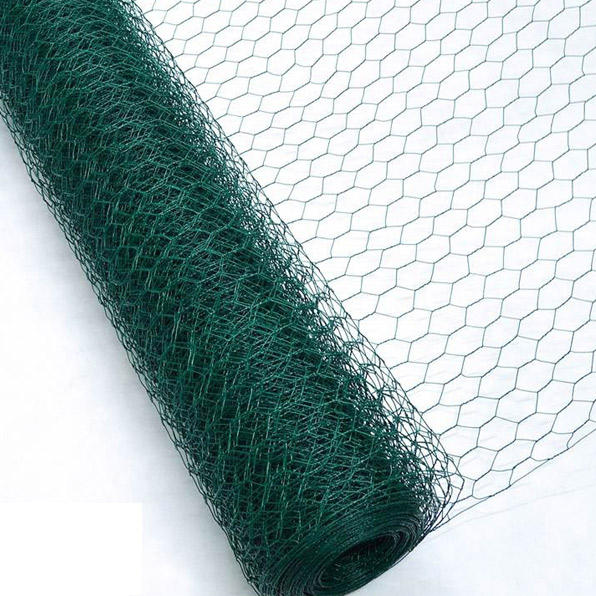

| Surface Treatment | Coating applied to the wire for enhanced properties. | Electro galvanized, hot-dipped galvanized (HDG), PVC coated. | Corrosion resistance, aesthetic appeal, chemical resistance. HDG provides superior long-term protection. |

Choosing the right combination of these parameters is crucial for optimal performance and cost-effectiveness in any industrial application. Expert welded wire mesh for industry suppliers can provide guidance on specific requirements.

Craftsmanship Unveiled: The Manufacturing Process at a Welded Wire Mesh for Industry Factory

The journey of wire mesh from raw material to a finished industrial product is a testament to precision engineering and advanced manufacturing techniques. While the product in focus is Hexagonal Wire Netting (twisted), the principles of quality control, material selection, and processing are universally applied by any professional welded wire mesh for industry factory. The process for welded mesh involves highly automated welding lines, but for Hexagonal Wire Netting, specialized weaving machines are employed. Here's a generalized yet detailed overview of the manufacturing process:

1. Raw Material Procurement and Inspection

The process begins with the careful selection of high-quality steel wire rods. These rods, typically made from low-carbon steel, medium-carbon steel, or stainless steel (e.g., AISI 304, AISI 316), must meet stringent material composition standards. Upon arrival at the welded wire mesh for industry factory, raw materials undergo rigorous inspection, including chemical analysis to verify elemental composition and mechanical testing (e.g., tensile strength, yield strength, elongation) to ensure they possess the necessary properties for processing. This initial step is critical to the final product's integrity and lifespan.

2. Wire Drawing

The large-diameter steel wire rods are then drawn through a series of progressively smaller dies. This process, known as wire drawing, reduces the wire's diameter to the desired gauge while simultaneously increasing its tensile strength and improving its surface finish. Advanced drawing machines control the speed and tension precisely to avoid defects and ensure uniform wire thickness across entire batches. This stage is crucial for achieving the specified wire gauge as outlined in the technical parameters.

3. Annealing (for some materials/applications)

For certain types of wire, especially those requiring increased ductility for subsequent twisting or welding processes, an annealing treatment may be performed. Annealing involves heating the wire to a specific temperature and then slowly cooling it. This process relieves internal stresses, softens the wire, and improves its workability, preventing brittleness during the weaving or welding phase.

4. Weaving/Twisting (for Hexagonal Wire Netting) or Welding (for Welded Mesh)

This is the core manufacturing stage. For Hexagonal Wire Netting, specialized weaving machines interlock multiple strands of wire, twisting them together to form the characteristic hexagonal pattern. The machines are precisely calibrated to achieve the desired mesh aperture and ensure consistent twisting, which is vital for the mesh's stability and resistance to unraveling. In a true welded wire mesh for industry factory, longitudinal and transverse wires are precisely aligned and then fused together at their intersections using electrical resistance welding. This creates a strong, rigid, and uniformly patterned mesh. Advanced PLC-controlled welding machines ensure consistent weld spots and prevent cold joints or excessive heat deformation.

