ກ.ພ. . 19, 2025 11:33 Back to list

Cold Drawn Wire

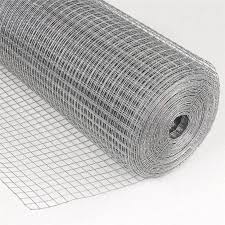

Navigating the landscape of OEM standard welded wire mesh sizes reveals an intricate tapestry woven from engineering precision, market demand, and innovative manufacturing processes. This essential industrial product plays a pivotal role across various sectors, including construction, agriculture, and security, offering optimized solutions tailored to every application’s specific requirements.

Authoritativeness in the field of welded wire meshes is defined by innovation and adherence to international standards. By complying with strict manufacturing codes, companies not only meet regulatory requirements but also instill confidence in their products' consistency and quality. Leading manufacturers leverage advanced technology in their production processes, employing automated machinery to ensure precise welding and consistent mesh formation. These technological advancements differentiate standard products from their bespoke counterparts, making them preferred choices for discerning clients. Trustworthiness of a mesh supplier is critical when considering large-scale projects. The assurance of timely delivery, adherence to specifications, and the provision of post-purchase support underline the reliability expected from leading suppliers. Forming long-term relationships with clients, bolstered by a history of successful project completions and positive feedback, positions a supplier as a trusted partner in the competitive market landscape. In sum, understanding OEM standard welded wire mesh size requires a deep dive into several intersecting domains—market needs, engineering specifications, and manufacturing capabilities. This synthesis of knowledge translates into robust, reliable, and efficient solutions that propel businesses forward, achieving their structural goals with precision and pragmatism. Through the lens of experience, expertise, authoritativeness, and trustworthiness, these mesh solutions continue to evolve, meeting the ever-changing demands of industries worldwide with unfaltering steadfastness.

Authoritativeness in the field of welded wire meshes is defined by innovation and adherence to international standards. By complying with strict manufacturing codes, companies not only meet regulatory requirements but also instill confidence in their products' consistency and quality. Leading manufacturers leverage advanced technology in their production processes, employing automated machinery to ensure precise welding and consistent mesh formation. These technological advancements differentiate standard products from their bespoke counterparts, making them preferred choices for discerning clients. Trustworthiness of a mesh supplier is critical when considering large-scale projects. The assurance of timely delivery, adherence to specifications, and the provision of post-purchase support underline the reliability expected from leading suppliers. Forming long-term relationships with clients, bolstered by a history of successful project completions and positive feedback, positions a supplier as a trusted partner in the competitive market landscape. In sum, understanding OEM standard welded wire mesh size requires a deep dive into several intersecting domains—market needs, engineering specifications, and manufacturing capabilities. This synthesis of knowledge translates into robust, reliable, and efficient solutions that propel businesses forward, achieving their structural goals with precision and pragmatism. Through the lens of experience, expertise, authoritativeness, and trustworthiness, these mesh solutions continue to evolve, meeting the ever-changing demands of industries worldwide with unfaltering steadfastness.

Next:

Latest news

-

Heavy-Duty Welded Wire Mesh for Industrial Factories

NewsAug.04,2025

-

Chain Link Fence - Anping County Puersen | Durable, Versatile, Reliable

NewsAug.03,2025

-

Chain Link Fence: Durable, Versatile, and Reliable Fencing Solution|Galvanized Steel Fence Manufacturers

NewsAug.03,2025

-

Chain Link Fence-Galvanized Steel Fence Factory|Durable, Versatile, Cost-Effective

NewsAug.03,2025

-

Heavy-Duty Welded Wire Mesh for Industrial Factories

NewsAug.03,2025

-

Galvanized Steel Fence-Anping Puersen|Durable,Flexible

NewsAug.02,2025