Spa . 13, 2024 19:54 Back to list

Welded Wire Mesh Size Options from Leading Manufacturers in the Industry

The Importance of Standard Welded Wire Mesh Size A Guide for Manufacturers

Welded wire mesh is a versatile product widely used in construction, agriculture, reinforcement, and various industrial applications. Its design and manufacturing process can vary significantly, depending on the specific needs of its end users. One critical aspect of welded wire mesh is its size, as it greatly influences the performance and applicability of the mesh in different projects. This article will explore the importance of standard welded wire mesh size, examining how it affects quality, functionality, and cost-effectiveness.

Understanding Welded Wire Mesh

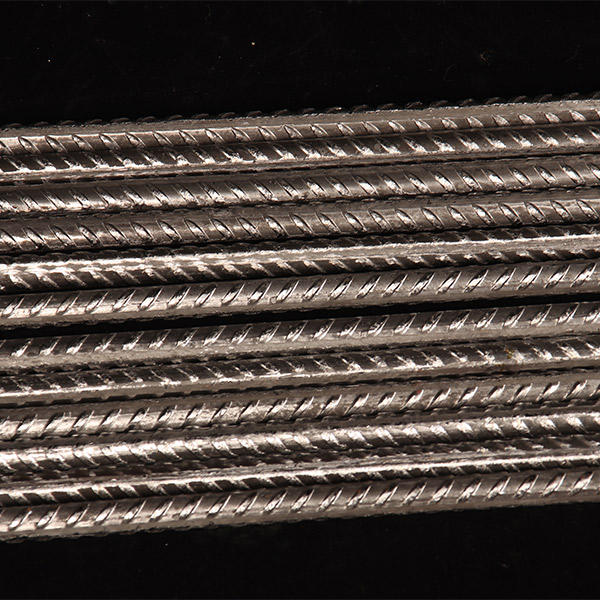

Welded wire mesh is comprised of a series of horizontal and vertical wires that are welded together at their intersections. This process creates a strong and stable framework that can withstand considerable stress and strain. The mesh is typically made from high-quality steel wire, and it is available in various gauges and roll sizes to serve numerous purposes. Understanding the standard sizes and specifications can help both manufacturers and consumers make informed decisions.

The Importance of Standardization

One of the key advantages of standard welded wire mesh sizes is that they promote consistency and reliability across the industry. Standardization means that customers can expect uniformity in product dimensions, wire gauge, and spacing between the welds. This consistency is especially important for large-scale projects that require precise measurements and specifications.

Standard sizes also simplify the purchasing process for manufacturers and contractors. Instead of needing custom orders for each project, customers can choose from readily available options, reducing lead times and streamlining inventory management. This efficiency can result in cost savings, which are crucial in today’s competitive market.

Functionality and Application

Different projects may require specific sizes and configurations of welded wire mesh. For instance, smaller mesh sizes are suitable for applications that involve concrete reinforcement, such as slabs, walls, and foundations, as they help distribute loads evenly. On the other hand, larger mesh sizes are often utilized in fencing, cages, and agricultural applications, where visibility and reduced weight are desirable.

standard welded wire mesh size manufacturer

The choice of welded wire mesh size can significantly impact the overall performance of a structure. If the mesh is too small, it can lead to unnecessary material costs and weight. Conversely, if the mesh is too large, it might not provide adequate support or strength, potentially compromising the integrity of the project. Thus, understanding standard sizes allows manufacturers to select the appropriate mesh for their specific needs.

Factors to Consider in Size Selection

Manufacturers need to consider several factors when selecting the size of welded wire mesh, including

1. Load-Bearing Requirements Depending on the application, the amount of weight and stress the mesh will need to support is critical. Engineers should calculate load expectations to determine the appropriate wire gauge and size.

2. Environmental Conditions Weather and environmental factors might also affect the choice of wire mesh size, especially for outdoor applications that may be exposed to corrosive conditions.

3. Aesthetic Considerations In some projects, such as enclosures or fencing, the visual appeal of the mesh may be a determining factor. Different sizes and patterns can create various visual effects.

4. Regulatory Standards Many regions have specific codes and regulations that dictate the thickness and size of welded wire mesh used in construction and safety applications. Manufacturers must adhere to these standards to ensure compliance.

Conclusion

In summary, the standard welded wire mesh size plays a pivotal role in its application and effectiveness across various industries. Understanding the significance of standardized sizes allows manufacturers and contractors to optimize their projects, enhancing both functionality and cost-effectiveness. By selecting the appropriate mesh size based on load requirements, environmental factors, and regulatory standards, businesses can enhance structural integrity and ensure long-lasting results. Whether using welded wire mesh for construction, agriculture, or industrial purposes, knowledge of standard sizes is essential for success.

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025