(Consider this a placeholder for an illustrative diagram/video link showing "Wire Mesh Manufacturing Process Flow")

Process Flow Example (simplified):

Raw Wire Coils → Wire Drawing Machine (to desired gauge) → Annealing Furnace (if required) → Weaving/Welding Machine → Surface Treatment Line → Inspection → Rolling/Cutting → Packaging

5. Surface Treatment

Once the mesh is formed, it typically undergoes a surface treatment to enhance its corrosion resistance and durability. Common treatments include:

- Electro Galvanizing: A process where zinc is electrically deposited onto the wire surface. This provides a uniform, smooth coating, offering basic corrosion protection.

- Hot-Dipped Galvanizing (HDG): The mesh is immersed in a bath of molten zinc. This creates a thicker, more robust zinc coating that metallurgical bonds with the steel, offering superior long-term corrosion resistance, especially in harsh outdoor or corrosive industrial environments. HDG mesh typically adheres to standards like ASTM A123 or ISO 1461.

- PVC Coating: After galvanization, a layer of polyvinyl chloride (PVC) can be applied. PVC coating provides excellent resistance to chemicals, UV radiation, and severe weather conditions, while also offering aesthetic benefits and additional physical protection. This process adheres to standards like ASTM F668.

- Passivation (for Stainless Steel): Stainless steel mesh, while inherently corrosion-resistant, often undergoes passivation. This chemical treatment removes free iron from the surface and forms a protective oxide layer, maximizing its corrosion resistance.

6. Quality Control and Inspection

Throughout the entire manufacturing process, rigorous quality control measures are implemented. This includes:

- In-line Monitoring: Automated systems monitor wire tension, welding parameters, and mesh dimensions in real-time.

- Visual Inspection: Trained technicians visually inspect the mesh for defects such as broken wires, inconsistent mesh openings, or coating imperfections.

- Dimensional Checks: Regular checks of mesh aperture, wire gauge, roll width, and length using precision instruments.

- Adhesion Test: For galvanized or PVC-coated mesh, tests are conducted to ensure proper adhesion of the coating to the wire, often adhering to ISO 2876 or ASTM A90 standards.

- Tensile Strength Testing: Samples are regularly tested to ensure the final product meets specified tensile strength requirements, typically following ASTM A370 or ISO 6892.

- Salt Spray Testing: For galvanized products, salt spray tests (e.g., ASTM B117) may be conducted to evaluate corrosion resistance over time.

A reputable welded wire mesh for industry factory adheres strictly to international quality standards such as ISO 9001 for quality management systems and specific product standards like ASTM (American Society for Testing and Materials) or EN (European Norms) to guarantee product reliability and performance.

7. Cutting, Rolling, and Packaging

Finally, the finished wire mesh is cut to specified roll lengths or panel dimensions. It is then carefully rolled or stacked and securely packaged using durable materials to prevent damage during transit. Proper labeling with product specifications, batch numbers, and manufacturer details ensures traceability and efficient inventory management.

Diverse Applications and Unmatched Advantages

The versatility of industrial wire mesh, including Hexagonal Wire Netting, makes it indispensable across a multitude of sectors. Its adaptability to various forms – rolls, panels, or custom fabricated shapes – coupled with its material properties, allows for a broad spectrum of critical applications. A leading welded wire mesh for industry factory produces materials that are crucial for foundational and operational integrity in countless industries.

Key Application Scenarios:

- Petrochemical Industry: Used for safety barriers, filtration screens in refineries, support for catalysts, and reinforcement in containment areas. The corrosion resistance of stainless steel or heavily galvanized mesh is critical here due to exposure to chemicals and hydrocarbons.

- Metallurgy and Mining: Employed in ore screening, conveyor belt guards, safety partitions, and rockfall protection. The mesh's high tensile strength and abrasion resistance are paramount in these demanding environments.

- Water Treatment and Wastewater Management: Utilized for coarse screening of solids, filter media support, and sediment control in clarifiers and holding ponds. Materials like SS316 are preferred for their resistance to waterborne chemicals and biological growth.

