Jūl . 17, 2025 11:40 Atpakaļ uz sarakstu

Specialized Wire Panel Welded Wire Mesh Fencing Systems

In the fields of infrastructure development, agricultural engineering, and architectural security, hog wire fence panels and Melns metināts stiepļu žoga sieta panelis stand as advanced solutions within the framework of specialized fencing technology. These systems embody a combination of structural robustness and functional flexibility, addressing unique challenges across various industries. This scholarly exploration delves into their mechanical characteristics, application methodologies, and technical attributes, aiming to offer a comprehensive understanding for researchers, engineers, and industry professionals.

Mechanical Design and Material Properties of Hog Wire Fence Panels

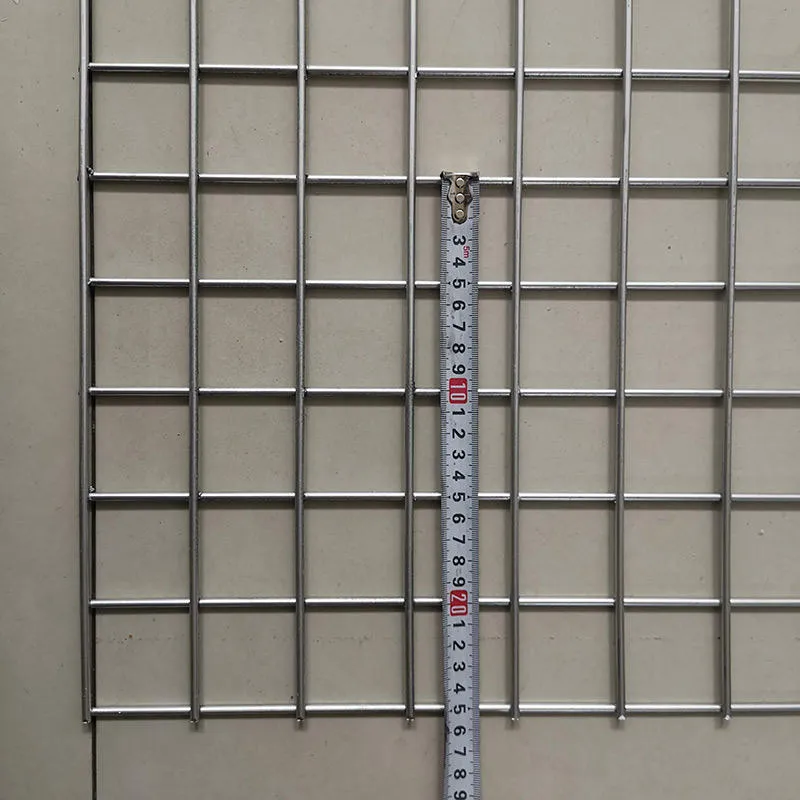

Hog wire fence panels are engineered with a focus on load-bearing capability and environmental endurance. Constructed from high-tensile steel wires, their welded mesh structure—featuring rectangular openings exhibits notable resistance to mechanical stress. The galvanized coating provides corrosion protection in agricultural settings, where exposure to moisture, organic elements, and sunlight is common. The staggered weld pattern ensures uniform force distribution, minimizing stress concentrations and enhancing long-term structural stability. These panels are designed for containing large livestock, offering a durable barrier that balances containment with visibility.

Aesthetic and Functional Synergy in Black Welded Wire Fence Mesh Panel

The Melns metināts stiepļu žoga sieta panelis exemplifies the integration of technical performance and visual appeal. Its electro-welded construction features a uniform mesh configuration, providing a balance between transparency and security. The powder-coat finish offers dual advantages: resistance to environmental factors and a low-maintenance surface that retains its appearance over time. With high tensile strength, this panel type is suitable for applications requiring both protective barriers and architectural harmony, such as urban landscapes, commercial perimeters, and industrial enclosures. The sleek black finish complements modern designs while delivering reliable security.

