Dec . 17, 2024 20:04 Back to list

Cost Analysis of Industrial Steel Welded Wire Mesh Manufacturing

The Prices of Professional Factory Steel Welded Wire Mesh

Steel welded wire mesh is an essential component in various industries, providing structural support and reinforcement in construction and manufacturing processes. It serves a multitude of applications, including fencing, concrete reinforcement, animal enclosures, and many more. As demand continues to grow, understanding the factors that influence the prices of professional factory steel welded wire mesh becomes crucial for buyers and sellers alike.

Overview of Steel Welded Wire Mesh

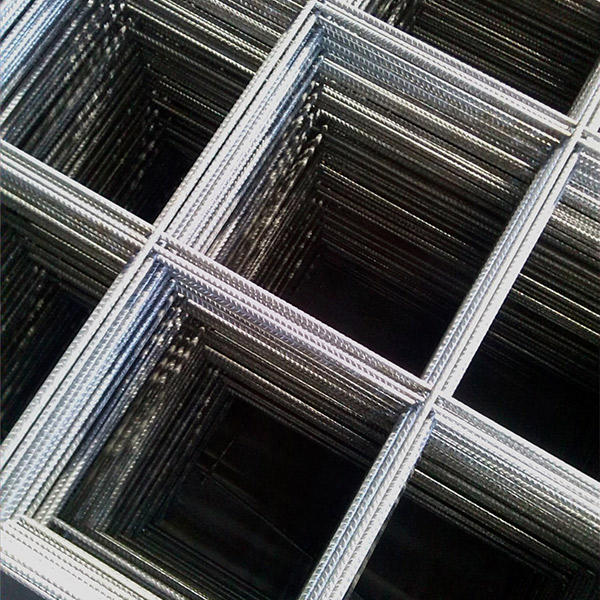

Steel welded wire mesh is made from high-quality steel wire that is welded together at intersections, creating a robust grid-like structure. Its durability and strength make it an ideal choice for many projects. Depending on the gauge of the wire and the size of the openings, the mesh can be customized to meet specific needs. The two primary types of steel used in welded wire mesh are carbon steel and stainless steel, with each providing different characteristics in terms of corrosion resistance and strength.

Factors Affecting Prices

1. Material Costs The price of steel is the most significant factor affecting the cost of welded wire mesh. Global fluctuations in the price of raw steel, influenced by supply and demand, geopolitical events, and economic conditions, can lead to varying costs for wire mesh. Buyers should stay informed about market trends to anticipate changes in pricing.

2. Production Techniques The methods employed in manufacturing welded wire mesh also impact the final cost. Factories that utilize advanced machinery and automated processes can produce mesh at a lower cost due to increased efficiency. Conversely, older, more manual techniques may result in higher labor costs and, subsequently, higher prices for the finished product.

3. Dimensions and Specifications The size and specifications of the wire mesh directly correlate with pricing. Larger rolls or sheets of mesh, specialized gauges, and custom spacing between wires usually command higher prices than standard sizes. Buyers often face trade-offs between customization and cost-efficiency.

prices of professional factory steel welded wire mesh

4. Surface Treatment Steel welded wire mesh can undergo various surface treatments to enhance its durability and longevity. Galvanization, for instance, involves coating the steel with a protective layer to prevent rust and corrosion. While this treatment increases the upfront cost, it can lead to significant long-term savings by extending the life of the product.

5. Market Demand Seasonal changes and regional construction booms can influence the demand for welded wire mesh. In times of increased construction activity, the demand surges, leading to a potential increase in prices. Conversely, slow periods may result in more competitive pricing as manufacturers seek to clear their inventory.

6. Supplier Location The geographic location of the supplier plays a role in pricing. Transportation costs can vary significantly depending on the distance from the factory to the buyer. Additionally, suppliers situated in regions with higher local steel prices may charge more for their products. Buyers should consider sourcing from multiple locations to find the best deal.

Market Trends and Future Outlook

As of late 2023, the steel market continues to exhibit volatility, largely due to global economic uncertainties and policy changes. With sustainability becoming a priority, there is a growing trend towards the use of recycled steel in the production of welded wire mesh. This shift not only supports environmental initiatives but may also affect pricing as recycled materials can lead to cost reductions in the long run.

Innovation in manufacturing techniques and materials is also on the rise, enabling producers to offer a wider range of products and potentially reducing costs. As technology advances, buyers can expect to see enhanced quality and durability at competitive prices.

Conclusion

The prices of professional factory steel welded wire mesh are influenced by a multitude of factors ranging from raw material costs to market demand and production techniques. Understanding these variables can help customers make informed purchasing decisions and navigate the complexities of the market. As the industry evolves, staying abreast of trends and innovations will be essential for those involved in the procurement and use of welded wire mesh products. Ultimately, with careful planning and research, businesses can secure high-quality steel welded wire mesh that meets their needs without breaking the budget.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025