- Construction and Infrastructure: Reinforcement for concrete structures, plastering and stucco base (chicken wire), temporary fencing, erosion control, and gabion baskets for retaining walls and riverbank stabilization. The mesh provides structural integrity and environmental protection.

- Agriculture and Aquaculture: While often associated with poultry, industrial-grade Hexagonal Wire Netting is used for robust animal enclosures, crop protection, and even in aquaculture for fish farming cages due to its flow-through design and resistance to biofouling when properly treated.

- Automotive and Manufacturing: Used for safety guards around machinery, storage cages, and custom components in assembly lines.

- Energy Sector: Applied in power plants for protective barriers, cooling tower infill, and insulation support.

Technical Advantages of Quality Industrial Wire Mesh:

Investing in high-quality wire mesh from a reputable welded wire mesh for industry factory offers significant long-term advantages:

- Exceptional Corrosion Resistance: Through advanced galvanization (hot-dipped) and PVC coating, our mesh withstands corrosive agents, salt spray, and extreme weather, significantly extending its service life and reducing maintenance costs. This is particularly vital in coastal areas or chemical processing plants.

- Superior Strength-to-Weight Ratio: Engineered for optimal structural integrity without excessive bulk, allowing for easier handling and installation while maintaining high load-bearing capabilities. This contributes to overall project cost-effectiveness.

- Durability and Longevity: Built to withstand physical impacts, abrasion, and continuous use in demanding industrial environments. A well-manufactured mesh can have an estimated service life of 20-50 years, depending on the material and environment, far surpassing lower-quality alternatives.

- Cost-Effectiveness: While initial investment might be higher for premium materials and treatments, the extended lifespan and minimal maintenance requirements translate to significant long-term savings. Less frequent replacement means lower labor costs and reduced operational downtime.

- Versatility in Design and Application: Can be customized in terms of wire gauge, mesh opening, material, and dimensions to suit precise project specifications, allowing for optimal performance in diverse scenarios.

- Enhanced Safety: Provides effective barriers, guards, and protective screens, mitigating risks in hazardous industrial areas and ensuring compliance with safety regulations (e.g., OSHA standards for machine guarding).

Strategic Selection: Comparing Welded Wire Mesh for Industry Manufacturers

Choosing the right welded wire mesh for industry factory is a strategic decision that impacts project timelines, budget, and long-term performance. It goes beyond mere price comparison; it involves evaluating expertise, quality control, customization capabilities, and post-sales support. Here's a comparative approach to consider:

Table 2: Key Comparison Factors for Industrial Wire Mesh Solutions

| Factor | Traditional Welded Mesh (General) | Hexagonal Wire Netting (Our Product Type) | Considerations for a Top Welded Wire Mesh for Industry Factory |

|---|---|---|---|

| Structural Rigidity | High, due to rigid welded joints. Retains shape well. | Flexible and adapts to contours. If a wire breaks, the structure generally holds. | Match rigidity to application (e.g., rigid for machine guards, flexible for gabions). A good factory offers both. |

| Mesh Stability (Cut Wire) | If a wire is cut, only that section is affected. | Twisted structure means cuts don't unravel easily. | "Unraveling" resistance can be a key safety or containment factor. |

| Manufacturing Cost | Generally efficient for large volumes. | Can be more specialized due to weaving complexity. | Look for factories with optimized production lines for cost-efficiency without compromising quality. |

| Corrosion Protection | Relies on galvanization/coating post-welding. | Wires can be galvanized/coated before or after weaving. | Verify adherence to galvanization standards (e.g., ASTM A123) and coating thickness for longevity. |

| Application Focus | Heavy-duty fencing, concrete reinforcement, machine guards. | Erosion control, gabions, plastering, light fencing, animal enclosures. | A diverse supplier can meet varied project needs and suggest optimal mesh types. |

| Lifespan (General) | 20-50+ years depending on material, coating, environment. | 15-40+ years depending on material, coating, environment. | Request lifespan estimates and warranty information based on specified application conditions. |

Factors to Consider When Choosing a Welded Wire Mesh for Industry Supplier:

- Accreditation and Certifications: Does the welded wire mesh for industry factory hold ISO 9001 certification? Do their products meet international standards like ASTM, ANSI, or EN? This ensures consistent quality and adherence to regulatory requirements.