Installation Mechanics and Environmental Considerations for Wire Panel Welded Wire Mesh Systems

Proper deployment of specialized fencing systems requires attention to geotechnical and climatic conditions. For hog wire fence panels, stable foundation preparation and appropriate post spacing are essential to ensure structural integrity. In corrosive environments, additional protective measures can enhance longevity. Conversely, Melns metināts stiepļu žoga sieta panelis installation demands precise tensioning and the use of compatible fasteners to maintain stability, particularly in challenging climates. Thermal and environmental factors must be considered to prevent structural distortion and ensure long-term performance of stiepļu panelis metināts stiepļu tīkls solutions.

Comparative Performance Analysis of Hog Wire Fence Panels and Black Welded Wire Fence Mesh Panel

A technical comparison of these systems highlights their application-specific optimizations. Hog wire fence panels are designed for agricultural environments, prioritizing durability and livestock containment, while Melns metināts stiepļu žoga sieta panelis excels in urban and commercial settings, combining security with aesthetic integration. Both systems adhere to rigorous manufacturing standards to ensure quality and reliability, with considerations for maintenance and lifecycle costs. Their adaptability to diverse operational conditions makes them valuable across multiple industries, showcasing the versatility of stiepļu panelis metināts stiepļu tīkls technology.

Hog Wire Fence Panels FAQs

How does mesh design impact the performance of hog wire fence panels?

The rectangular mesh structure of hog wire fence panels is engineered to distribute forces effectively, supporting livestock containment while allowing environmental elements to pass through. This design enhances both functional durability and practical usability in agricultural environments.

What environmental factors should be considered for the longevity of Black Welded Wire Fence Mesh Panel?

For Melns metināts stiepļu žoga sieta panelis, exposure to moisture, sunlight, and chemical substances can affect performance. Protective coatings and proper installation techniques are critical to maintaining corrosion resistance and structural integrity in various climatic conditions.

How do wire panel welded wire mesh systems balance security and aesthetics?

Solutions like Melns metināts stiepļu žoga sieta panelis combine robust security features with sleek designs, making them suitable for applications where visual appeal is as important as functional protection, such as residential and commercial properties. The uniform mesh structure of stiepļu panelis metināts stiepļu tīkls ensures both permeability and strength.

What are the key maintenance practices for hog wire fence panels in agricultural use?

Regular inspections and protective treatments are essential for hog wire fence panels to maintain their effectiveness. Addressing signs of wear, such as loose wires or coating damage, promptly ensures long-term reliability in containing livestock and resisting environmental stressors.

How does material selection influence the durability of wire panel welded wire mesh systems?

The choice of high-tensile steel and protective coatings in systems like hog wire fence panels and Melns metināts stiepļu žoga sieta panelis directly impacts their resistance to mechanical stress and environmental factors. Quality materials ensure lasting performance, making these panels reliable investments for various applications.

This analysis demonstrates that hog wire fence panels and Melns metināts stiepļu žoga sieta panelis are specialized solutions within stiepļu panelis metināts stiepļu tīkls technology, each optimized for distinct operational contexts. The former excels in agricultural environments, providing robust livestock containment, while the latter offers a blend of security and aesthetic appeal for urban and commercial settings. Their mechanical strength, environmental adaptability, and adherence to professional standards establish them as essential components in modern infrastructure development.

This scholarly article examines hog wire fence panels and Melns metināts stiepļu žoga sieta panelis, two prominent stiepļu panelis metināts stiepļu tīkls systems. It explores their mechanical properties, installation considerations, and comparative advantages, highlighting their technical excellence in agricultural and architectural applications. By emphasizing design principles and functional adaptability, the paper underscores their roles in delivering reliable, durable solutions that meet the diverse needs of modern industries, showcasing the importance of specialized fencing technology in contemporary engineering.

-

Weld Wire Mesh Applications and Variations

JaunumiJul.17,2025

-

Versatility of Black Annealed Wire

JaunumiJul.17,2025

-

Specialized Wire Panel Welded Wire Mesh Fencing Systems

JaunumiJul.17,2025

-

Multifaceted Utility of Galvanized Metal Wires

JaunumiJul.17,2025

-

Direct Deal Barbed Wire Optimizing Barbed Wire Systems

JaunumiJul.17,2025

-

Cold Drawn Steel Products Key Features and Applications

JaunumiJul.17,2025