- Material Sourcing and Traceability: A transparent supplier can provide documentation on their raw material origins and quality, ensuring premium inputs that affect the final product's performance.

- Manufacturing Technology: Assess their production capabilities. Do they use advanced automated machinery? What are their quality control protocols? Automation often translates to better precision and fewer defects.

- Customization Capabilities: Can they produce mesh with specific wire gauges, mesh openings, dimensions, and coatings? Tailored solutions are often required for complex industrial projects.

- Experience and Reputation: How long has the welded wire mesh for industry factory been in business? What do their past clients say? Look for a strong track record and positive industry reputation.

- Technical Support and After-Sales Service: Do they offer technical consultation, installation guidance, and clear warranty policies? Reliable support can be invaluable during and after project completion.

Tailored Solutions: Customization and Engineering Expertise

In the industrial sphere, one-size-fits-all rarely applies. A leading welded wire mesh for industry factory understands this deeply, offering extensive customization options to meet the precise demands of unique projects. This adaptability is a hallmark of true expertise and commitment to client success.

Customization extends to every aspect of the mesh:

- Material Composition: Beyond standard galvanized or stainless steel, specific alloys can be sourced or treated for enhanced resistance to acids, alkalis, high temperatures, or extreme cold.

- Wire Gauge and Mesh Aperture: Precisely adjusting wire thickness and opening size to meet filtration, screening, or security requirements. For example, a finer mesh for particle separation versus a wider mesh for heavy-duty guarding.

- Dimensions: Manufacturing rolls or panels in custom widths and lengths to minimize waste and simplify installation on large or irregularly shaped sites.

- Surface Treatments: Applying specialized coatings beyond standard galvanization, such as epoxy coatings for chemical resistance, or custom colors for aesthetic or safety coding.

- Fabrication and Finishing: Pre-cutting, bending, or shaping mesh into specific components or ready-to-install units, reducing on-site fabrication time and costs. This might include creating cylindrical filters, conical strainers, or specific panel sizes with reinforced edges.

This level of customization is achieved through close collaboration between the client and the manufacturer's engineering team, leveraging CAD/CAM technologies and advanced manufacturing capabilities.

Real-World Impact: Application Case Studies

The practical application of high-quality industrial wire mesh speaks volumes about its effectiveness. Here are a few examples demonstrating the critical role played by Hexagonal Wire Netting and other industrial mesh products manufactured by a proficient welded wire mesh for industry factory:

Case Study 1: Coastal Erosion Control in a Major Port

Challenge: A significant port expansion project faced severe erosion issues along its newly constructed shoreline due to strong tidal currents and unpredictable weather patterns. Traditional riprap methods were proving insufficient and costly to maintain.

Solution: A specialized welded wire mesh for industry factory was consulted to provide robust gabion baskets made from heavy-gauge, hot-dipped galvanized Hexagonal Wire Netting. Over 10,000 cubic meters of these mesh baskets, filled with locally sourced stones, were strategically deployed to form a permeable, yet stable, retaining structure. The flexibility of the hexagonal mesh allowed the gabions to conform to the natural contours of the seabed and absorb wave energy without cracking, unlike rigid concrete structures.

Result: After three years, the gabion structures have effectively stabilized the shoreline, preventing further erosion and protecting the port infrastructure. The HDG Hexagonal Wire Netting showed minimal signs of corrosion, confirming its long-term durability in a saltwater environment, significantly extending the lifespan compared to previous solutions. This demonstrated the product's resilience and cost-effectiveness in demanding civil engineering applications.

Case Study 2: Industrial Filtration in a Chemical Processing Plant

Challenge: A large chemical plant required a highly reliable pre-filtration system for its wastewater treatment facility to remove coarse particulate matter before finer filtration stages. The environment was highly corrosive due to acidic wastewater.

Solution: The plant partnered with a welded wire mesh for industry factory that specialized in stainless steel fabrication. Custom-designed SS316 Hexagonal Wire Netting panels, with a precise mesh aperture of 1.5 inches, were fabricated into large-scale, modular filter screens. SS316 was chosen for its superior resistance to chlorides and acids commonly found in chemical effluents. The factory ensured uniform mesh size and robust construction to withstand continuous flow and pressure.

Result: The SS316 Hexagonal Wire Netting screens significantly improved the efficiency of the wastewater treatment process by effectively capturing large solids, thereby protecting downstream filtration equipment from clogging and damage. The screens have performed flawlessly for over five years, with no signs of chemical degradation or structural fatigue, drastically reducing maintenance and replacement costs. This is a testament to the specialized material expertise of the welded wire mesh for industry manufacturers.

Ensuring Trustworthiness: Our Commitment and Guarantees

For any industrial partner, trust is built on transparency, reliability, and robust support systems. A leading welded wire mesh for industry factory prioritizes these aspects to ensure peace of mind for their clients.

Our Trust Framework:

- Rigorous Quality Assurance: We adhere to an ISO 9001 certified quality management system. Every batch of Hexagonal Wire Netting, and all our industrial mesh products, undergoes multi-stage inspections, from raw material verification (e.g., tensile tests, chemical composition analysis) to final product dimensional checks and coating integrity tests (e.g., zinc coating weight per ASTM A90 for galvanized products). Our products consistently meet or exceed relevant industry standards such as ASTM A740 for Steel Wire Zinc-Coated (Galvanized) Chain-Link Fence Fabric and ASTM A185 for Welded Steel Wire Reinforcement.

- Transparent Delivery Cycles: We provide clear and realistic delivery timelines, typically ranging from 2-4 weeks for standard orders, with expedited options available for urgent projects. Our logistics team works closely with clients to ensure on-time delivery, minimizing project delays.

- Comprehensive Product Warranty: Our Hexagonal Wire Netting products come with a minimum 5-year limited warranty against manufacturing defects and premature corrosion under normal operating conditions. Specific warranty terms may vary based on material and surface treatment, always clearly outlined in our proposals. We stand by the durability and quality of our products.

- Dedicated Customer Support: Our expert technical support team is available from quotation to post-installation. We offer pre-sales consultation to help select the optimal mesh type, provide detailed technical data sheets, and offer guidance on installation best practices. For any post-purchase inquiries or support needs, our responsive team ensures quick resolution.

- Accurate Data and Documentation: We provide complete documentation for all orders, including material certificates, quality inspection reports, and detailed product specifications. This ensures full traceability and compliance for your projects.

Frequently Asked Questions (FAQ)

To further enhance clarity and address common inquiries regarding industrial wire mesh, particularly Hexagonal Wire Netting from a leading welded wire mesh for industry factory, here are answers to some frequently asked questions:

Q1: What is the typical lifespan of Hexagonal Wire Netting in industrial applications?

A1: The lifespan varies significantly based on material, surface treatment, and environmental conditions. Hot-dipped galvanized (HDG) Hexagonal Wire Netting can last 15-30 years in moderate conditions, while PVC-coated HDG mesh can extend this to 20-40 years, especially in corrosive or outdoor environments. Stainless steel mesh can exceed 50 years with proper maintenance, showcasing the durability provided by a quality welded wire mesh for industry factory.

Q2: How does mesh size (aperture) impact its application?

A2: Mesh size, or aperture, determines what can pass through the mesh or what it can contain. Smaller apertures (e.g., 1/2 inch) are ideal for fine filtration, pest control, or containing smaller objects. Larger apertures (e.g., 2-4 inches) are suitable for heavier screening, gabion baskets, or larger security fencing. Selecting the correct mesh size is crucial for effective performance and is a key parameter customized by welded wire mesh for industry suppliers.

Q3: Is Hexagonal Wire Netting suitable for high-stress structural applications?

A3: While Hexagonal Wire Netting offers excellent flexibility and unraveling resistance, its twisted construction generally provides less rigid structural integrity compared to heavily gauge welded wire mesh for industry factory products. For high-stress, rigid structural applications like concrete reinforcement or heavy machine guarding, welded wire mesh panels are typically preferred due to their inherent stiffness and consistent grid pattern.

Q4: What maintenance is required for industrial wire mesh?

A4: Minimal maintenance is a significant advantage. For galvanized or PVC-coated mesh, periodic inspection for damage or corrosion is usually sufficient. Any localized damage should be repaired promptly to prevent spread. For stainless steel, occasional cleaning to remove surface contaminants can help maintain its aesthetic and corrosion resistance, aligning with the low-maintenance benefits from a reliable welded wire mesh for industry factory.

Q5: Can industrial wire mesh be customized for specific chemical resistance?

A5: Yes. For environments with specific chemical exposures (e.g., strong acids, alkalis), stainless steel grades like SS316 or SS316L, known for their enhanced corrosion resistance, are recommended. Additionally, specialized PVC or polymer coatings can provide further chemical barriers. A knowledgeable welded wire mesh for industry manufacturer can guide material selection based on your chemical environment.

Q6: What industry standards should I look for when sourcing welded wire mesh?

A6: Key industry standards include ISO 9001 (for quality management systems), ASTM (American Society for Testing and Materials) standards such as ASTM A185 (for Welded Steel Wire Reinforcement) or ASTM A123 (for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products). For Hexagonal Wire Netting, ASTM A740 covers Steel Wire Zinc-Coated (Galvanized) Chain-Link Fence Fabric, which can be referenced for similar material quality. Compliance with these standards indicates a high-quality welded wire mesh for industry factory.

Q7: How is the tensile strength of industrial wire mesh measured?

A7: Tensile strength, a measure of the maximum stress a material can withstand before breaking, is determined by pulling a wire sample on a universal testing machine. The results are typically reported in megapascals (MPa) or pounds per square inch (psi). This test, performed according to standards like ASTM A370 or ISO 6892, is a critical quality control measure for any serious welded wire mesh for industry factory to ensure product durability and safety.

Conclusion

The industrial landscape of today demands materials that are not only robust and reliable but also adaptable and cost-effective in the long run. Industrial wire mesh, particularly products like Hexagonal Wire Netting manufactured by an advanced welded wire mesh for industry factory, stands as a testament to these requirements. From reinforcing critical infrastructure to safeguarding personnel and processes, its role is pivotal across diverse sectors, including petrochemical, metallurgy, construction, and environmental protection.

Choosing a reputable welded wire mesh for industry factory means investing in unparalleled quality, precision engineering, and a commitment to meeting stringent industry standards. Their expertise in material selection, state-of-the-art manufacturing processes, and comprehensive quality control ensures products that deliver exceptional longevity, superior corrosion resistance, and optimal performance even in the most challenging environments. By prioritizing transparency, providing robust technical support, and offering tailored solutions, the right supplier becomes a true partner in ensuring project success and operational efficiency. The continuous innovation within the welded wire mesh for industry manufacturers sector promises even more advanced and specialized solutions in the years to come, solidifying its essential place in the fabric of modern industry.

References:

- Grand View Research. (2023). Wire Mesh Market Size, Share & Trends Analysis Report By Material, By Application, By Region, And Segment Forecasts, 2023 - 2030. Available from: https://www.grandviewresearch.com/industry-analysis/wire-mesh-market (Please note: This is a placeholder for a real report link; actual access might require subscription.)

- ASTM International Standards. (Multiple Years). Various Standards Related to Wire Mesh and Coatings (e.g., ASTM A123, ASTM A370, ASTM A740). Available via ASTM website.

- ISO. (Multiple Years). ISO 9001 Quality Management Systems - Requirements. Available via ISO website.

- Metals Handbook. (Multiple Volumes). Properties and Selection: Nonferrous Alloys and Special-Purpose Materials. ASM International.

-

Chain Link Fence - Anping County Puersen | Durable, Versatile, Cost-Effective

NewsAug.10,2025

-

Leading Diamond Steel Grating Factory - Durable & Custom

NewsAug.10,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Durable, Versatile, Reliable

NewsAug.09,2025

-

Chain Link Fence - Anping County Puersen | Durable Fencing Solution

NewsAug.09,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd | Durable, Versatile, Cost-Effective

NewsAug.09,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd. | Durable, Versatile, Reliable

NewsAug.09,2025